5-76 4203780 First Edition

HYDROSTATIC POWER TRAIN

5

Determine Shim Thickness

There are two possible methods for determining the

thickness of shims needed for the right differential

housing. Review each procedure to determine which

method best fits your application.

Method “A”

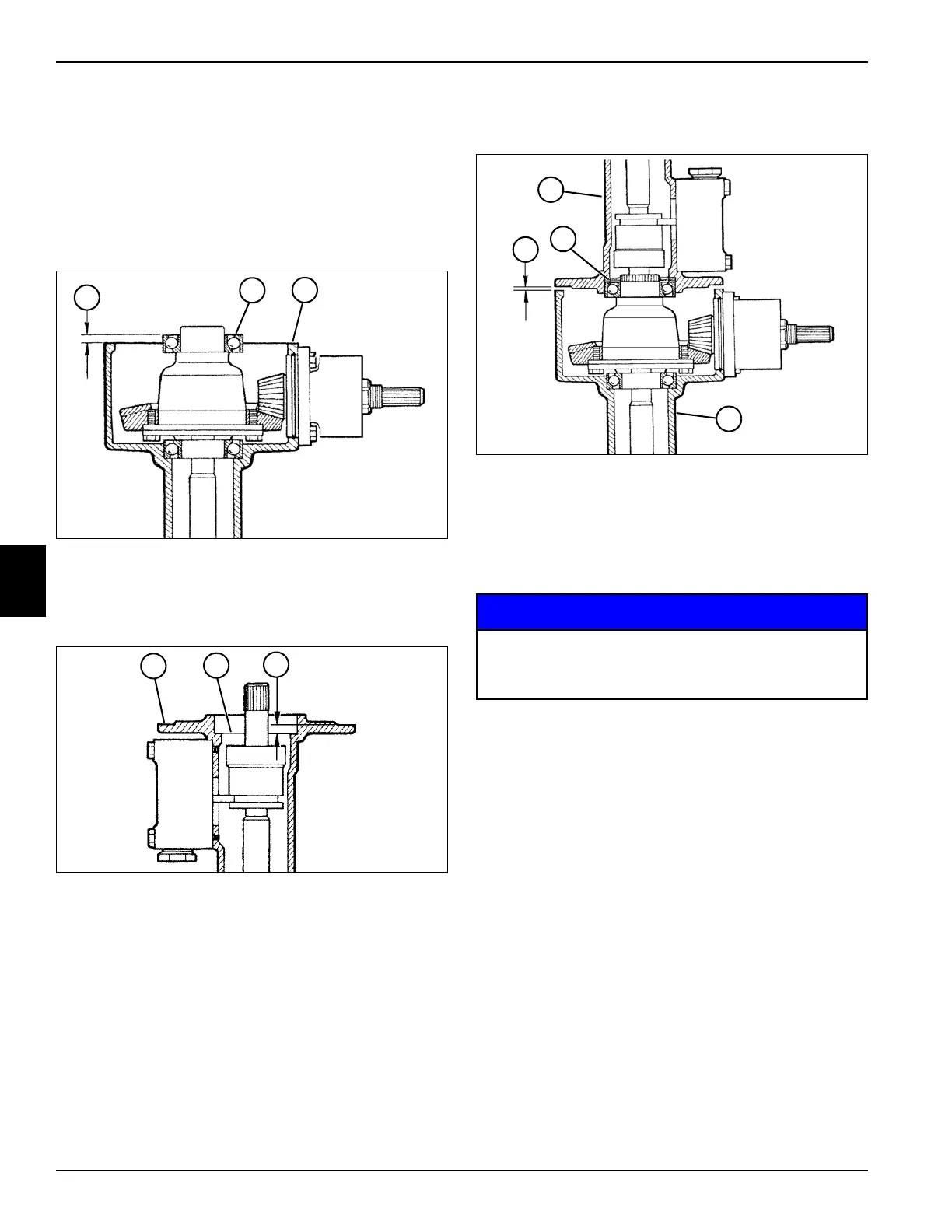

See Figures 5-85 and 5-86.

Figure 5-85

1. Measure the distance (1) from the side of the

differential bearing (2) to the housing flange surface

(3).

Figure 5-86

2. Measure the distance (6) from the right differential

housing flange (4) to the bottom of the bearing bore

(5).

3. Subtract distance (1) from distance (6). From the

answer, add 0.004 in. (0.1 mm). This is the thickness

of the shim pack needed.

4. Continue assembly of the differential housings, step

11 of “Assembly” on page 5-74.

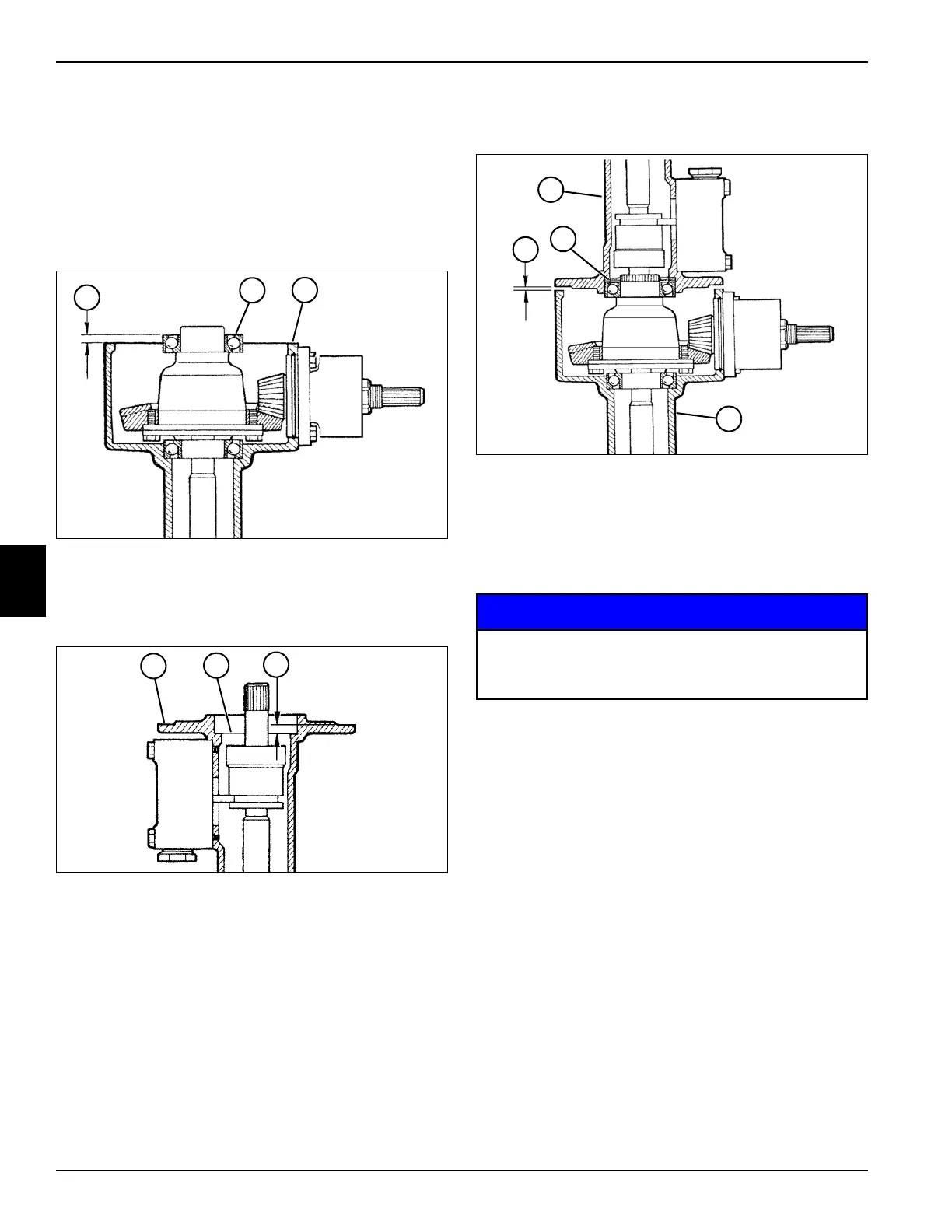

Method “B”

See Figure 5-87.

Figure 5-87

1. Build a temporary shim pack (2) equal to 0.030 in.

(0.76 mm), and place it on the bearing bore of the

right differential housing (1).

2. Place the right differential housing (1) on the left

differential housing (4).

NOTICE

3. Install the differential housing bolts evenly to hand

tight.

4. Using a feeler gauge, measure the gap (3) between

the housings.

5. Add 0.004 in. (0.1 mm) to the dimension obtained in

step 3, then subtract the total from 0.030 in.

(0.76 mm). This is the thickness of the shim pack

needed.

6. Separate the differential housings.

7. Remove the temporary shim pack (2).

8. Continue assembly of the differential housings, step

11 of “Assembly” on page 5-74.

TN1934

1

2

3

TN1935

4

6

5

Tightening the differential housing bolts at this

time could result in damage to the differential

housings or other components.

TN1939

3

2

1

4

Loading...

Loading...