Commissioning

4.10 Safety Integrated commissioning

Commissioning with Startdrive

Commissioning Manual, 11/2017, 6SL3097-4AA10-0BP1

279

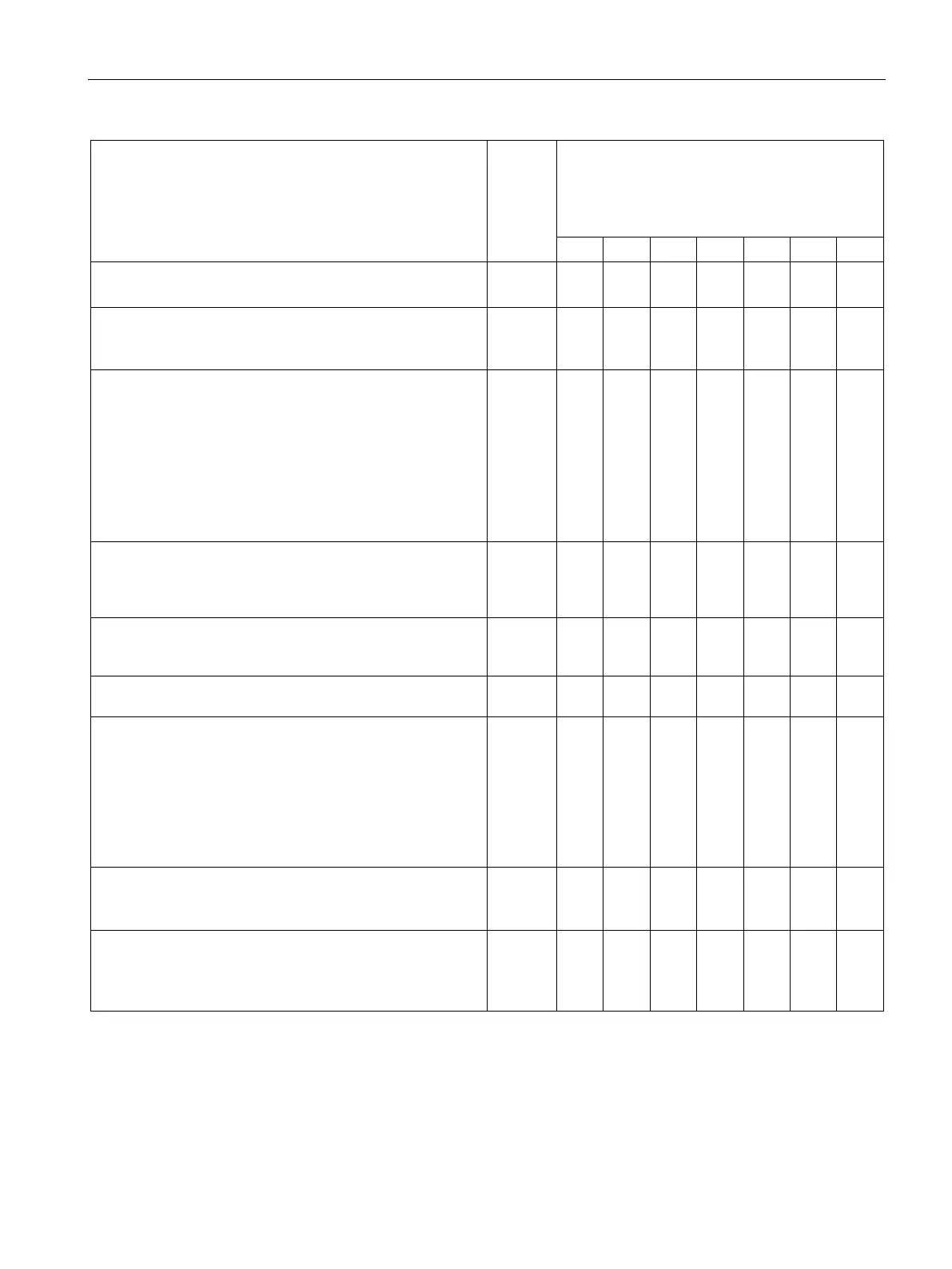

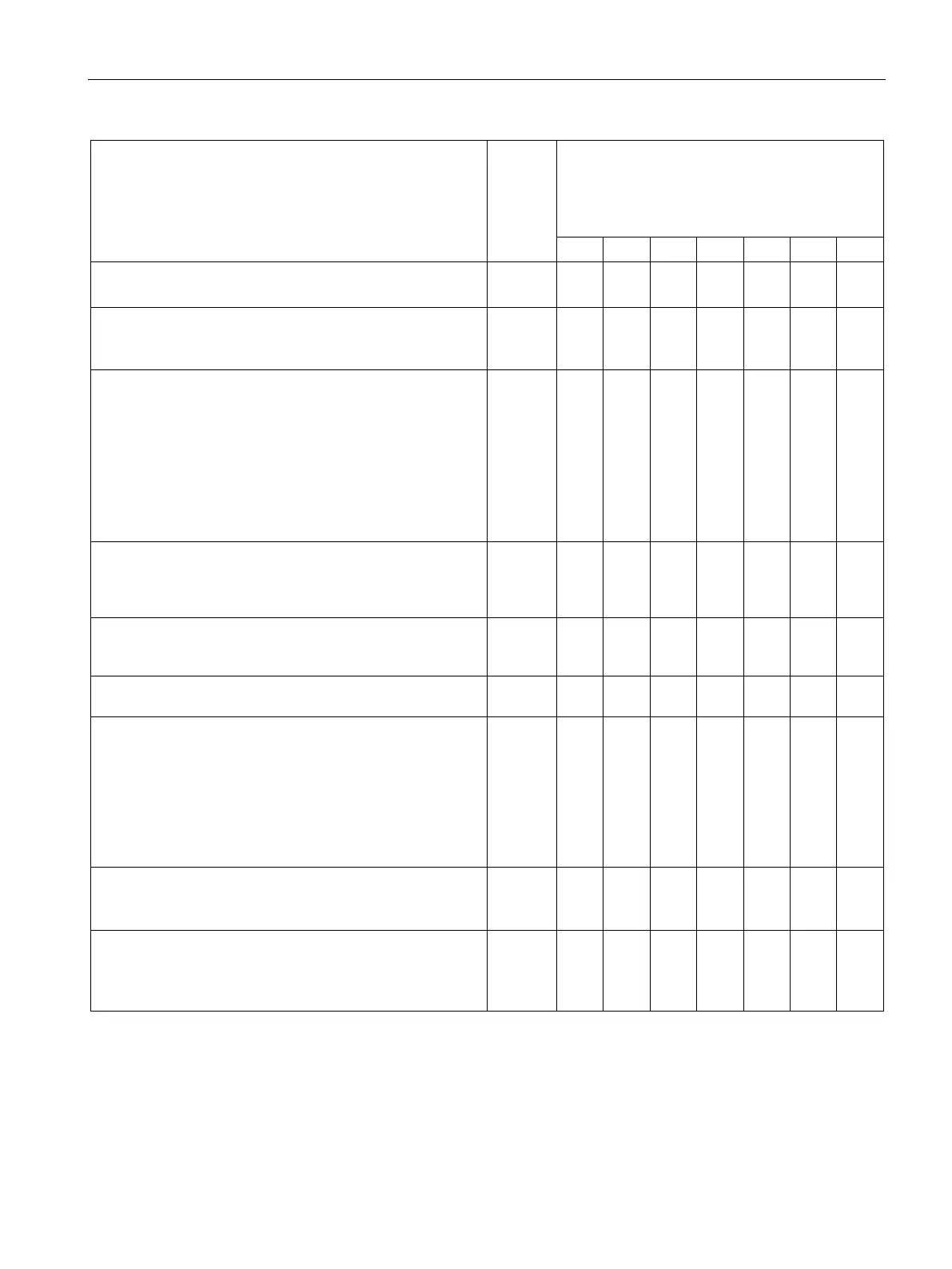

Required for the configuration:

- Encoder system

- Motor type

- Axis type

This field shows the number of pulses of the encoder used.

p9518 x x x x x – –

This field shows the number of bits of the encoder control

p9519 x x x x x – –

Load revolutions / encoder revolutions

In this section you can parameterize a gear ratio for the

encoders used. The gear ratio is the ratio of encoder revolu-

tions to revolutions of the drive shaft (load revolutions).

• "Number of load revolutions" allows you to enter the

number of load revolutions.

• "Number of encoder revolutions" allows you to enter the

number of encoder revolutions.

p9521

p9522

x x x – – x x

Sets the denominator and numerator for the gearbox be-

tween the encoder (or motor for encoderless monitoring

p9321

p9322

x – – – – – –

Here, you parameterize the number of encoder pulses for

the encoder that is used for safe motion monitoring on the

p9318 x – x – x – –

Here, you parameterize the fine resolution for the encoder

that is used for safe motion monitoring on the Motor Module.

p9319 x – x – x – –

The mean value of the actual values of both channels is

calculated cyclically after actual value synchronization has

been activated, for example, for systems or machines with

slip. The maximum slip defined in p9549 is monitored once

per cross-check cycle (r9724).

If "Actual value synchronization" is not enabled, the value

parameterized in p9542 is used as tolerance value for the

p9501.3 x – x – x – –

Here, you set the tolerance for the crosswise comparison of

the actual position between the two monitoring channels

p9542 x – x – x x x

Here, you set the maximum tolerance for the crosswise

comparison of the actual velocity (only if actual value syn-

chronization has been activated).

p9549 x – x – x – –

Loading...

Loading...