Chapter 8

147

UM10350_PCNC770_Manual_0916A

Accessories

PN Description Tapping Head Type

32657 Tormach Reversing Tapping Head by Procunier Auto-Reversing

31807 Modular Tension/Compression TTS Tapping Head Kit Tension/Compression

32021 TTS ER20 Tapping Head Tension/Compression

32020 TTS ER16 Tapping Head Tension/Compression

NOTE: Tension compression heads can be programmed via G84 canned cycle.

For further informaon on tapping heads and general CNC tapping guidelines, refer to technical

document TD10077.

8.4 Oil And Coolant System Options

8.4.1 Automatic Oiler

The automac oiler has a 0.5 gallon reservoir with programmable stroke and interval. An audible

warning alerts the operator when oil level is low. Available models include:

PN Description

31374 Automatic Oiler Kit for PCNC 1100 – 230 VAC

31373 Automatic Oiler Kit for PCNC 770 – 115 VAC

8.4.2 Spray Coolant

The Fog Buster Spray Coolant Kit is a non-fogging, non-atomizing, low-pressure sprayer with a

115 VAC solenoid valve included to integrate via M7/M8/M9 program commands. Requires 90 psi

air supply.

PN Description

32682 Fog Buster Spray Coolant Kit

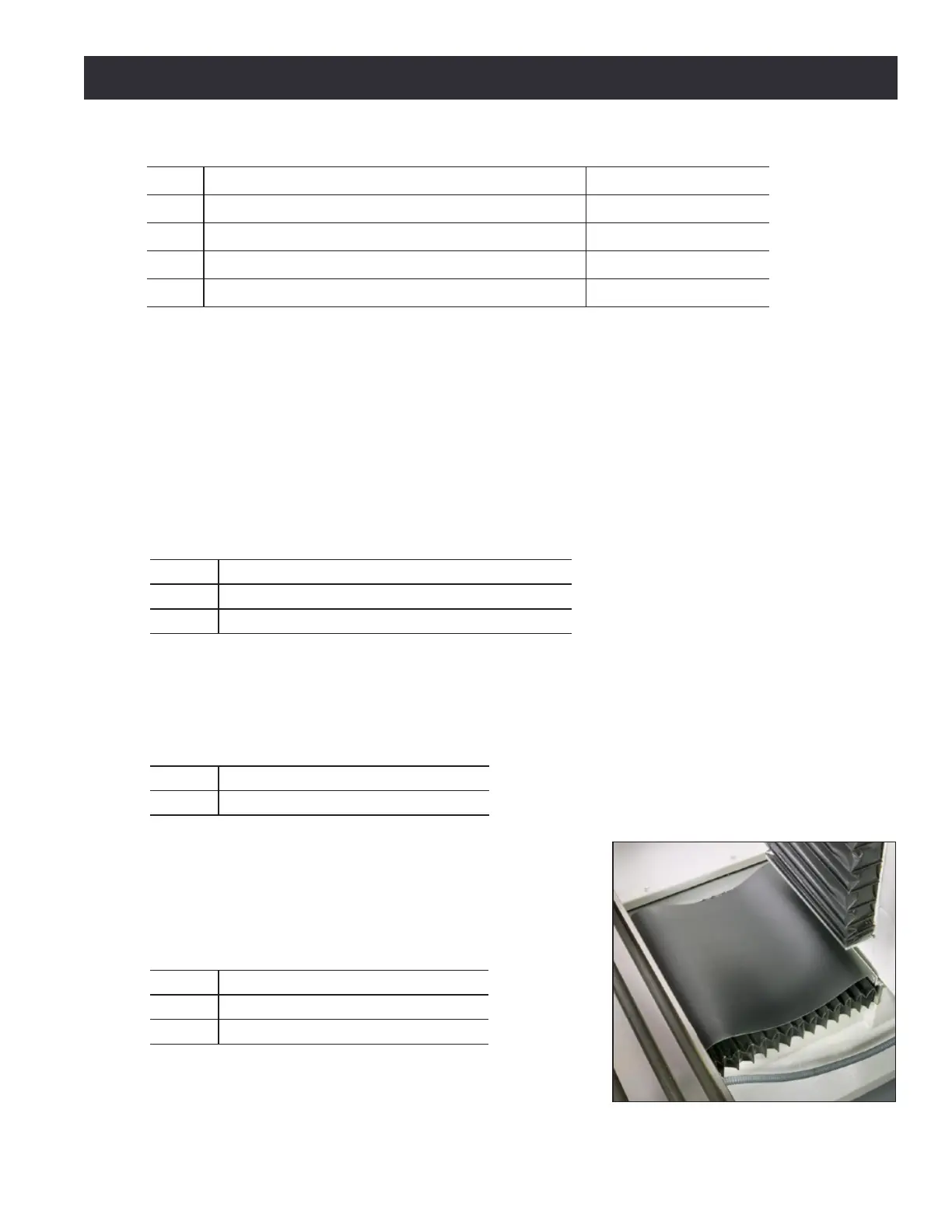

8.4.3 Chip Flap Kit

These heavy-gauge, rubber-chip aps

provide extra protecon for way

covers from premature wear caused by

abrasive metal chips (see Figure 8.7).

PN Description

32780 Y-axis Chip Flap; PCNC 1100

32807 Y-axis Chip Flap; PCNC 770

Figure 8.7

Loading...

Loading...