Chapter 6

87

UM10372_PCNC440_Manual_0221A

PATHPilOT iNTERFACE

Start Angle – Species the angle from angle 0. Angle 0 is a base (horizontal) line from the

center point going right (east) to the circumference. The angle from the base line can be either

posive or negave, up to 90 degrees (or -90 degrees) and rotates the paern either clockwise

or counterclockwise. A negave angle produces a clockwise rotaon; a posive angle produces a

counterclockwise rotaon. For example, to create a hex paern with ats on the top and boom,

enter 0 into the Start Angle DRO. To create a hex paern with ats on the le and right sides, enter

30 (or -30) into the Start Angle DRO.

Diameter – The size of the circular paern as dened by a line through the center point of each hole.

Center X, Center Y – Denes the center point of the circular paern.

Spot Tool # – If this DRO contains a valid tool number when Post To File is clicked, a spot drilling

sequence using this tool number will occur prior to the drilling sequence. The Feedrate, Spindle

RPM, and Z Clear from the drilling sequence will be used for the spot drilling operaon. The depth

of cut for the spot drilling will be taken from the Spot Drill DOC DRO.

Spot Tool DOC – If the drilling operaon includes spot drilling, this DRO will be used to determine

the depth of cut for the spot drilling operaon (for more informaon on dening a tool for a spot

drilling operaon, refer to Spot Tool # earlier in this secon).

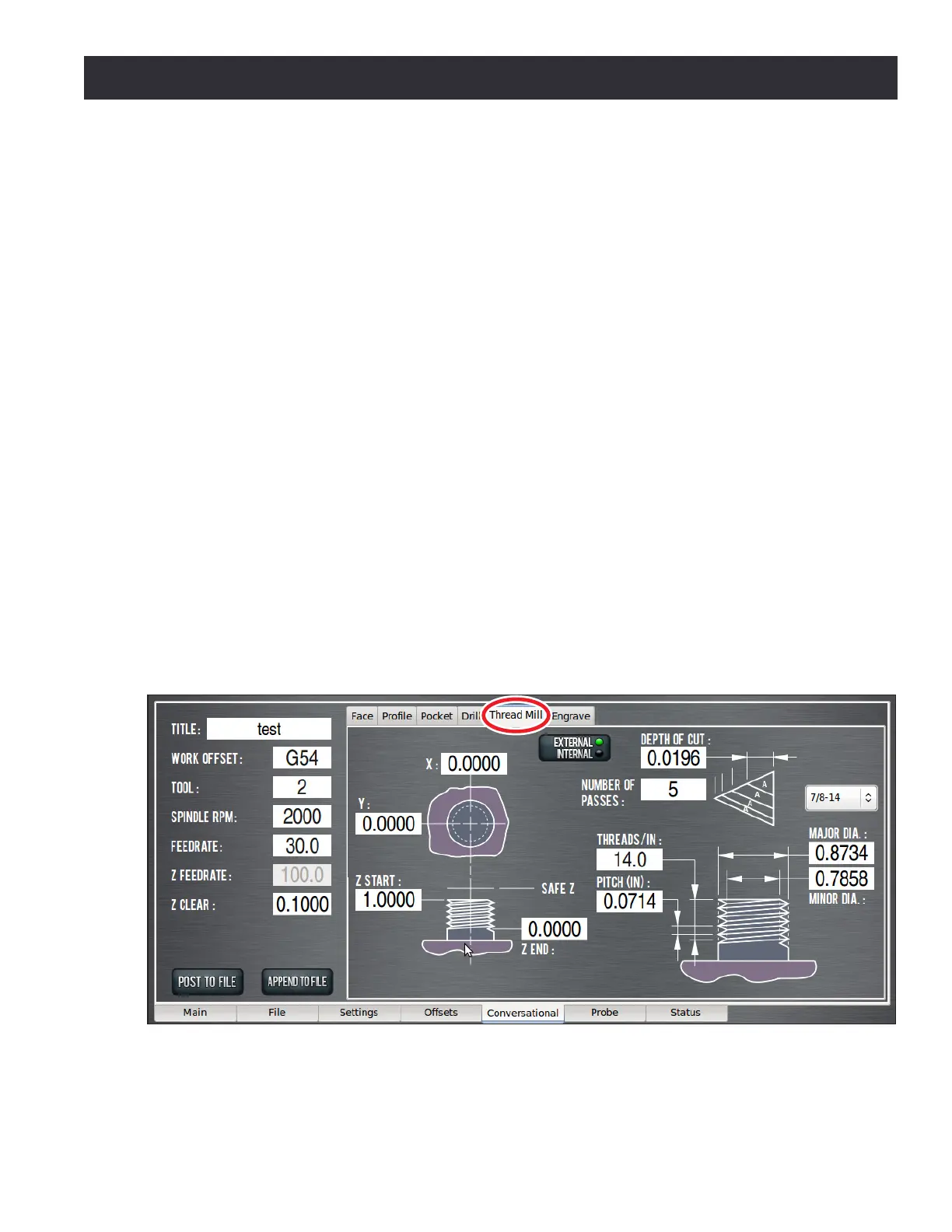

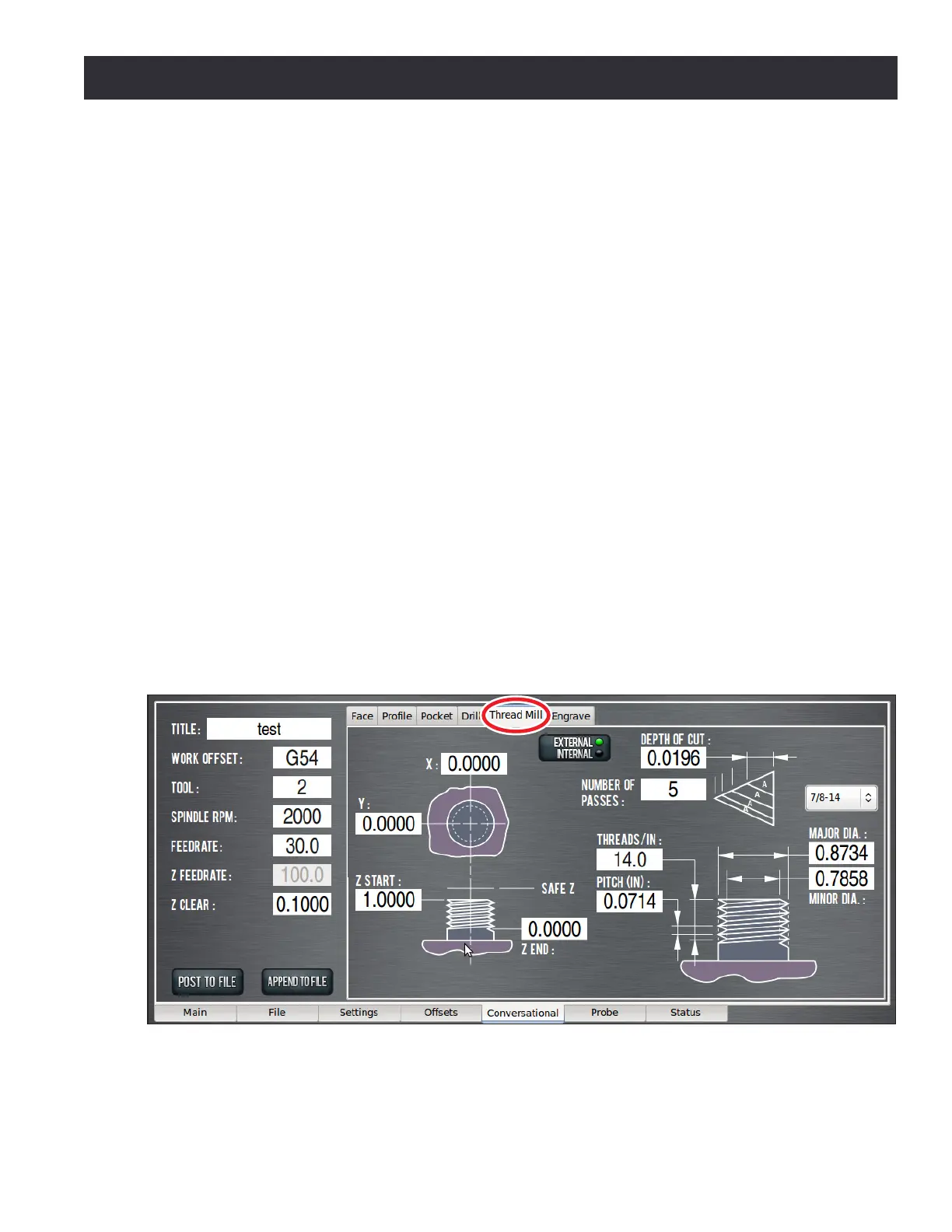

6.8.6 Thread Mill Tab

The thread milling roune produces helical tool paths needed for milling straight external or internal

right-handed threads based on pitch, diameter, and length (see Figure 6.34 and Figure 6.35).

Figure 6.34

Loading...

Loading...