Chapter 3

27

UM10372_PCNC440_Manual_0221A

iNSTAllATiON

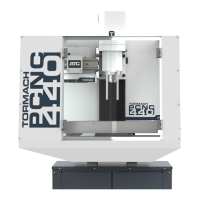

3.3.4 Attach Mill to Stand

WARNING! Crush Hazard: Keep hands

and body parts clear when lowering mill onto

stand. Failure to do so could result in death and/

or serious injury.

1. Place the oponal chip pan (PN 35673) on

top of oponal stand (PN 35671).

2. Lower mill slowly while lining up holes in

chip pan, mill, and stand (see Figure 3.5).

3. Using four M12 x 100 mm studs, washers,

and nuts, aach chip pan, mill, and stand

together; ghten nuts securely.

3.3.4.1 Non-Tormach Stands

If an alternave stand is used, ensure:

• Stand has a minimum weight capacity of

1000 lbs

• Mill is securely connected to stand

• Stand is stable and secure

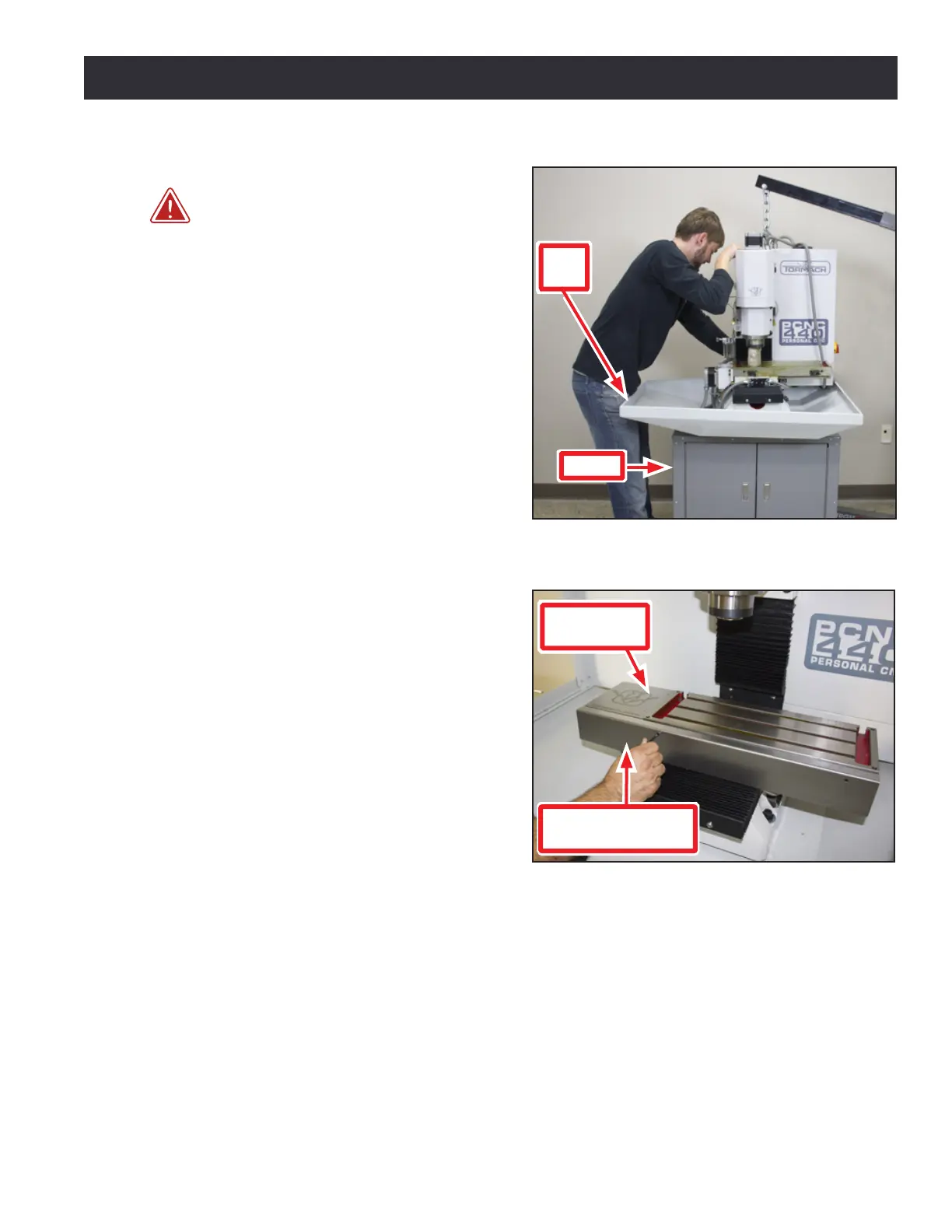

3.3.5 X-axis Motor Cover Plate

Install the X-axis Motor Cover Plate using

provided screws to aach it to le side of

machine table (see Figure 3.6).

3.3.6 X-axis Limit Switch Cover Plate

Install the X-axis Limit Switch Cover Plate using

provided screws to aach it to front of machine

table (see Figure 3.6).

3.3.7 Manual Oiler

Retract and release plunger unl oil moves through system. Aer that, pull plunger each me mill

is powered on and aer every four hours of operaon. For more informaon on providing oil to the

machine, refer to chapter 9, Maintenance.

3.3.8 Flood Coolant System

Fill the reservoir with pre-mixed coolant; refer to diluon instrucons for coolant product.

For informaon on installaon and use of the oponal Flood Coolant Kit (PN 35719), refer to

documentaon that ships with the product.

Figure 3.5

Chip

Pan

Stand

Figure 3.6

X-axis Motor

Cover Plate

X-axis Limit

Switch Cover Plate

Loading...

Loading...