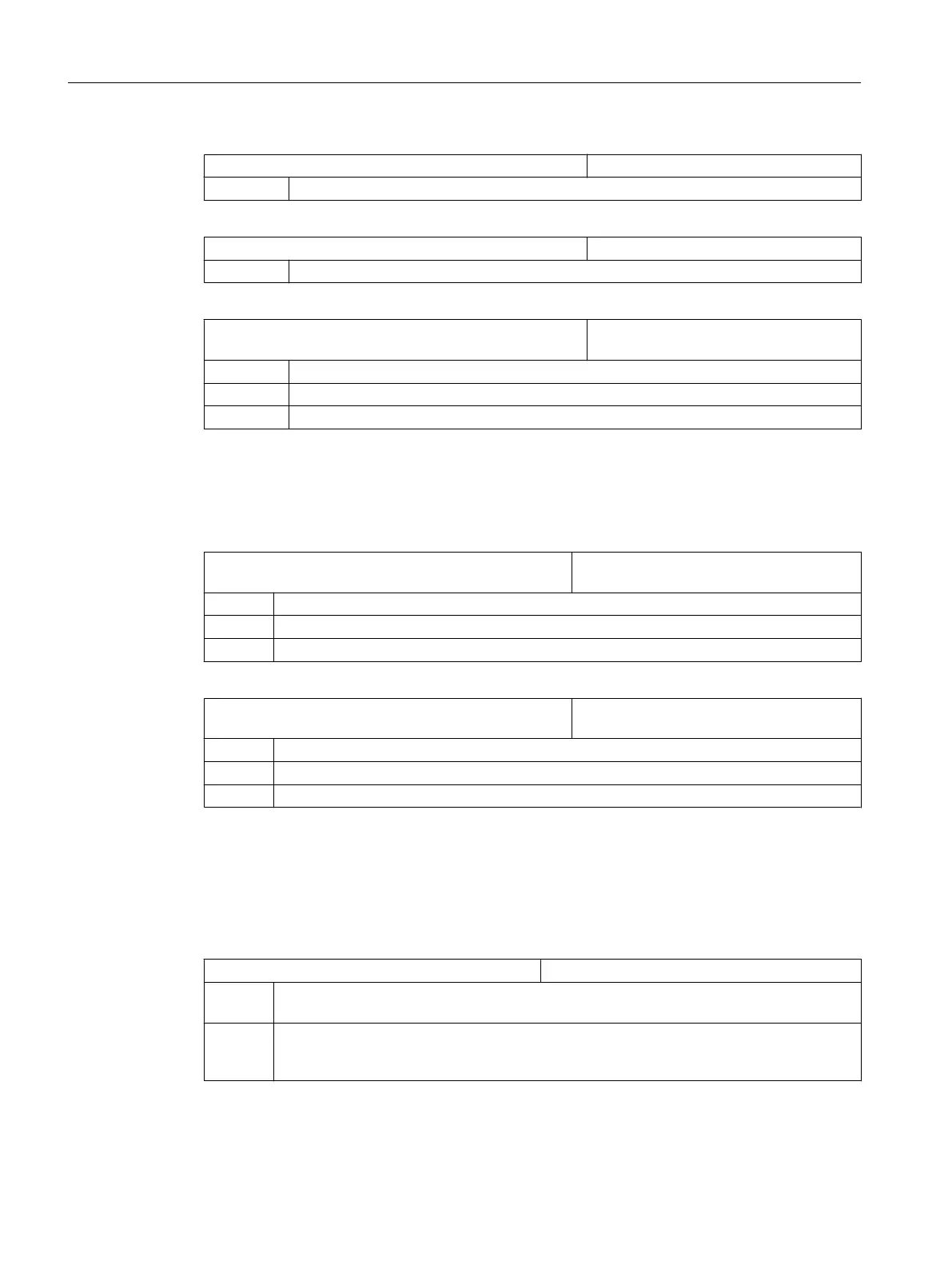

MD24910 $MC_TRANSMIT_ROT_SIGN_IS_PLUS_1

= 0 Sign of the rotary axis for the 1st TRANSMIT transformation.

MD24911 $MC_TRANSMIT_POLE_SIDE_FIX_1

= 1 Limitation of working range in front of/behind the pole, 1st TRANSMIT.

MD24920 $MC_TRANSMIT_BASE_TOOL_1[ ] Vector of the base tool for the 1st TRANS‐

MIT transformation.

[0] = 0

[1] = 0

[2] = 0

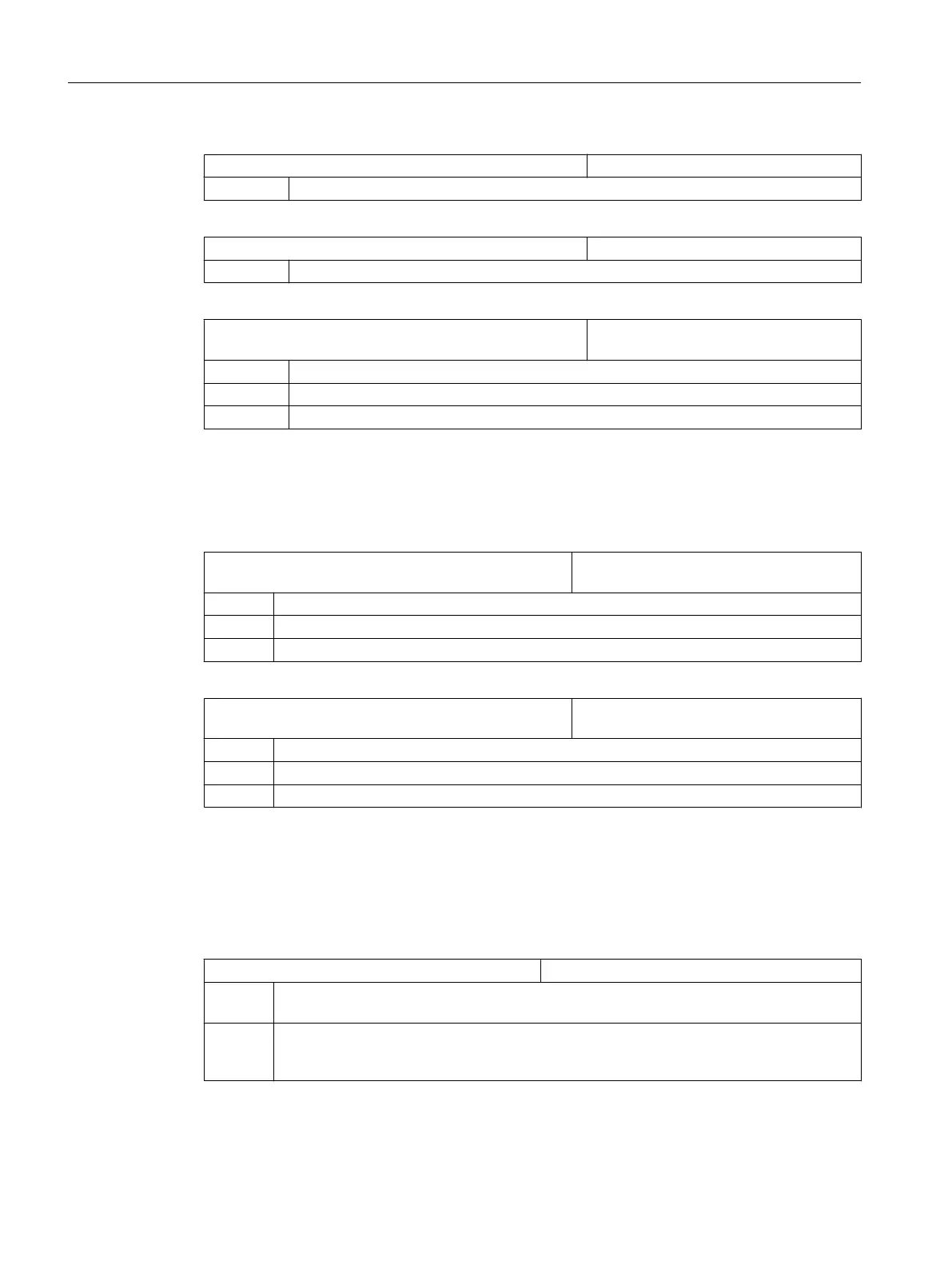

Additional settings for rotary axes

If you want to integrate rotary axes, in addition to the following machine data you also require

MD28082 with bit 6, see Chapter "Cylinder surface transformation (TRACYL) (Page 544)".

MD24906 $MC_TRANSMIT_BASE_TOOL_COMP_1 Compensation of the basic offset in the 1st

transformation frame.

Bit 0 1st geometry axis

Bit 1 2nd geometry axis

Bit 2 3rd geometry axis

MD24956 $MC_TRANSMIT_BASE_TOOL_COMP_2 Compensation of the basic offset in the 2nd

transformation frame.

Bit 0 1st geometry axis

Bit 1 2nd geometry axis

Bit 2 3rd geometry axis

For further information, see also Chapter "Clamping a blank (Page 142)".

Face machining under ShopTurn

If you wish to use the face machining function under ShopTurn function, set the following

additional channel-specific configuration machine data:

MD52214 $MCS_FUNCTION_MASK_MILL Function screens, ShopTurn.

Bit 3 Enable "internal / rear" machining in ShopTurn screens that define the machining plane

themselves.

Bit 4 If you have implemented the "Clamp/release spindle" function using the machine manufac‐

turer cycle CUST_TECHCYC.SPF, then using this machine data, you can activate the

"Clamp/release spindle" parameter in the drilling and milling screens.

Technologies and cycles

21.5 Turning

SINUMERIK Operate (IM9)

550 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...