Resource-Consumption Supervision

Load Model

SIPROTEC 5 devices are freely configurable. A load model is integrated in DIGSI 5. The load model prevents you

from overloading the device with an excessively large application.

The load model shows the device utilization and the response times for device functions. If it determines that

an application created is likely to overload the device, DIGSI prevents the application from being loaded into

the device.

In this rare case, you must then reduce the application in order to be able to load it into the device.

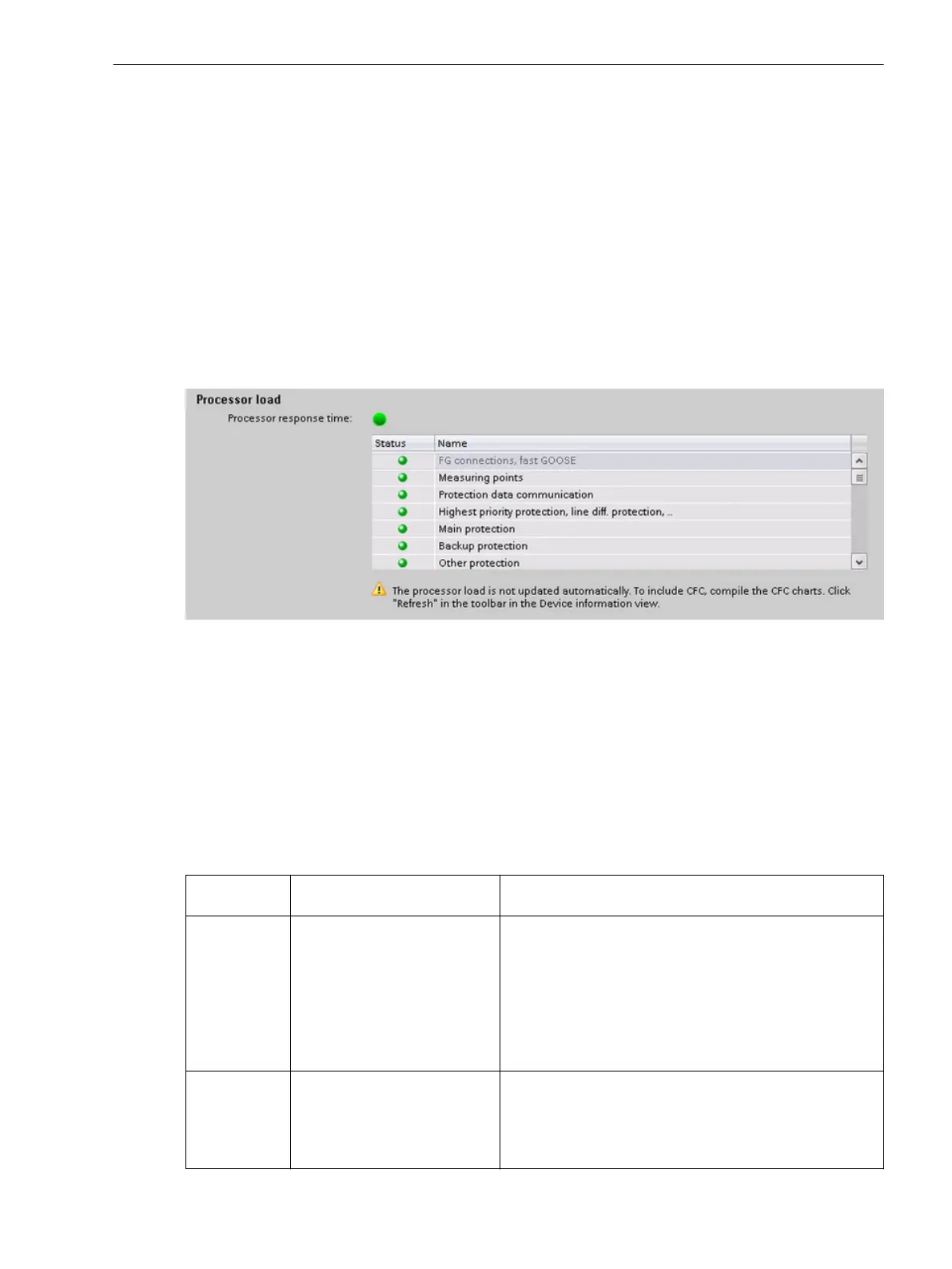

The load model can be found in the DIGSI 5 project tree under Name of the device → Device information. In

the operating range, select the Resource consumption setting sheet. The following figure shows an example

of the view of the load model in DIGSI 5:

[scressou_n, 1, en_US]

Figure 8-1 Visualization of the Load Model in DIGSI

A green total display for the processor response time indicates that the device is not overloaded by the present

application. On the other hand, if you see a red exclamation mark, the planned application is overloading the

device.

The list below the total display shows the individual functional areas. These areas combine functions with the

same real-time requirements in groups. A green display in front of an area (see Figure 8-1) indicates that the

response times of the functions grouped in this area can be maintained. A red exclamation point indicates that

functions may have longer response times than are specified in the Technical data for the device. In such a

case, loading of the application into the device is blocked.

The following table provides an overview of the functional areas and the most important influencing quanti-

ties on device utilization:

Functional

Area

Brief Description Change in Load

CFC event-trig-

gered, fast

CFC-charts, which must be

processed especially fast

Adding or removing CFC charts in the fast event-triggered

process range

•

Create CFC chart

•

Delete CFC chart

•

Change the process range in the properties of the CFC

chart

Add to or remove from CFC charts in the fast event-trig-

gered process area

Measuring

points

Provision of measured values

for measuring functions

Adding or removing

•

Measuring points (in the Measuring-points routing

Editor)

•

Function groups that provide measured-value prepro-

cessing for insertable functions

8.2

8.2.1

Supervision Functions

8.2 Resource-Consumption Supervision

SIPROTEC 5, Fault Recorder, Manual 363

C53000-G5040-C018-5, Edition 11.2017

Loading...

Loading...