Chapter 9

165

UM10350_PCNC770_Manual_0916A

Maintenance

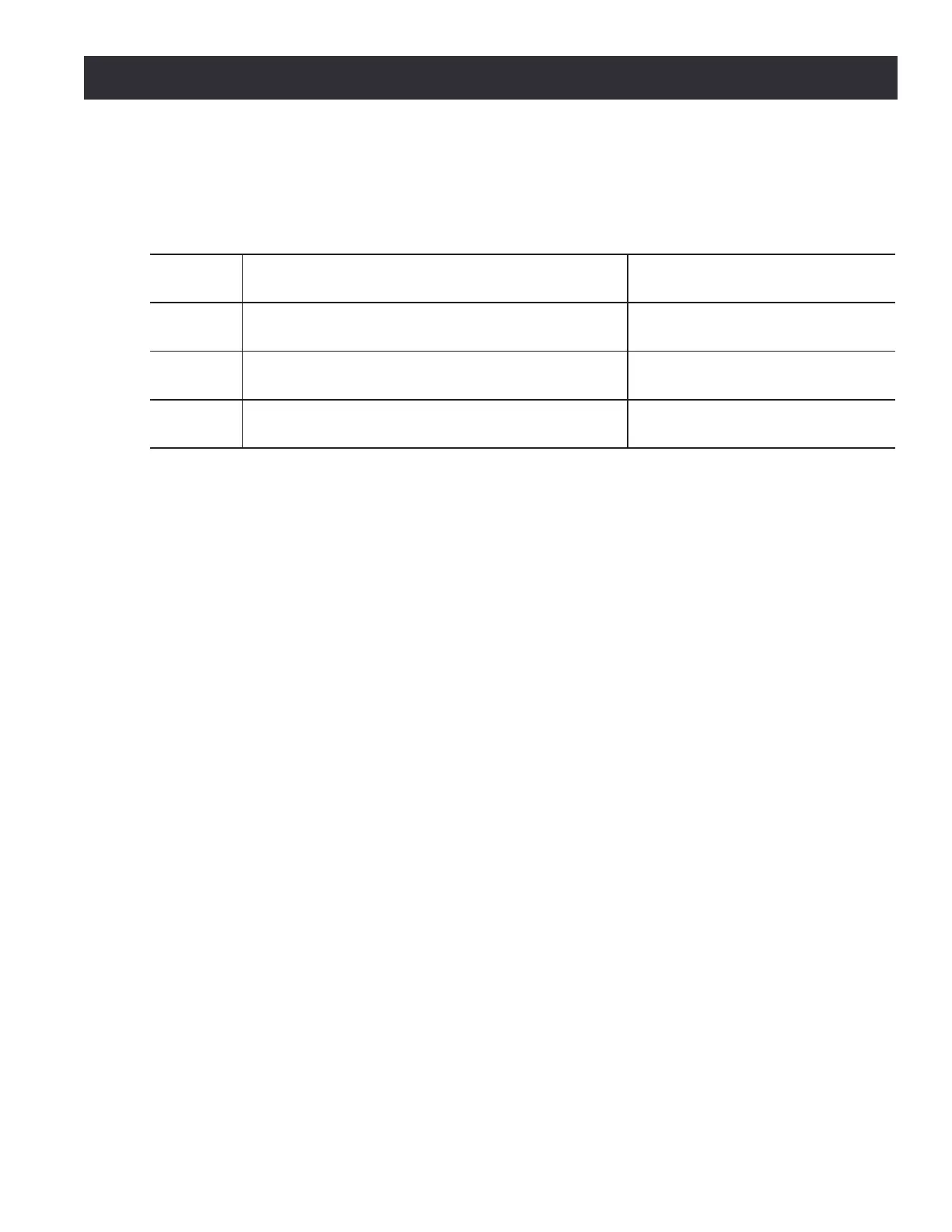

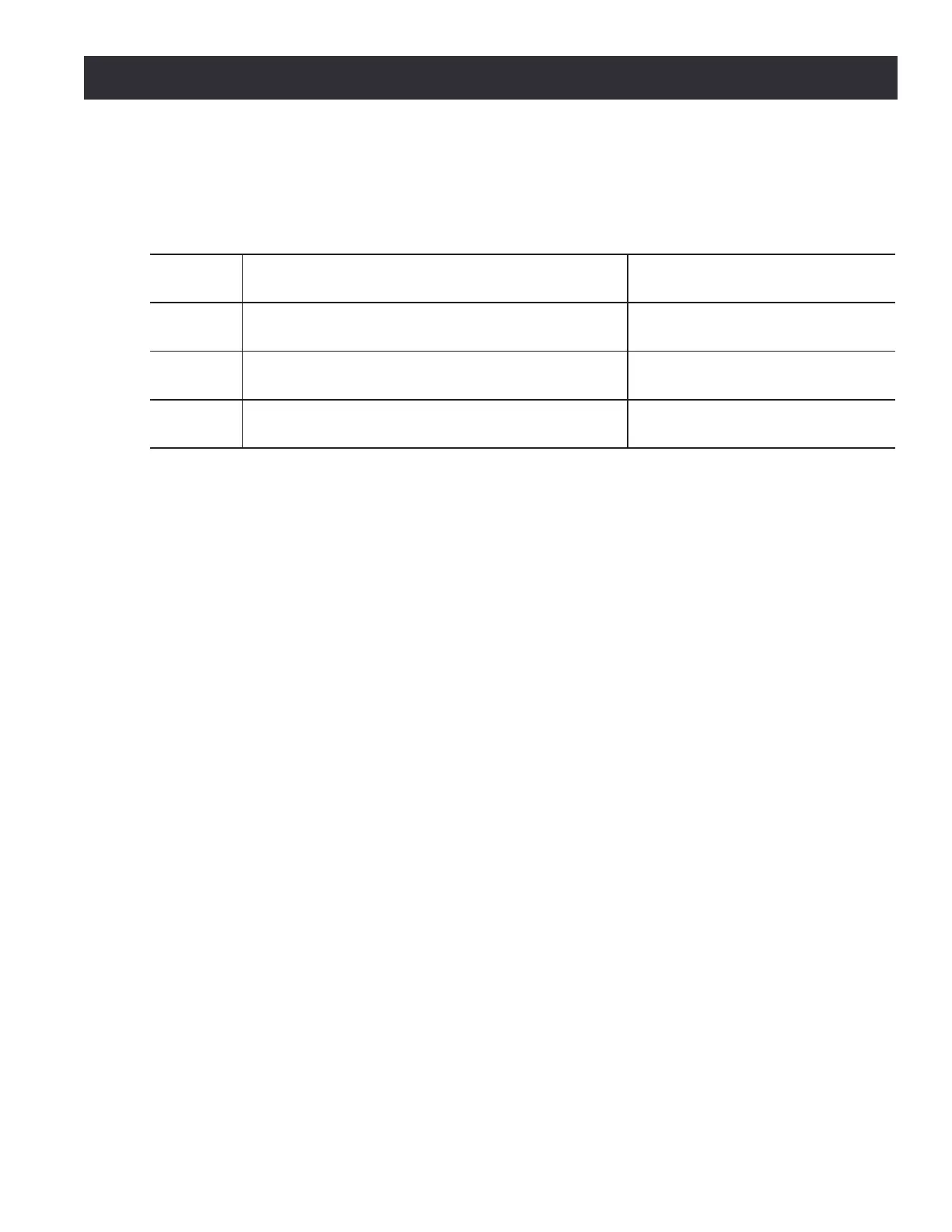

9.3.3.2 Adjustment Procedure

The gib ghtening adjustment procedure for each linear axis is detailed in the table below.

Gib Plate Tighten

1

Notes

X-axis

(PCNC 1100)

Left screw clockwise/right screw counterclockwise

No cover removal required

X-axis

(PCNC 770)

Left screw counterclockwise/right screw clockwise No cover removal required

Y-axis Front screw clockwise/rear screw counterclockwise

Remove front and rear way covers to

access gib screws

Z-axis Upper screw clockwise/lower screw counterclockwise

Support spindle head with wooden

block on table

1

To loosen, reverse rotation direction indicated in table.

NOTE: It is dicult to assess the correct clearance for the gib, as a very small adjustment can create a

dramac change in sliding con.

The recommended method for gib adjustment is to measure axis lost moon while incrementally

ghtening the gibs to arrive at the correct seng. The following procedure describes this method

for the Z-axis. A similar procure can be used to adjust the X-axis and Y-axis gibs; however, it should

be noted that the X- and Y-axis gib adjustments cannot be considered in isolaon. Tightening or

loosening a gib on either axis also has an eect on the opposing axis.

1. Loosen the upper gib screw eight rotaons and ghten the lower gib screw eight rotaons.

This ensures that the gib clearance is quite loose.

2. Use a dial indicator to measure lost moon in the Z-axis (refer to How to Measure Lost Axis

Moon earlier in this chapter). With a very loose gib, the majority of the measured lost moon

is aributable to the backlash in the angular contact bearing pair. On a new mill, this value

measured should be less than 0.0015” on the Z-axis and less than .0013” on X- and Y-axis.

3. Tighten the gib by one turn by loosening the lower screw rst, then ghtening the upper

screw. Measure the backlash again.

4. Repeat this procedure unl the measured backlash begins to increase. At this point, the gib

seng is slightly too ght.

Loading...

Loading...