Chapter 3

27

UM10350_PCNC770_Manual_0916A

Installation

7. Ensure coupling is centrally posioned between motor sha and machined end of Ball Screw;

ghten cap screws on coupling.

8. Tighten cap screws holding motor to motor mount securely.

3.3.5 Lift and Move Mill

WARNING! Transport and Li Hazard: The transport, liing, and moving of PCNC mill should be

done by qualied professionals. Failure to do so may result in mill damage, serious injury or death.

3.3.5.1 Remove Mill from Pallet

The mill is secured to the shipping pallet with four bolts. Before aempng to li mill, use wrench to

remove nuts holding mill to pallet. This allows mill to be separated from shipping pallet when liing.

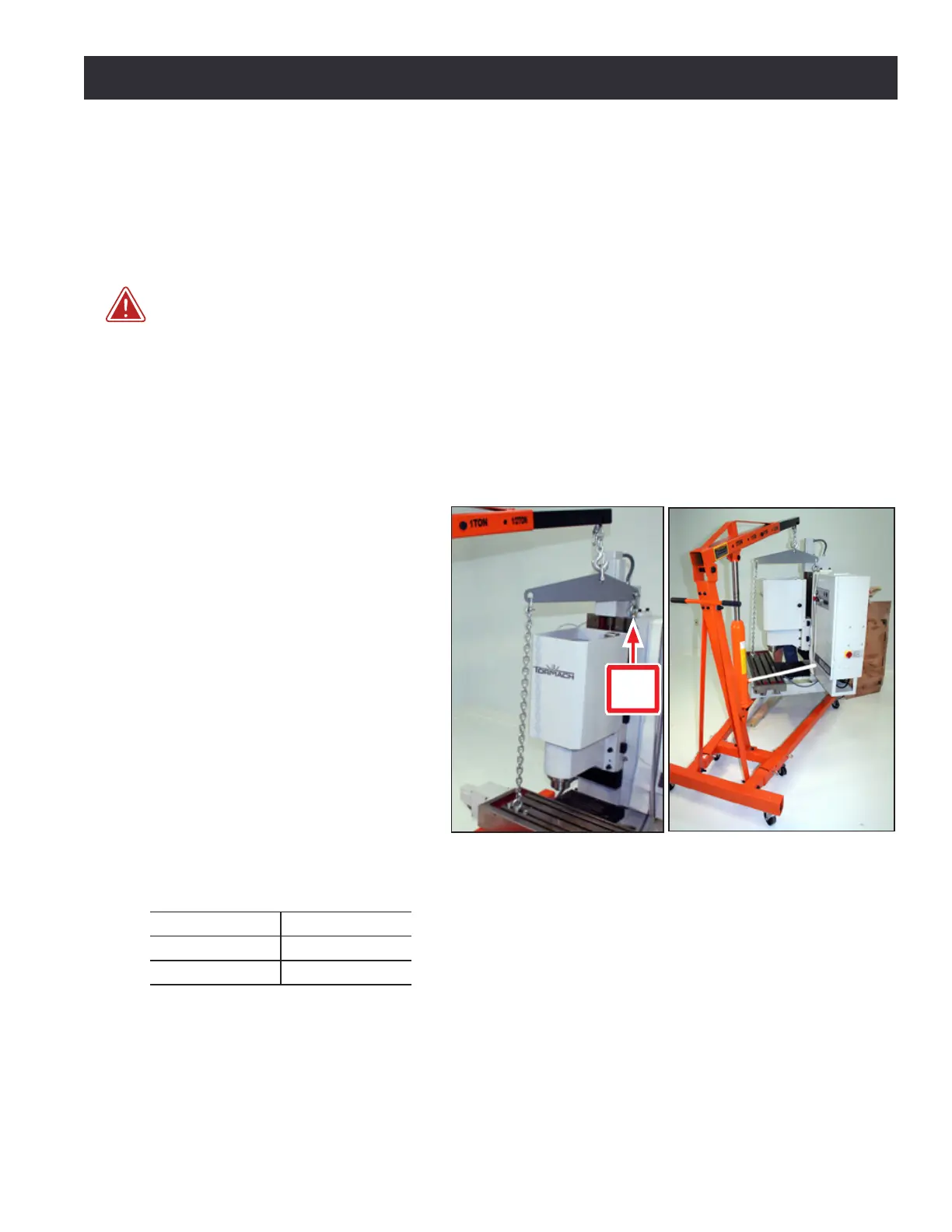

3.3.5.2 Lifting Bar Kit

The preferred method for liing the

mill is from above, using the Liing

Bar Kit (PN 31446), as shown in Figure

3.5; use this method with either a

forkli or engine hoist. The single

Eye Bolt on the top of the column is

suitable for liing the enre weight

of the mill. However, it is recommend

that the Liing Bar Kit be used (see

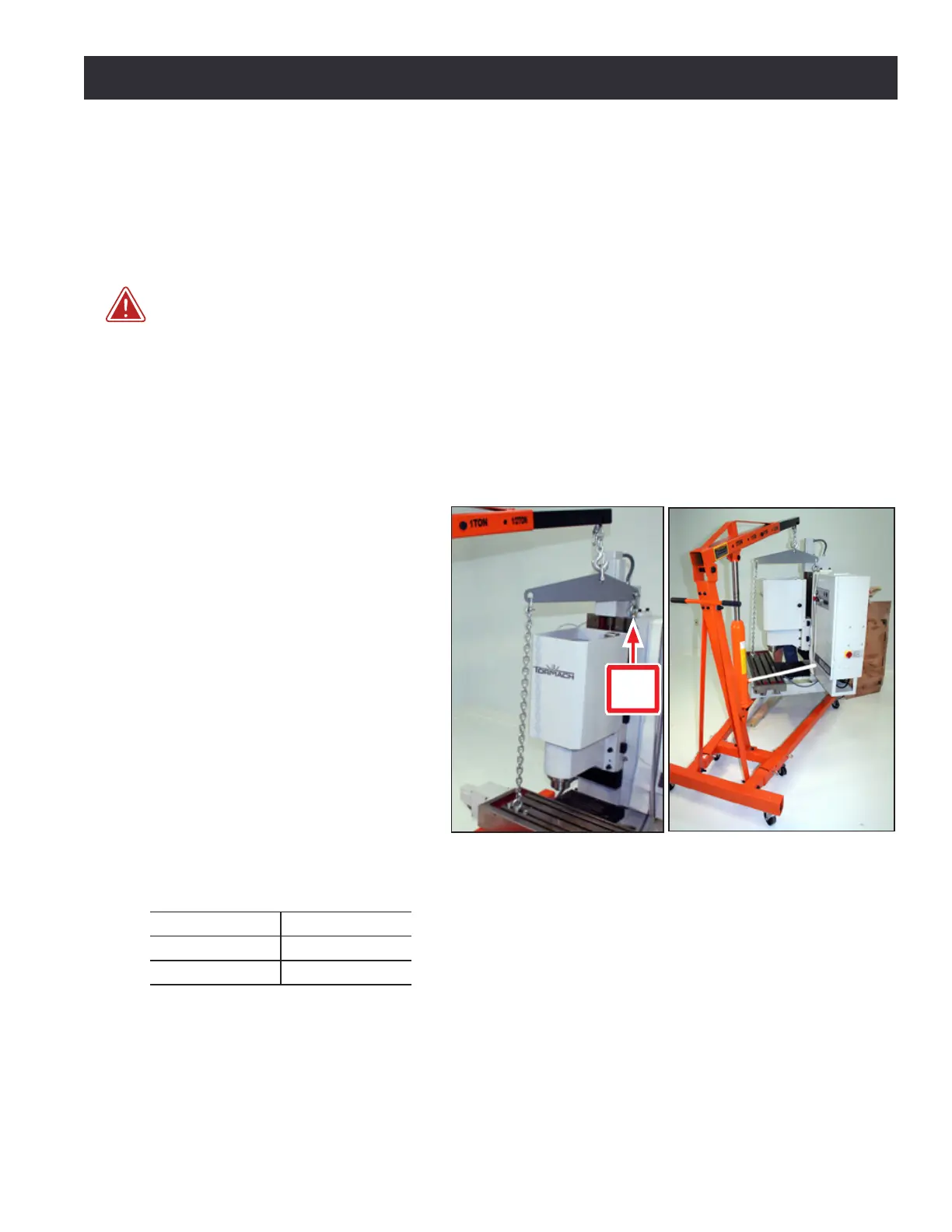

Figure 3.5 and Figure 3.6). Refer to

documentaon that ships with Liing

Bar Kit for more informaon on use.

Do not aempt to li mill from above

using any other method. If using an

engine hoist, refer to the following

table to determine the minimum

distance necessary to straddle stand

between hoist legs.

Machine Measurement

PCNC 1100 37”

PCNC 770 29”

3.3.5.3 Lifting from Below

It is also possible to li the mill from below by inserng steel bars into two sets of opposing 7/8”

diameter holes located in the machine base. The bars must be a minimum of 32” in length and

should be made of solid steel. Do not use hollow pipe to li mill.

Figure 3.5

Figure 3.6

Eye

Bolt

Loading...

Loading...