Chapter 5

48

UM10372_PCNC440_Manual_0221A

iNTRO TO PATHPilOT

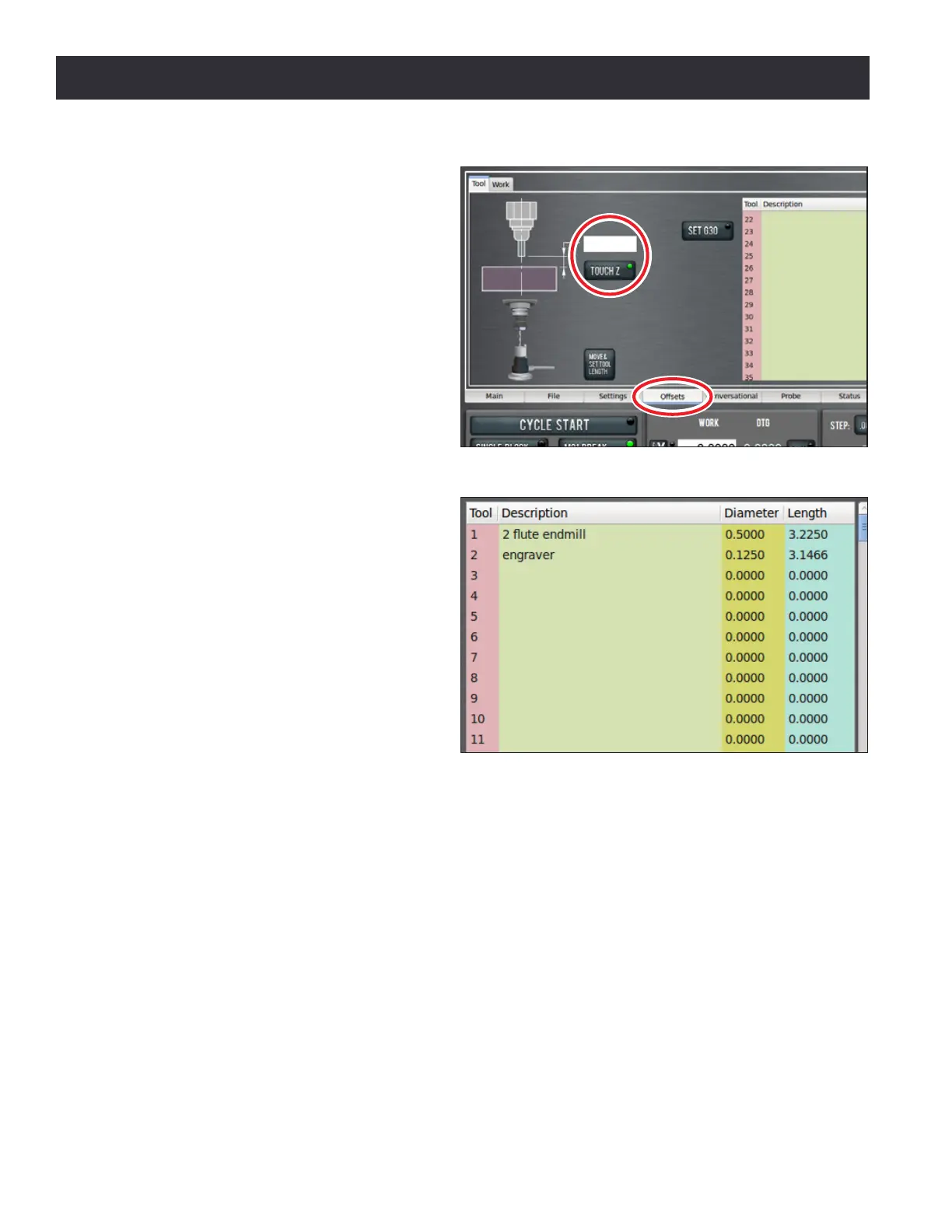

3. On the Osets tab, enter 0.0 in

the touch DRO and click the Touch

Z buon (see Figure 5.8). If you

were not touching on the top of

the workpiece, but instead using

a feeler gauge or piece of paper

between the workpiece and the

tool, you could enter the thickness

of the gauge or paper in the touch

DRO before clicking Touch Z to

account for the gauge thickness.

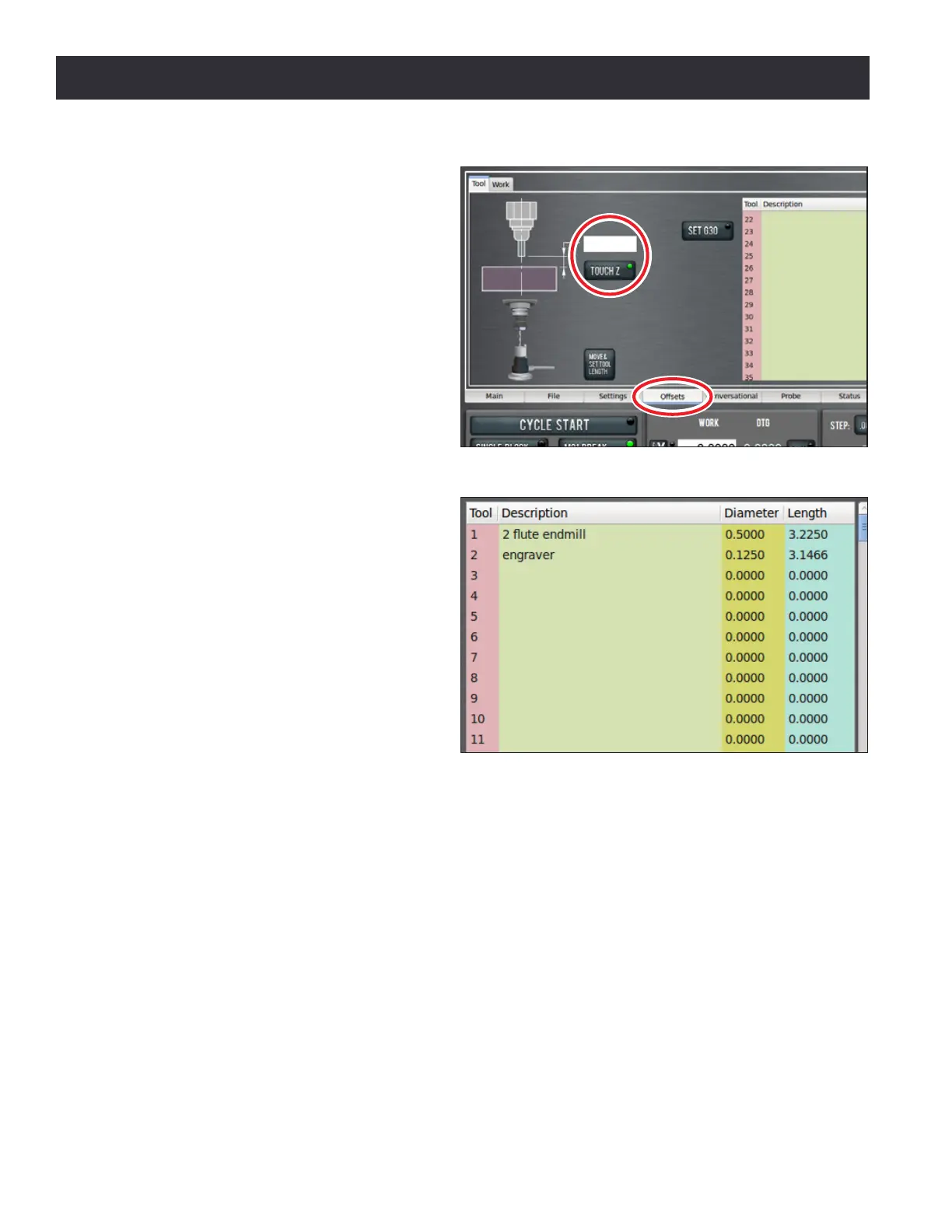

4. Look at the length value in the tool

table for Tool 1. Verify that it is

correct by measuring the length of

the tool from the spindle nose to

the tool p with a ruler or calipers.

5. Enter the diameter of the tool in the

tool table (see Figure 5.9) and press

Enter.

NOTE: Fracons entered in these entry elds are

converted to their decimal equivalents.

6. Put the 1/8” end mill tool holder

into the spindle.

7. Type 2 in the tool DRO and click the

M6 G43 buon (see Figure 5.5).

8. Repeat steps 3-6 to measure the

tool length for Tool 2.

5.1.8 Write the G-code

Now use Conversaonal programming capabilies of the PathPilot Interface to generate G-code to

produce our part (see Figure 5.1). This will be broken down into two operaons:

1. Mill a 0.100” deep, 3.25” diameter pocket in the face of the workpiece.

2. Engrave leers PCNC in the pocket.

Figure 5.8

Figure 5.9

Loading...

Loading...