Chapter 6

78

UM10372_PCNC440_Manual_0221A

PATHPilOT iNTERFACE

6.8.1.1 Adjusting DRO Values

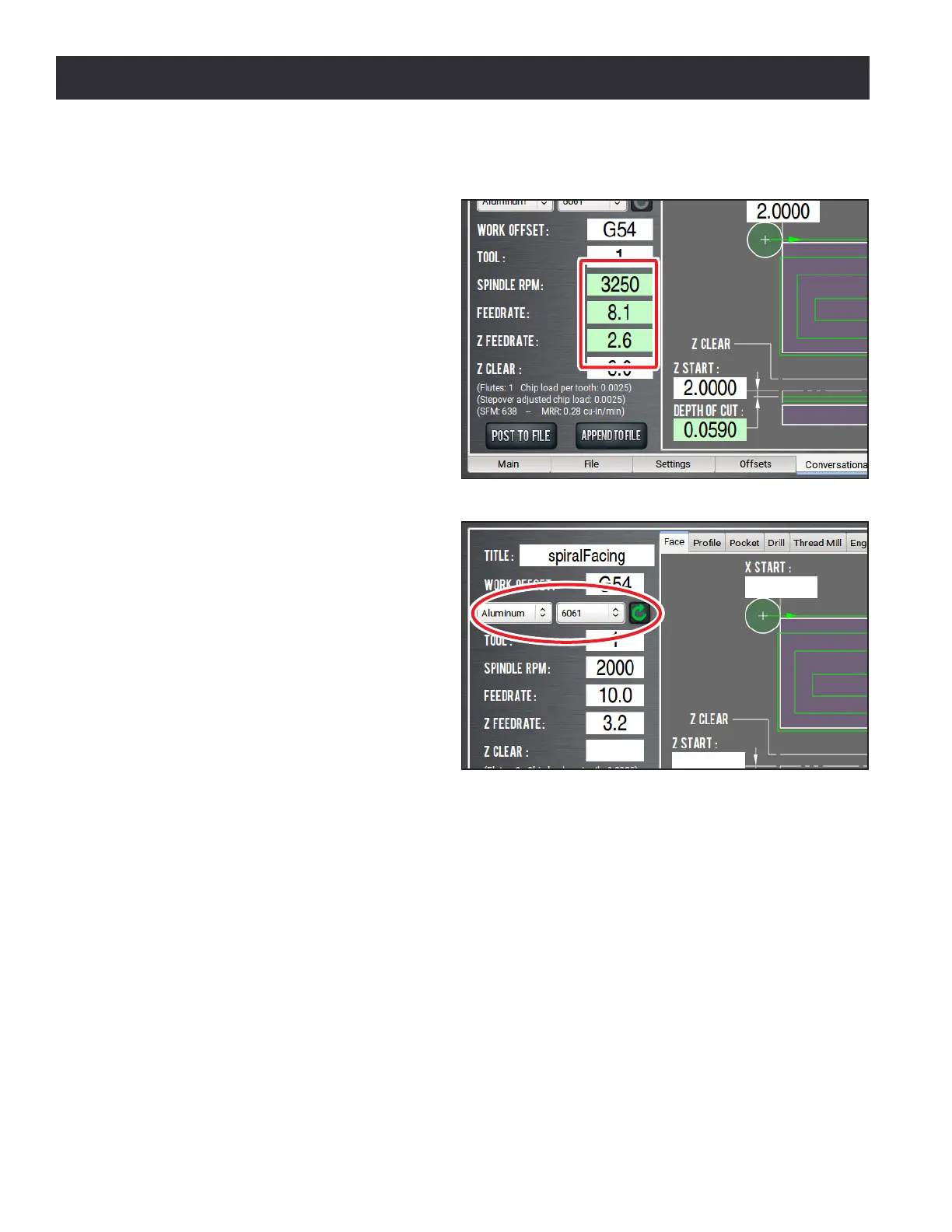

Aer selecng the material and tool, you

can adjust the values in the calculated

DROs, like Feedrate or Stepover. Adjusng

the value in one of these DROs does not

change the value in the other machining-

related DROs.

Once you adjust the value in the DRO, the

background switches from green back to

white (see Figure 6.24). This helps you

idenfy which DROs have suggested values

(those with a green background), and

which DROs have values you've supplied

(white background).

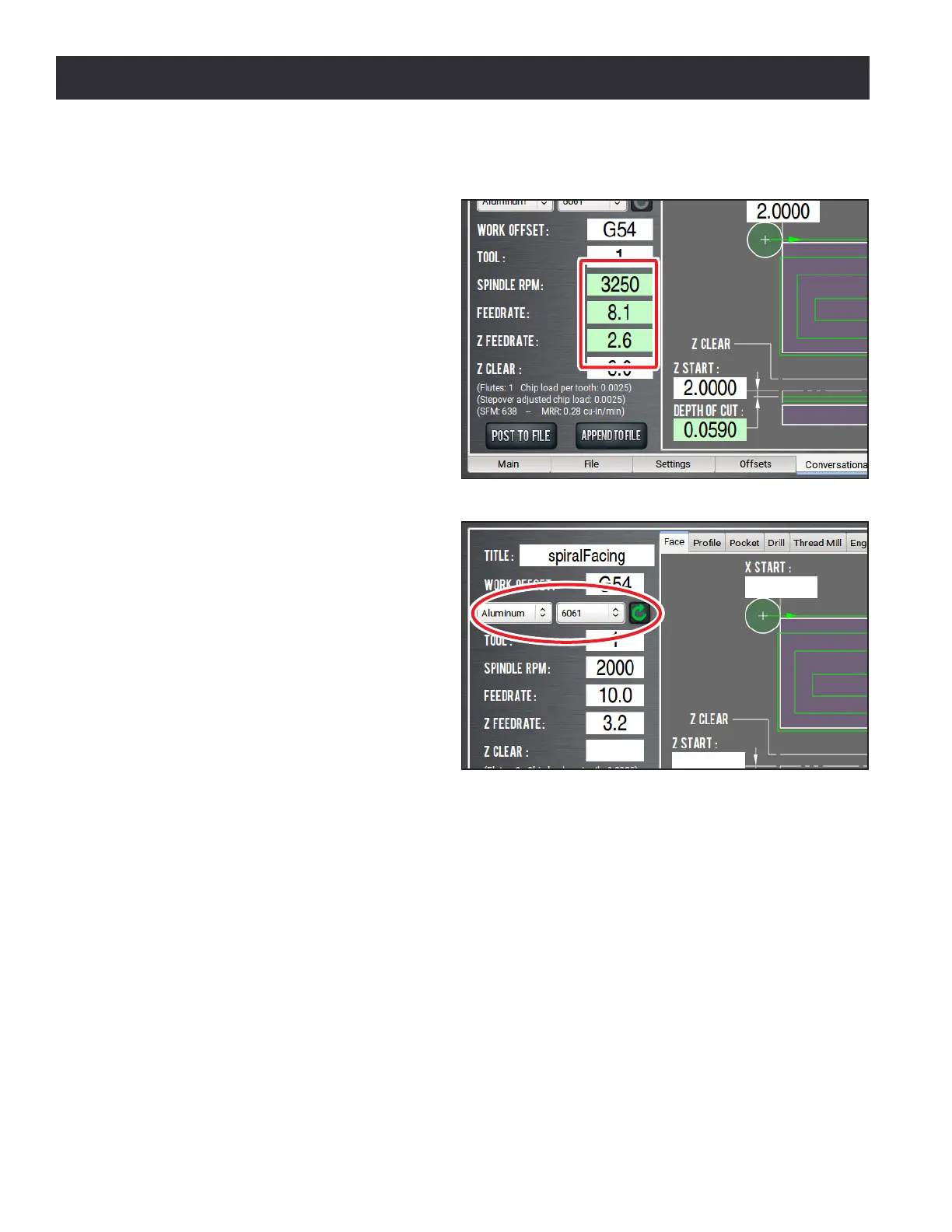

6.8.1.2 Resetting DRO Values

The suggested feeds and speeds are no

longer valid if:

• You select dierent material or sub-

type values, or if you type a new

value in to the Tool DRO.

The suggested feeds and speeds are

made by taking into account all of

these values. Changing any value

requires you to refresh.

• You select a dierent Conversaonal

tab.

The suggested feeds and speeds are made by taking into account the current, specic

conversaonal operaon — like Face, or Pocket. Changing your conversaonal operaon

requires you to refresh.

When the feeds and speeds are no longer valid, the Refresh buon turns green, and the machining-

related DRO backgrounds switch from green to white (see Figure 6.25).

6.8.1.3 Using Chip Load Information

On the Conversaonal tab, in the Conversaonal DROs group, there are ps that are displayed

based on the calculaons that PathPilot is performing (see Figure 6.26):

• Chip load informaon

Chip load — the amount of material removed per tooth — is based on the number of utes,

RPM, and feedrate.

Figure 6.24

Figure 6.25

Loading...

Loading...