Chapter 7

97

UM10350_PCNC770_Manual_0916A

Programming

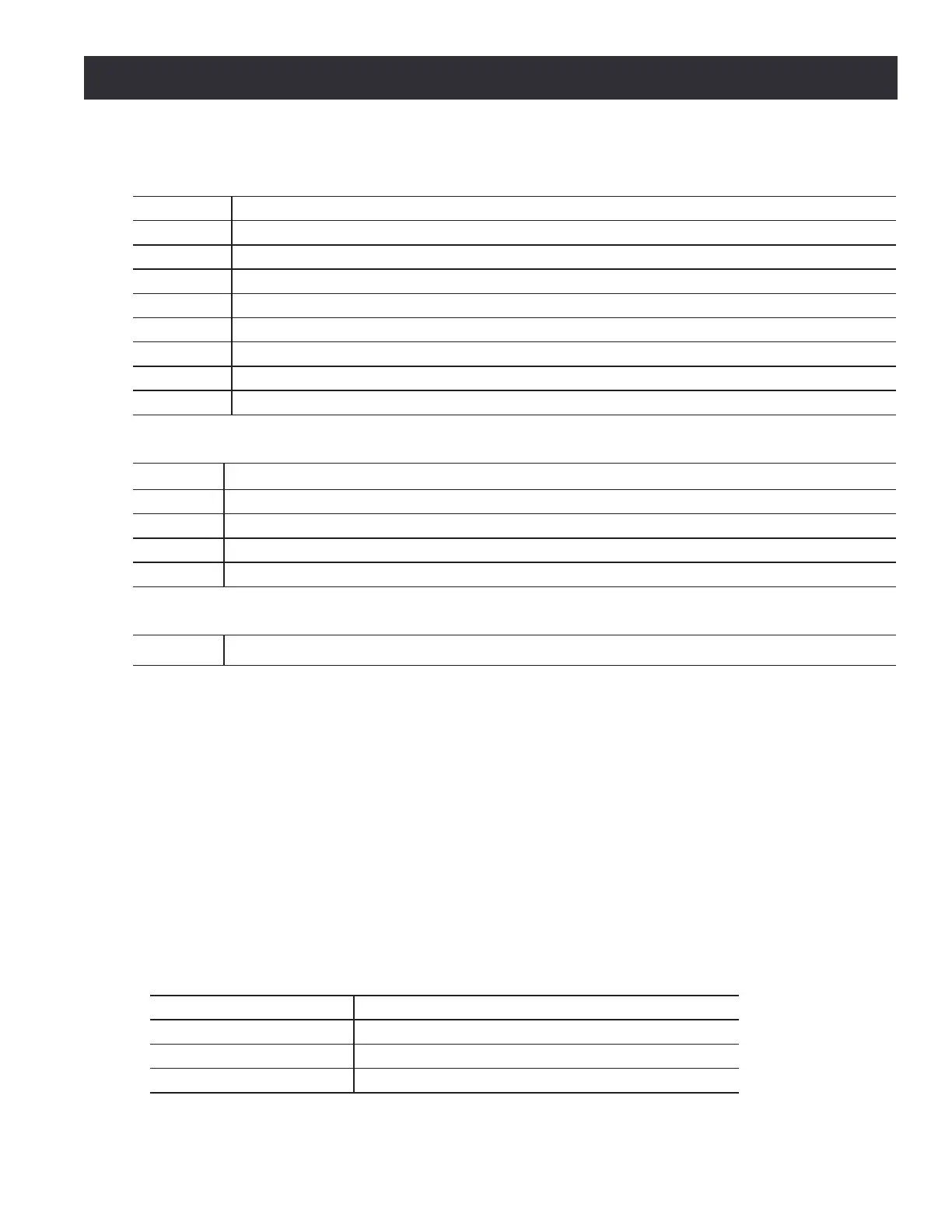

Modal Groups for G-codes

Group 5 = {G93, G94} feed rate mode

Group 6 = {G20, G21} units

Group 7 = {G40, G41, G42, G41.1, G42.1} cutter radius compensation

Group 8 = {G43, G43.1, G49} tool length offset

Group 10 = {G98, G99} return mode in canned cycles

Group 12 = {G54, G55, G56, G57, G58, G59, G59.1, G59.2, G59.3} coordinate system selection

Group 13 = {G61, G61.1, G64} path control mode

Group 14 = {G96, G97} spindle speed mode

Group 15 = {G07, G08} lathe diameter mode

Modal Groups for M-codes

Group 4 = {M00, M01, M02, M30, M60} stopping

Group 7 = {M03, M04, M05} spindle turning

Group 8 = {M07, M08, M09} coolant (special case: M07 and M08 may be active at the same time)

Group 9 = {M48, M49} enable/disable feed and speed override controls

Group 10 =

{operator dened M100 to M199}

Non-modal G-codes

Group 0 = {G04, G10, G28, G30, G53, G92, G92.1, G92.2, G92.3}

7.4.6 Default Modes

For all G-code modal groups, when a machining system is ready to accept commands, one member

of the modal group must be in eect. There are default sengs for these modal groups. When the

machining system is turned on or re-inialized, default values are automacally in eect.

Group 1, the rst group on the table is a group of G-codes for moon. One of these is always in

eect. That one is called the current moon mode.

7.5 G-codes

The supported G-codes are shown and described in more detail in this secon. The descripons

contain command examples set in Courier type font.

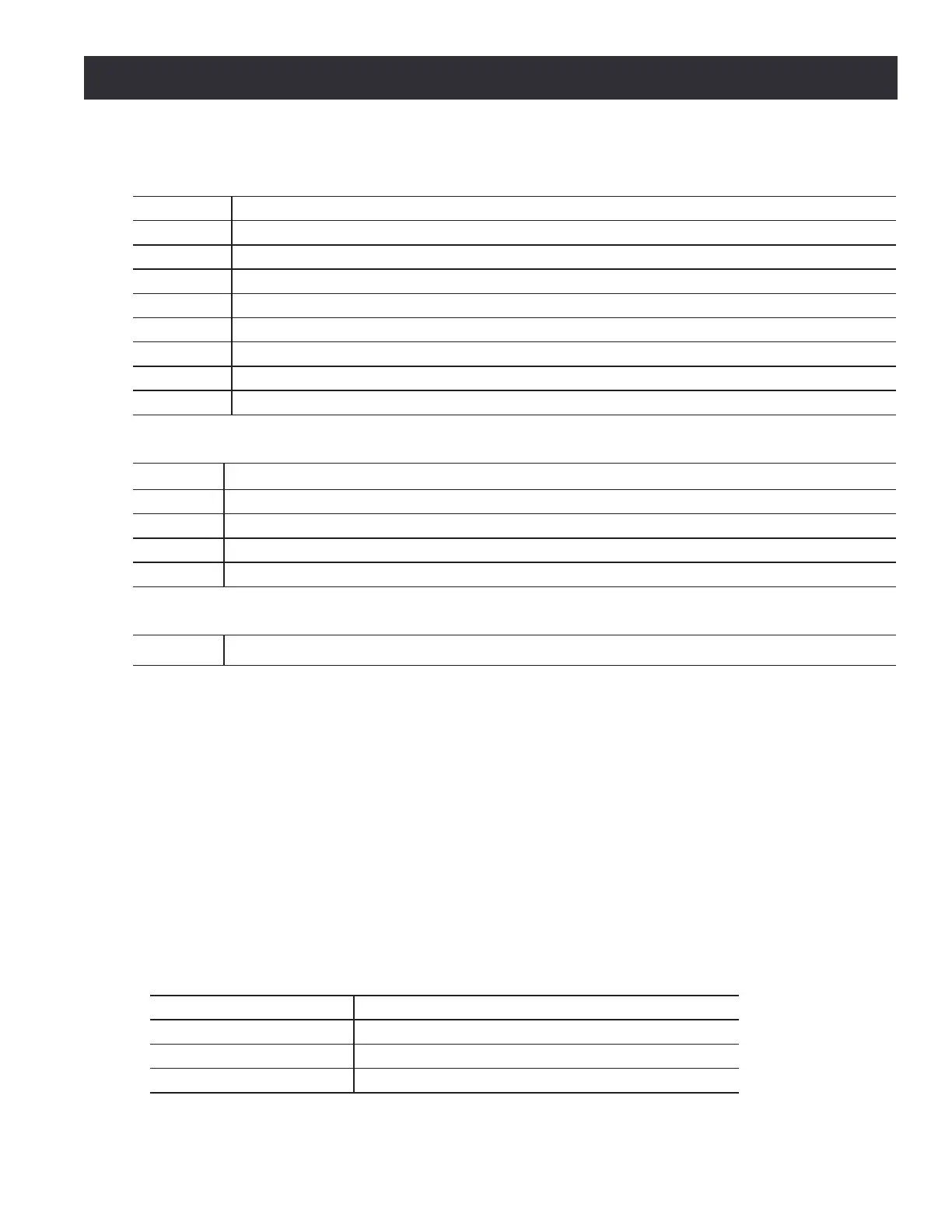

Summary of G-codes

G00 Rapid positioning

G01 Linear interpolation

G02 Clockwise circular interpolation

G03 Counter-clockwise circular interpolation

(connued on next page...)

(...continued)

Loading...

Loading...