Chapter 6

56

UM10350_PCNC770_Manual_0916A

PathPilot Interface

• Clears alarms (for more informaon on alarms, see the Status tab secon)

• Clears the tool path backplot

Spindle Override – The Spindle Override Slider and RPM 100% buon (see Figure 6.2) allow you to

override the commanded spindle speed by percentages ranging from 1 percent to 150 percent. The

RPM 100% buon returns the override to 100 percent of the commanded value or no override. The

spindle must be running for these controls to have a noceable eect. If overriden when the spindle

is stopped, the speed is overridden the next me spindle starts. The override doesn’t drive the

spindle past its maximum speed. The Spindle Override seng is ignored during spindle-synchronized

(e.g., G84 tapping cycle) moves or any me M48 (disable feed and speed overrides) is in eect.

Feedrate Override – The Feedrate Override Slider and Feed 100% buon (see Figure 6.2) work

similarly to the spindle override controls. They aect the commanded feedrate by a percentage

ranging from 1 percent to 150 percent. The feedrate override works for MDI, jogging, and G-code

program G01/G02/G03 moves. The override has no eect on G00 (rapid) moves. The Feedrate

Override seng is ignored during spindle-synchronized (e.g. G84 tapping cycle) moves or any me

M48 (disable feed and speed overrides) is in eect.

Maxvel Override – The Maxvel Override and Maxvel 100% buon (see Figure 6.2) work similarly

to the Feedrate Override controls, except that these controls aect both G00 and G01 moves. They

clamp the mill velocity to a percentage of the maximum velocity. The Maxvel slider can be very

useful when running a G-code program for the rst me. You can use it to stop the mill by sliding

it down to 0 percent and verifying the Distance to Go and X/Y/Z/A DROs look appropriate before

connuing. The Maxvel Override is a safety feature, and as such is not inhibited during spindle-

synchronized moves or with M48. Make sure that Maxvel is at a value that allows the mill to achieve

the programmed feed rate during spindle synchronized moves (e.g. G84 tapping) or the move may

fail to produce the intended results.

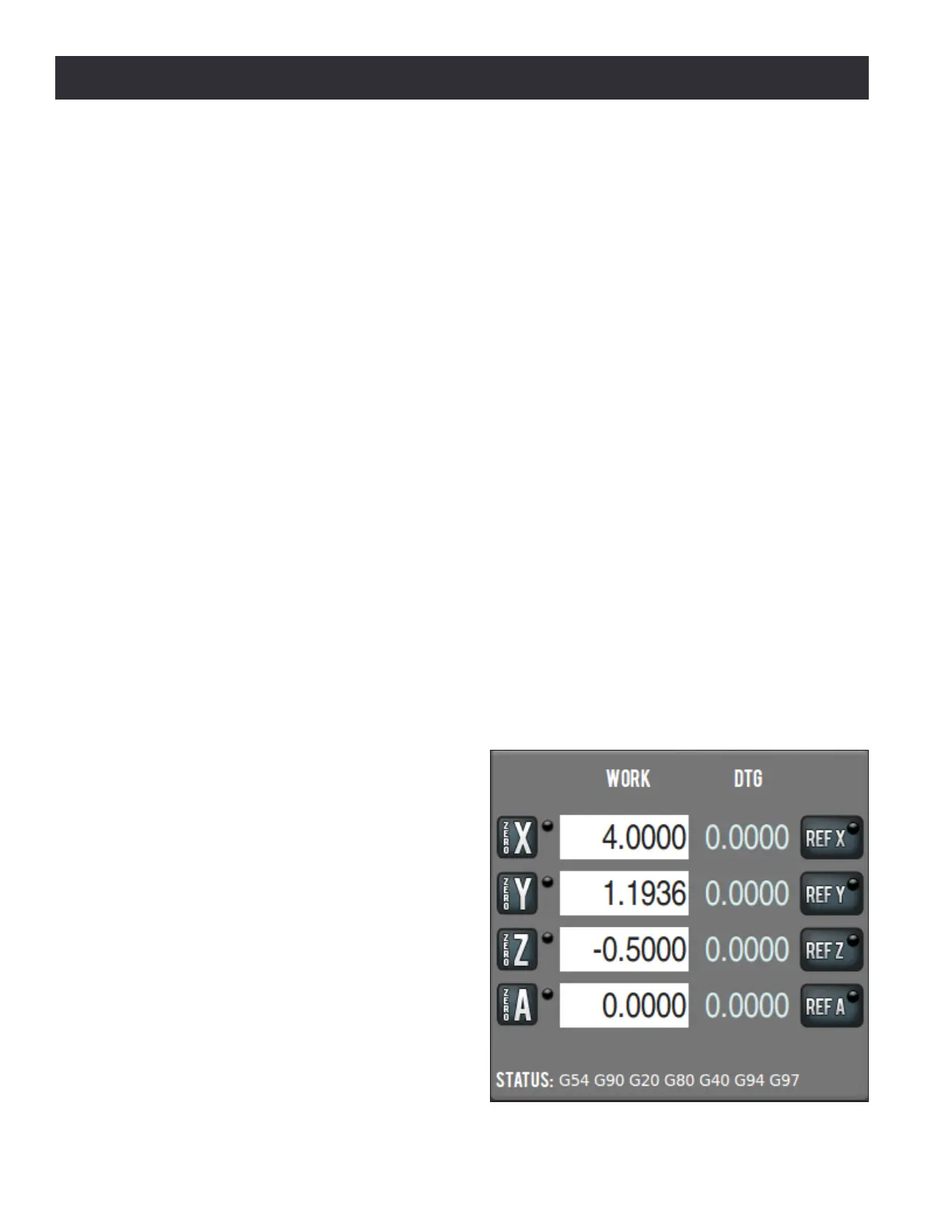

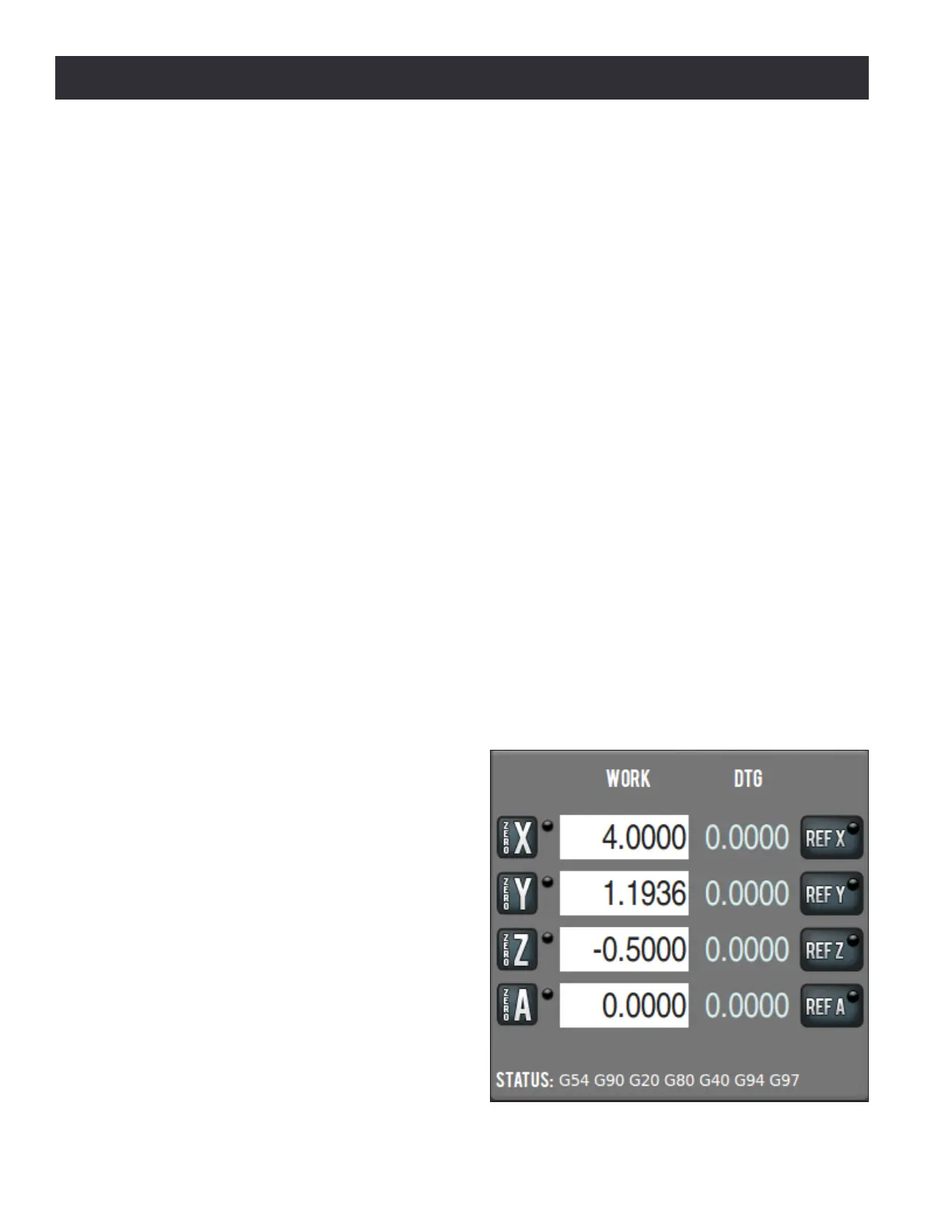

6.2.2 Position Status Group

The buons, labels, and DROs of the Posion

Status Group pertain to mill posion, acve

G-code modalies, and feed/speed sengs

(see Figure 6.3). These controls may be used

at any me before or aer running a G-code

program or MDI move. They are unavailable

for operator input while mill is moving.

Axes Work Oset DROs – The X, Y, Z, and A

work oset DROs display the current mill

posion expressed in the currently acve work

oset coordinate system (G54, G55, etc.).

Figure 6.3

Loading...

Loading...