Chapter 5

46

UM10372_PCNC440_Manual_0221A

iNTRO TO PATHPilOT

5.1.6 Touch Off the Workpiece to Set Work Offsets

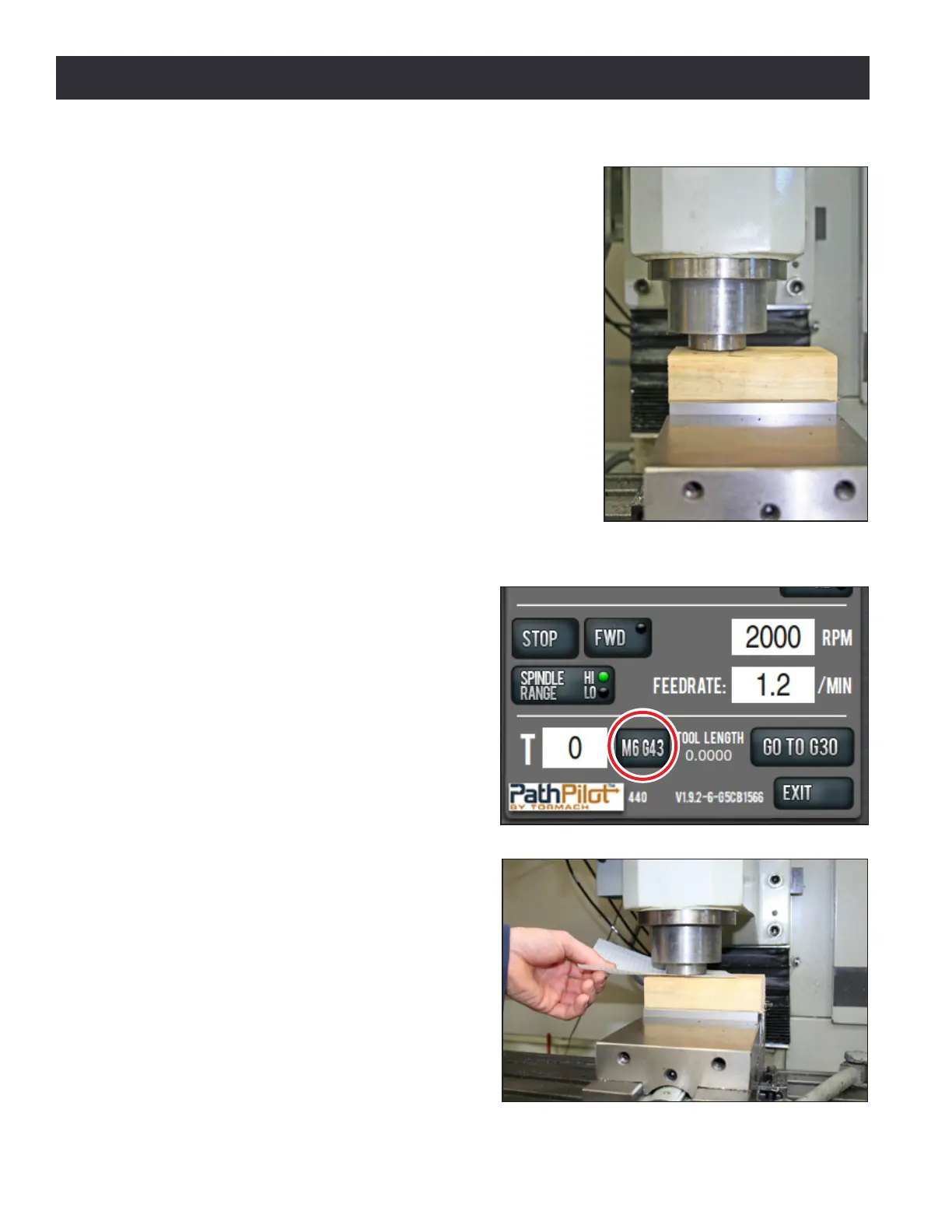

There are many ways of conceptualizing tool and work

osets, but we use the idea of a true posive tool length to

demonstrate this rst part program. When using this method

we will touch the face of the spindle to the top of the workpiece

to set the work Z zero (see Figure 5.4). If you set your work Z

zero using the face of the empty spindle then touch your tools

o to the same work zero, the tool length osets are equal in

value to the length of the tool. True posive tool length has a

few benets over other methods (i.e., relave tool lengths) of

measuring tool osets:

• You can easily look at the tool length oset value

and esmate whether it is correct for a given tool by

checking that tool with a ruler or calipers.

• You can mix tools that have been touched o on the

mill with tools that have been measured using a digital

height gauge.

• It is conceptually easier to understand.

Seng the Z Work Oset

1. If a tool is in the spindle, remove the tool

from the spindle.

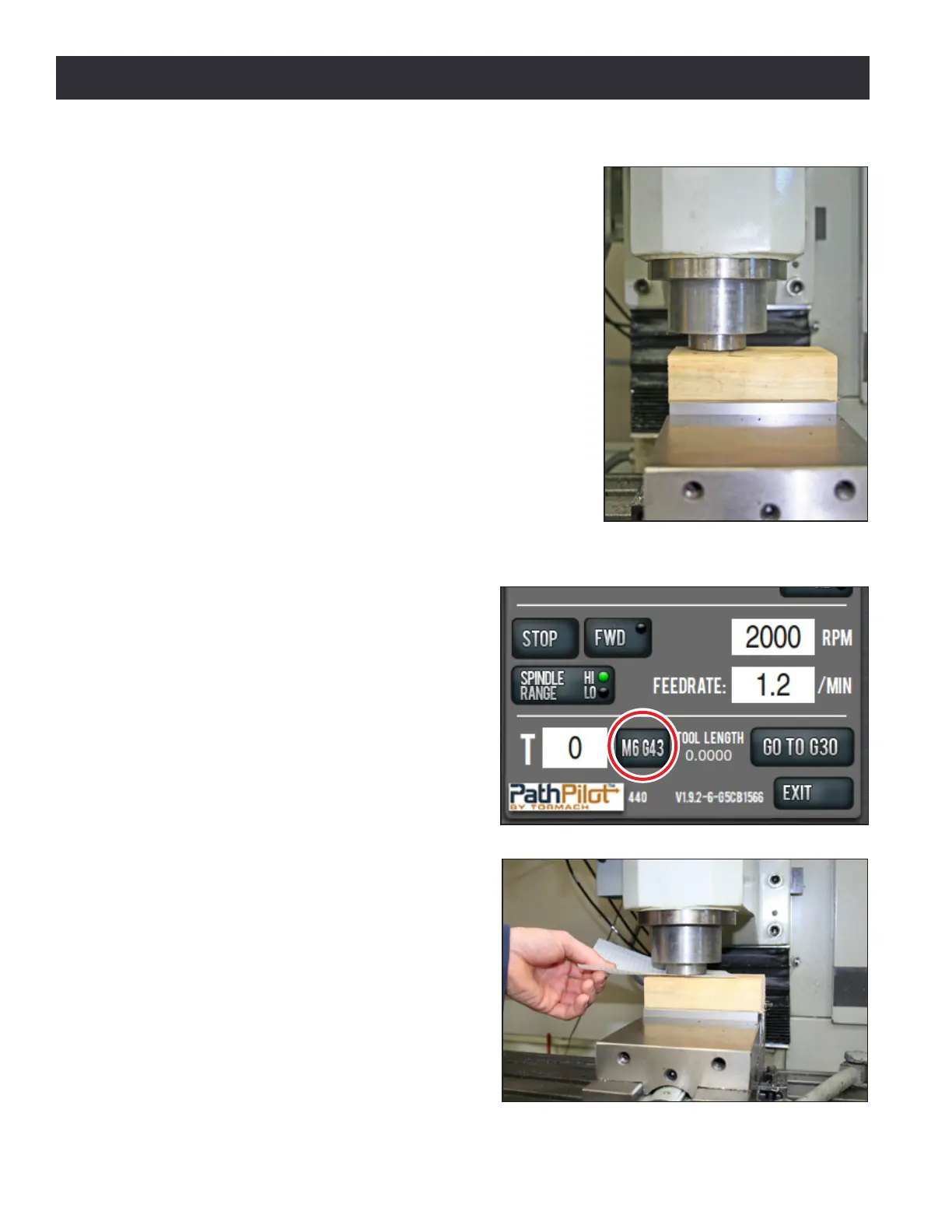

2. Type 0 in the tool DRO and press the M6

G43 buon to tell the PathPilot operang

system that we are changing tools and

applying a tool length oset. Tool zero

represents an empty spindle, and there

is no oset to apply. We press the M6

G43 buon to make sure there is no tool

length oset applied before we set the

work oset (see Figure 5.5).

3. Place a piece of scrap 2” x 4” in vise. Make

sure that the top of 2” x 4” is at least 1/4”

above the top of the vise jaws.

4. Place a piece of paper on the 2” x 4” and

jog the spindle down carefully unl the

spindle nose just makes contact with the

top of the piece. You will be able to feel

when the paper is pinched (see Figure 5.6).

Figure 5.4

Figure 5.6

Figure 5.5

Loading...

Loading...