Chapter 6

88

UM10372_PCNC440_Manual_0221A

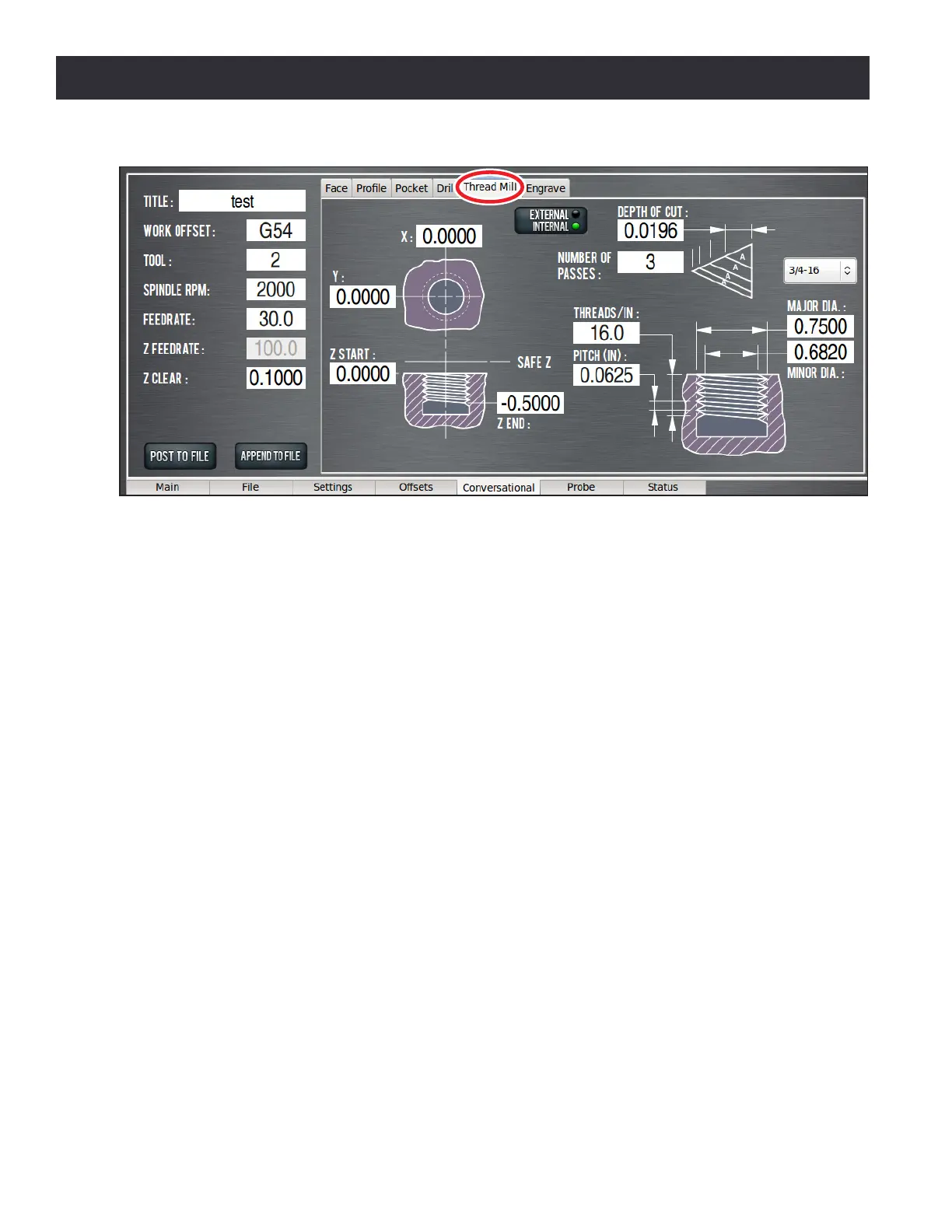

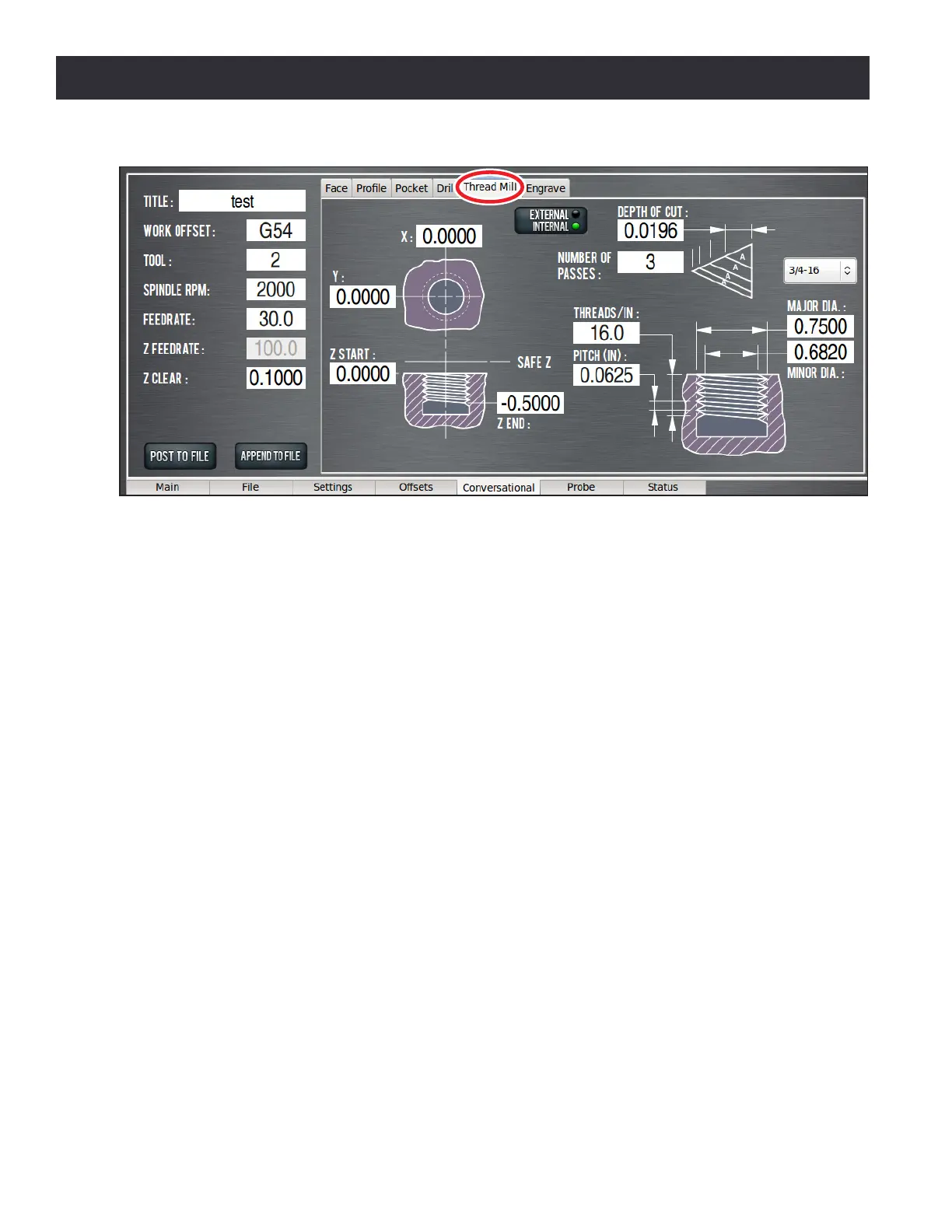

PATHPilOT iNTERFACE

Thread Table – Contains values for some common threads. The threads listed follow the current unit

seng (inch or millimeter). Once a selecon is made, the data from the selected thread is copied

to the appropriate DROs. This table is stored in user-editable text les found in the thread_data

subdirectory of the G-code folder on the controller's hard drive; to edit (e.g., to add to or modify

the defaults), highlight the le and click Edit G-code. For more informaon on les stored on the

controller's hard drive, refer to File Tab secon earlier in this chapter.

NOTE: The values entered in these tables assume a full form thread tool. If using a ne point threading

tool to cut coarse threads, the root diameter must be modied to account for the smaller tool nose radius

of the ne point threading tool.

XY DROs

X and Y – These DROs locate the center of the threaded stud or hole.

Major and Minor Diameter – Sets the start and end diameter of the thread peak and valley.

Depth of Cut – Sets the amount of material cut in each helical pass. The value entered is the distance

(change in radius) the tool is fed on the rst pass. This rst pass cuts a triangular area which is

related to the chip load. Subsequent cut depths are set to cut the same amount of area, so the linear

feed gets smaller for each pass. The tool is also fed in on a compound angle of 30°, keeping the cuts

to one face of the tool. The number of passes that t in a thread depth is calculated and presented

in the Number of Passes DRO.

Number of Passes – This DRO value is either calculated from the Depth of Cut value or can be

entered here, which invokes (upon pressing the Enter key) a calculaon and entry to the Depth of

Cut DRO.

Figure 6.35

Loading...

Loading...