Chapter 5

49

UM10350_PCNC770_Manual_0916A

Intro to PathPilot

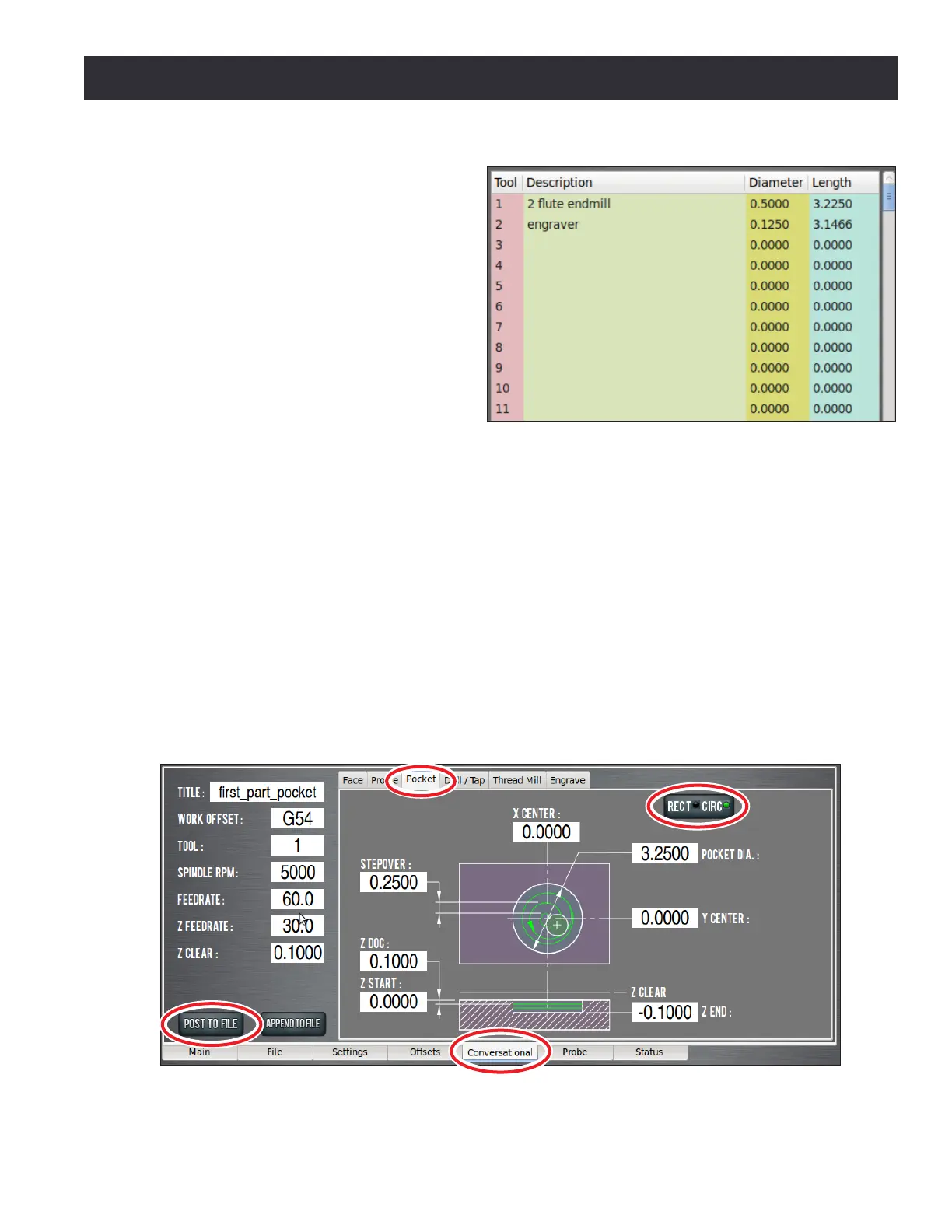

Figure 5.9

7. Type 2 in the tool DRO and click the

M6 G43 buon (see Figure 5.5).

8. Repeat steps 3-6 to measure the

tool length for Tool 2.

5.1.5 Writing the G-code

Now use Conversaonal programming

capabilies of the PathPilot interface to

generate G-code to produce our part (see

Figure 5.1). This will be broken down into

two operaons:

1. Mill a 0.100” deep, 3.25” diameter

pocket in the face of the workpiece.

2. Engrave the leers PCNC in the pocket.

5.1.5.1 Operation 1

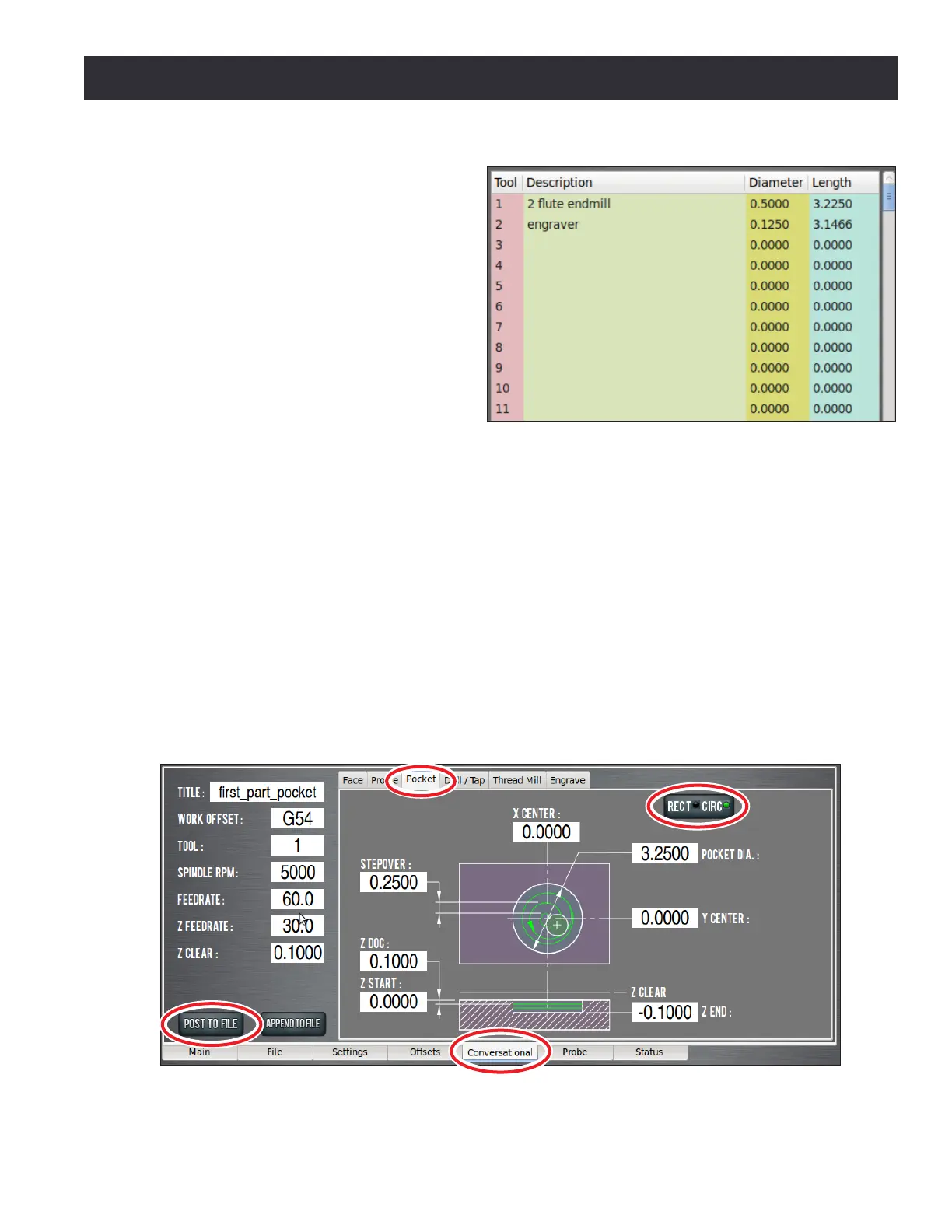

To write code for the rst operaon, click the Conversaonal tab (see Figure 5.10). The Conversaonal

screen is divided into two secons: parameters common to most operaons are displayed on the

le and operaon-specic parameters (including part geometry) are displayed on the right.

Click the Pocket tab to bring up the pockeng screen. Click the Rect/CircI buon to bring up the

circular pocket screen (see Figure 5.10). Use this screen to generate code to create a shallow pocket

(0.1000” deep and 3.250” in diameter). The conversaonal DRO elds should be self-explanatory

and are covered in detail in chapter 6, PathPilot Interface, but for now, enter the values seen in

Figure 5.10.

Figure 5.10

Loading...

Loading...