Bit 9 Diameter display for face axis - wear. The wear value of the transverse axis is displayed as

a diameter value, if a transverse axis is defined in MD20100 $DIAMETER_AX_DEF and

SD42940 $TOOL_LENGTH_CONST is set to 18 and SD42950 $TOOL_LENGTH_TYPE is

set to 2.

Bit 10 Enable tool load/relocate to buffer storage locations. The magazine number can be entered

into the load dialog box. It is therefore possible to access the buffer storage via magazine

number 9998.

Bit 11 Creating new tools at gripper locations is blocked.

Bit 12 Measuring tools are not unloaded with the "Unload all" function.

Bit 13 The wear value is not deleted when a tool geometry value is entered.

Bit 14 Load or relocate tool. Empty location search performed without default value with the tool

magazine last used.

= 0 Empty location always starts with the tool magazine last used.

= 1: Empty location search follows the set search strategy.

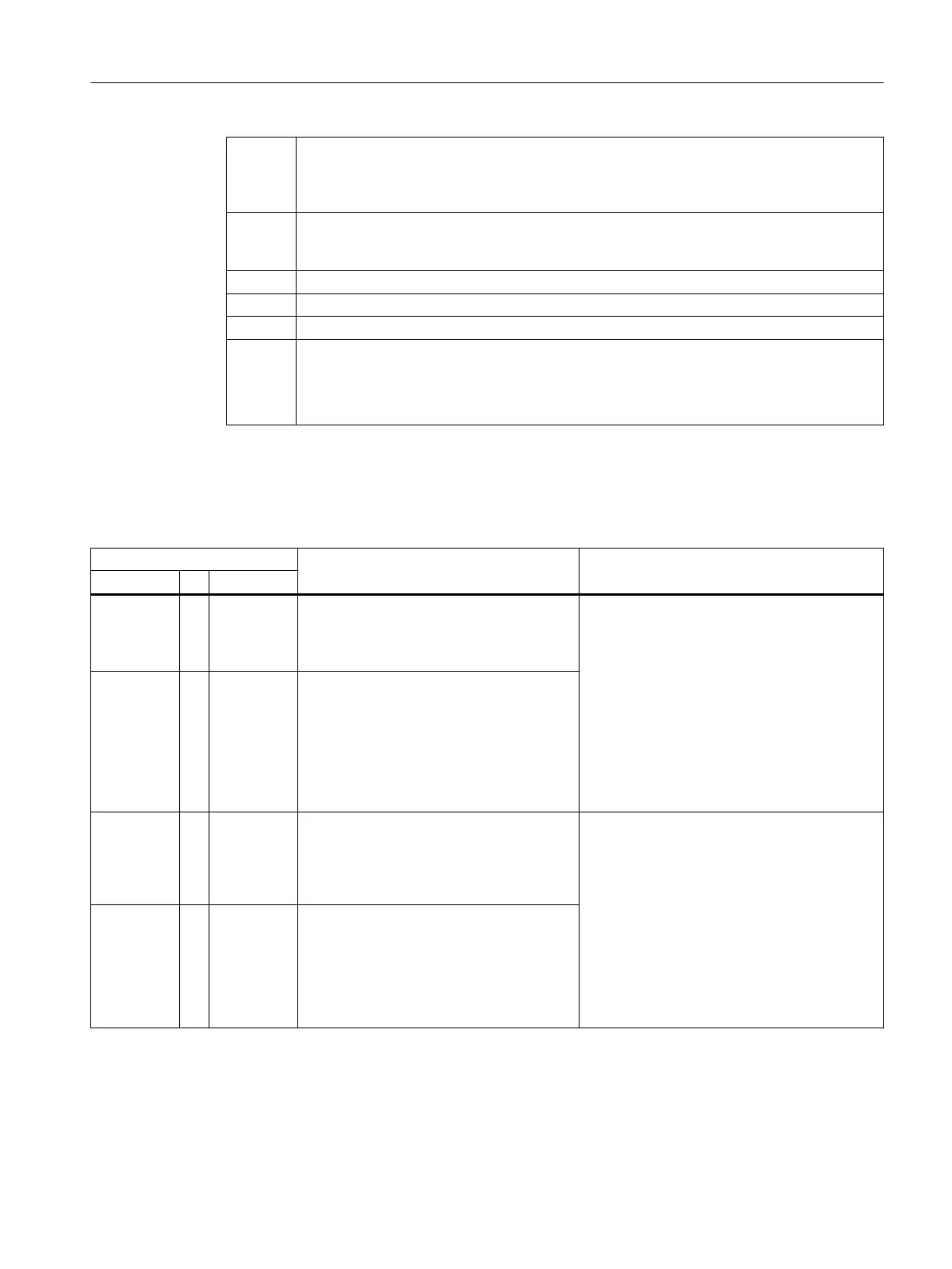

Dependencies

The setting data SD54215 $TM_FUNCTION_MASK_SET and the machine data MD20360

$TOOL_PARAMETER_DEF_MASK have the following dependencies:

Dependency Description Recommendation

SD54215 ⇔ MD20360

Bit 9 ⇔ Bit 0 If bit 0 is set in MD20360, then SD54215

bit 9 has no effect because the NC already

returns the linear wear value of the trans‐

verse axis as a diameter value.

It is recommended that the setting MD20360

bit 0 and bit 1 not be used.

Instead, use SD4215 bit 9 and bit 8.

MD20360 bit 0 and bit 1 are effective only for

turning and grinding tools. This setting there‐

fore cannot be used on a turning/milling ma‐

chine because the linear component of the

transverse axis applies for turning tools in the

diameter and for milling tools in the radius.

When the setting data is used, only the display

goes to diameter, the internal value in the NC

remains at radius.

Bit 8 ⇔ Bit 1 If bit 1 is set in MD20360, then SD54215

bit 8 has no effect because the NC already

returns the linear geometry value of the

transverse axis as a diameter value.

Bit 0 ⇔ Bit 11 If bit 11 is set in MD20360, then SD54215

bit 0 has no effect with regard to cutting

edge parameter 6 (tool nose radius) be‐

cause the NC already returns the tool nose

radius as a diameter value.

It is recommended that the setting MD20360

bit 11 and bit 12 not be used.

Instead, set bit 0 in SD54215.

MD20360 bit 11 and bit 12 apply to all tool

types, i.e. also to turning tools. This setting

therefore cannot be used on a turning/milling

machine because the tool nose radius of a

turning tool should never be specified in the

diameter.

When the setting data is used, only the display

goes to diameter, the internal value in the NC

remains at radius.

Bit 0 ⇔ Bit 12 If bit 12 is set in MD20360, then SD54215

bit 0 has no effect with regard to cutting

edge parameter 15 (wear radius) because

the NC already returns the wear radius as

a diameter value.

Tool management

12.1 Machine data for tool management

SINUMERIK Operate (IM9)

Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1 167

Loading...

Loading...