Chapter 9

161

UM10372_PCNC440_Manual_0221A

MAiNTENANCE

9.1.5 Drawbar and TTS Collet

The drawbar, drawbar bushing, and TTS collet are wear items and should be replaced regularly.

Proper lubricaon and maintenance of the drawbar, drawbar bushing, and TTS collet will maximize

tool holding force and prolong the service life of these components.

• Clean tool holder shanks as needed with a degreaser

• Ensure inside of collet is clean and dry; remove preservave shipping oil when rst received

• Lubricate outside of collet and inside of spindle taper with An-seize Grease (PN 31273). Use

sparingly to avoid risk of the lubricant migrang to the inside of the collet. Only the rst inch

of the spindle taper needs to be lubricated; remove excess lubricant with a degreaser.

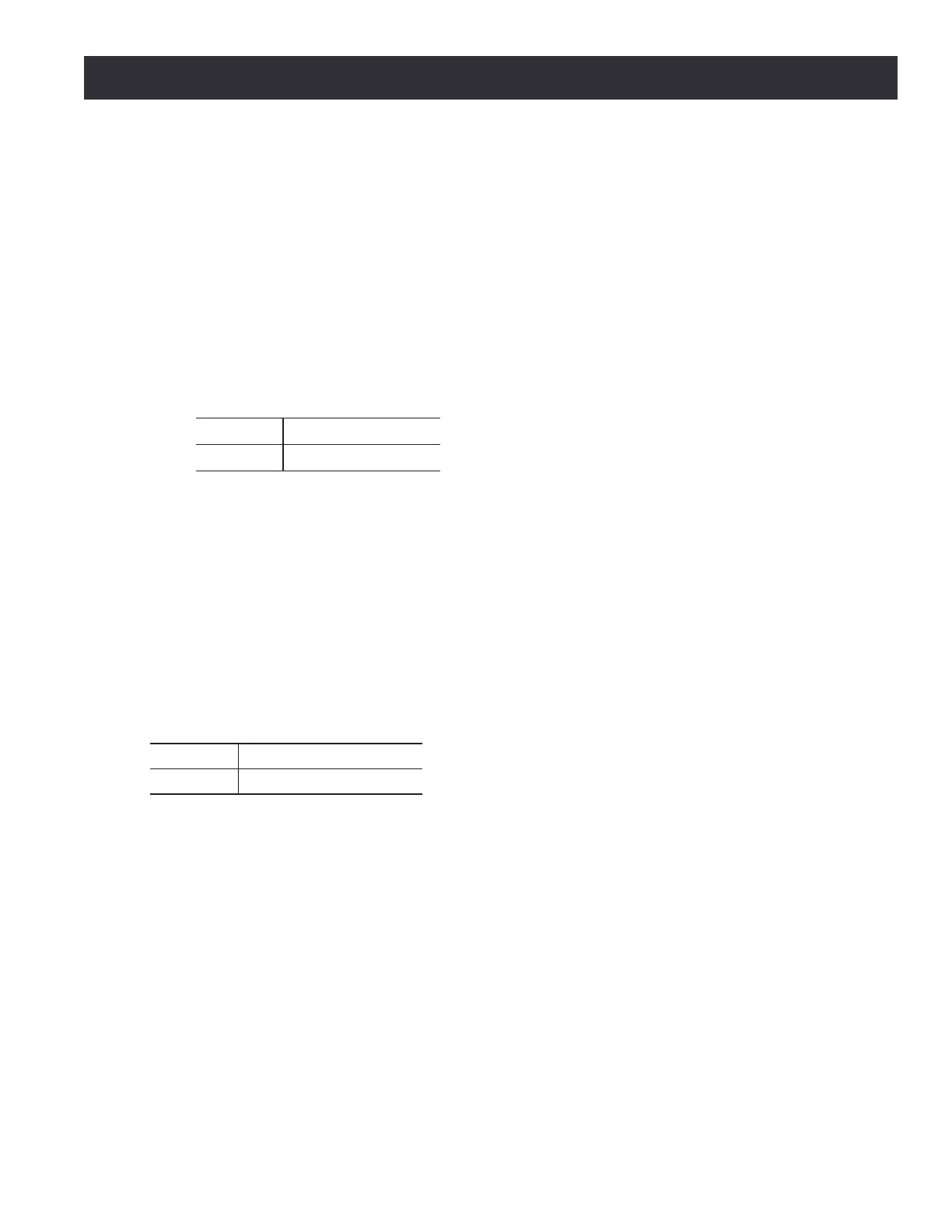

PN Description

31273 An-seize Grease

• Lubricate the threaded secon of the drawbar, the thrust shoulder of the drawbar, and the

drawbar bushing with An-seize Grease (PN 31273)

• Do not overghten the drawbar; the recommended drawbar torque is 30 -lbs, and exceeding

40 -lbs of torque will reduce the operaonal service of the collet and drawbar

• Visually inspect the drawbar, drawbar bushing, and collet for signs of wear such as damaged

or galled threads and replace as needed; it is recommended that these be replaced as a set

9.2 Spindle Belt

Inspect the spindle belt as indicated in the maintenance schedule. Replace if necessary.

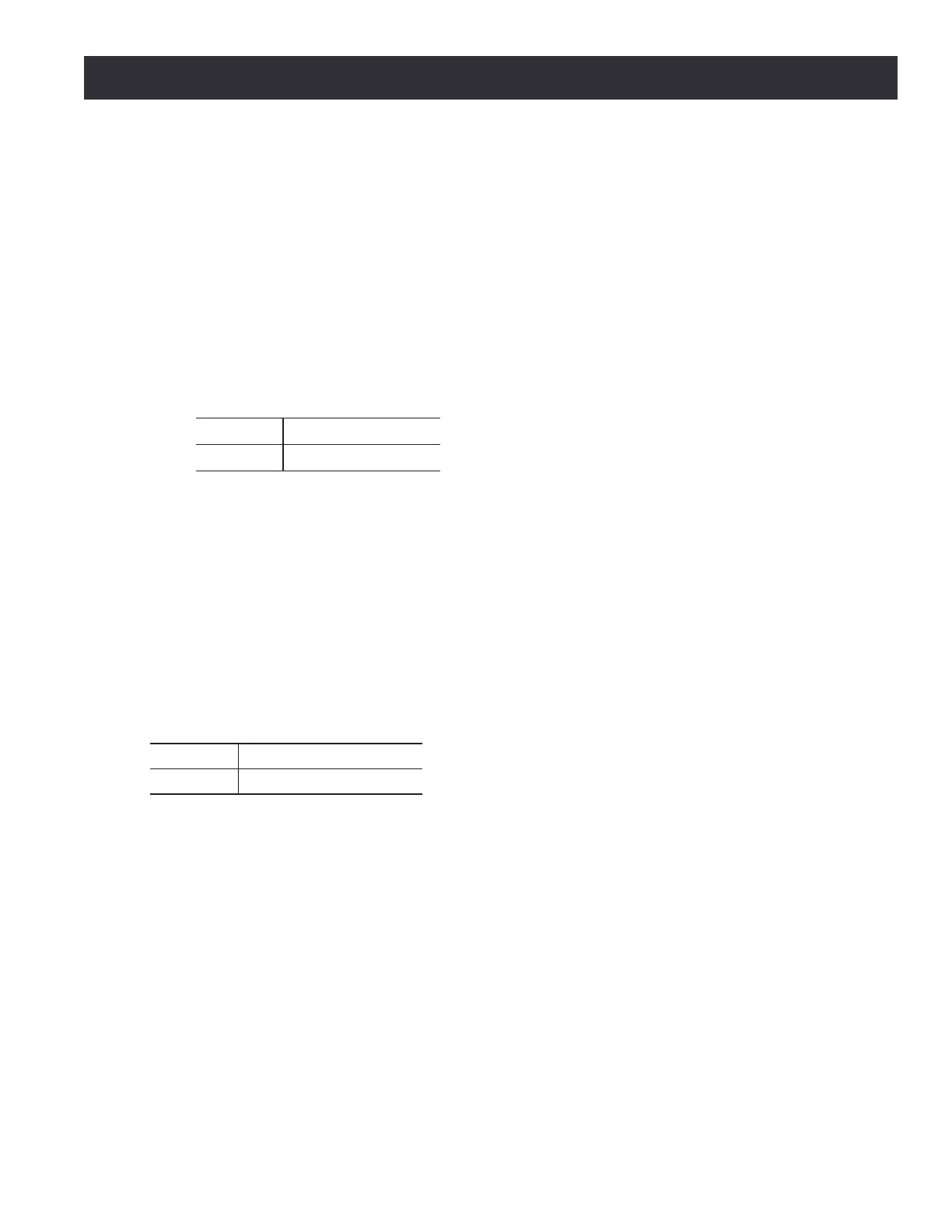

PN Description

35799 PCNC 440 Spindle Belt

9.3 Advanced Maintenance

9.3.1 Overview

Each PCNC 440 is tuned at the factory to meet or exceed certain precision metrics. These metrics

are indicated on the Cercate of Inspecon included with each mill, along with the actual values

measured for each metric as part of Tormach’s Quality Assurance program. The following advanced

maintenance procedures may become necessary over the ownership lifeme to maintain the

original factory precision:

• Gib adjustment

• Angular contact bearing preload adjustment

• Geometry adjustment (tram)

Loading...

Loading...