● Configuring the "Load Station Selection" window

● Coolant and tool-specific functions

● Reason for the tool change when reactivating

● Configure the code carrier connection

● Configuring store to file

The following sections explain how you configure these adaptations.

Procedure

1. Open the directory: /siemens/sinumerik/hmi/template/cfg.

2. Copy the "oem_sltmlistconfig.xml" template file

3. Copy the file to the directory /oem/sinumerik/hmi/cfg

OR: /user/sinumerik/hmi/cfg.

4. Change the file name according to the set technology:

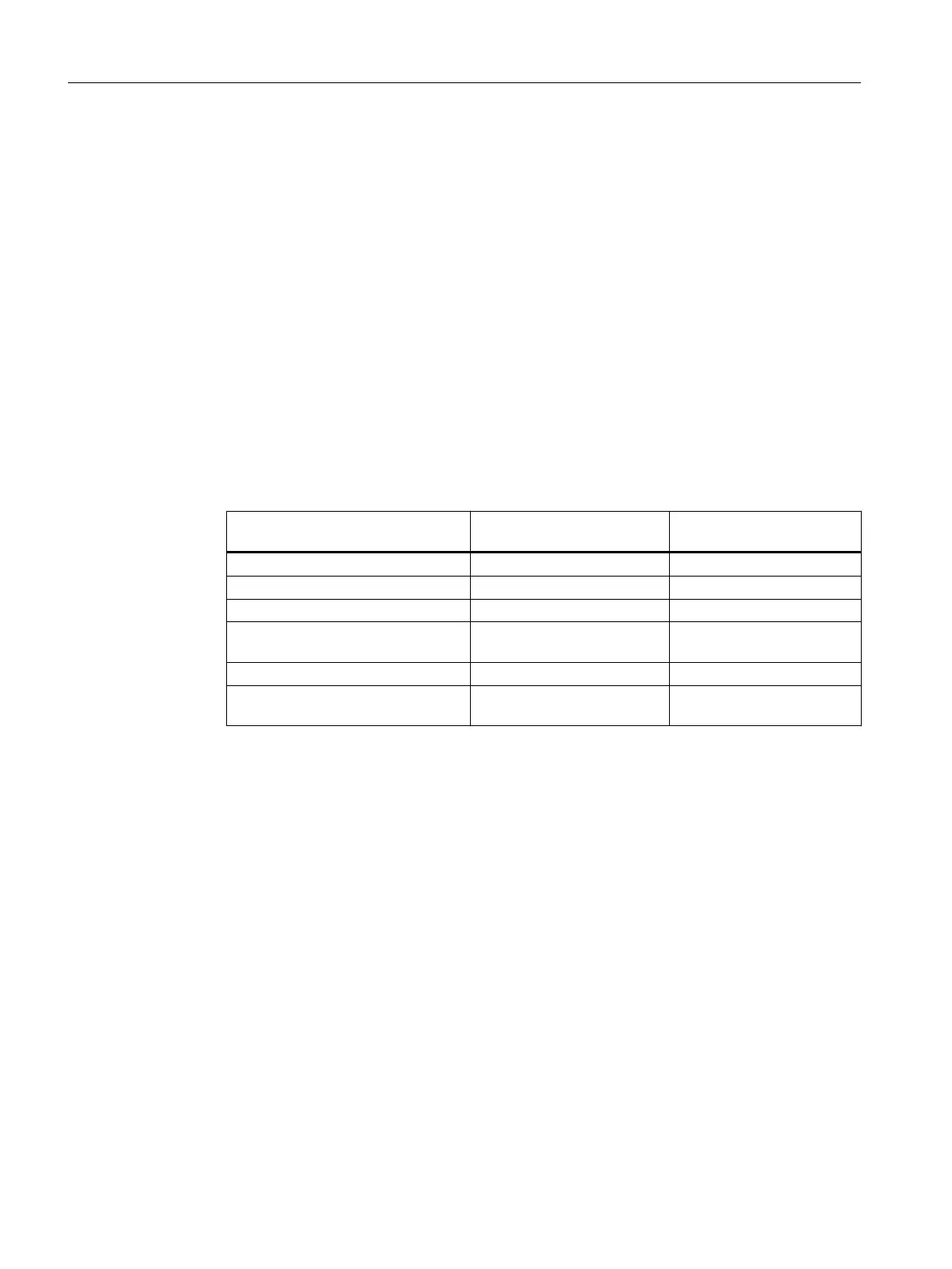

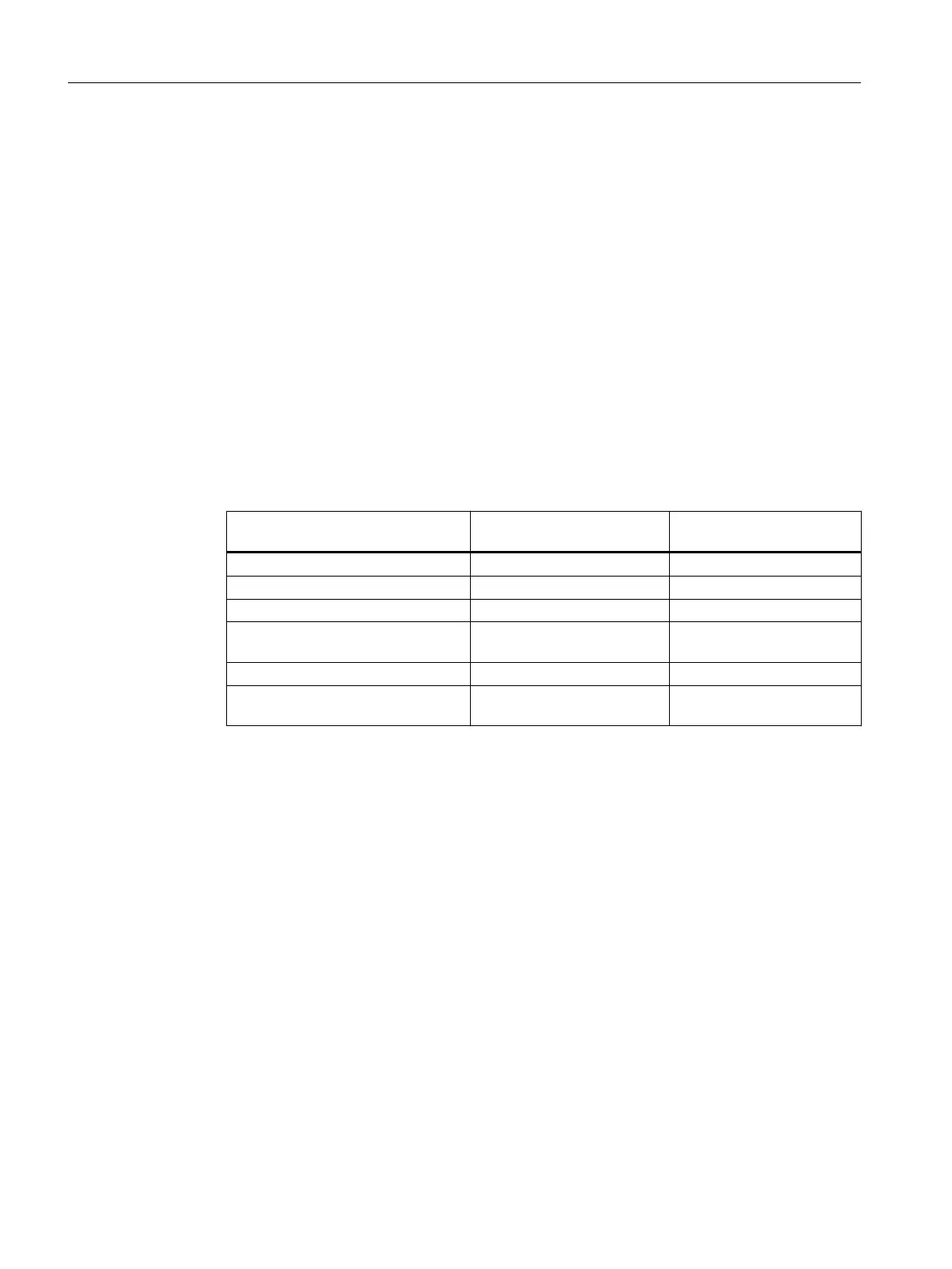

File name MD52200 technology MD52201 technology exten‐

sion

sltmlistconfig.xml Milling technology

sltmturninglistconfig.xml Turning technology

sltmmillturnlistconfig.xml Milling technology Turning technology

sltmcirculargrindinglistconfig.xml Cylindrical grinding technolo‐

gy

sltmsurfacegrindinglistconfig.xml Surface grinding technology

sltmplclistconfig.xml PLC tool management

"TRANSLINE 2000"

5. Remove the comments of the example in the template to create your specific configuration.

Configuration examples

Examples for all possible configurations are provided in the template oem_sltmlistconfig.xml,

which are described individually in the following sections:

<?xml version="1.0" encoding="UTF-8" standalone="yes"?>

- <CONFIGURATION>

<!--

<!--

<!--

************************************************************-->

enter your configuration behind this comment -->

************************************************************** -->

Configuration examples

<!--

<!--

<!--

************************************************************** -->

enter your configuration ahead this comment -->

************************************************************** -->

</CONFIGURATION>

Tool management

12.2 Configuring the user interface

SINUMERIK Operate (IM9)

170 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...