Chapter 3

26

UM10350_PCNC770_Manual_0916A

Installation

3.3.2 Remove Tool Tray (PCNC 1100 only)

Carefully remove the Tool Tray from the pallet and set aside for installaon later (see Figure 3.7).

3.3.3 Remove Accessory Tool Box

A wooden Tool Box is nailed to the pallet (see Figure 3.2). This box contains tools that are required

for installaon. Carefully remove box from pallet using pry bar.

NOTE: The Spindle Lockout Key – used to lock or unlock the spindle – is located in the Tool Box. The spindle

with not rotate without the key inserted in the Operator Panel locaon shown in Figure 3.13.

3.3.4 Assembling Y-Axis (PCNC 1100 only)

The PCNC 1100 is supplied with the Y-axis

Motor mechanically disconnected; install

it before aempng to remove mill from

pallet (see Figures 3.3 and 3.4).

IMPORTANT! Damage to mill may occur if Y-axis

Motor weight is supported by motor wires.

1. Unstrap Y-axis Motor from pallet

(see Figure 3.3).

2. Remove Y-axis Motor Mount Cover

Plate from Y-axis Motor Mount (see

Figure 3.3).

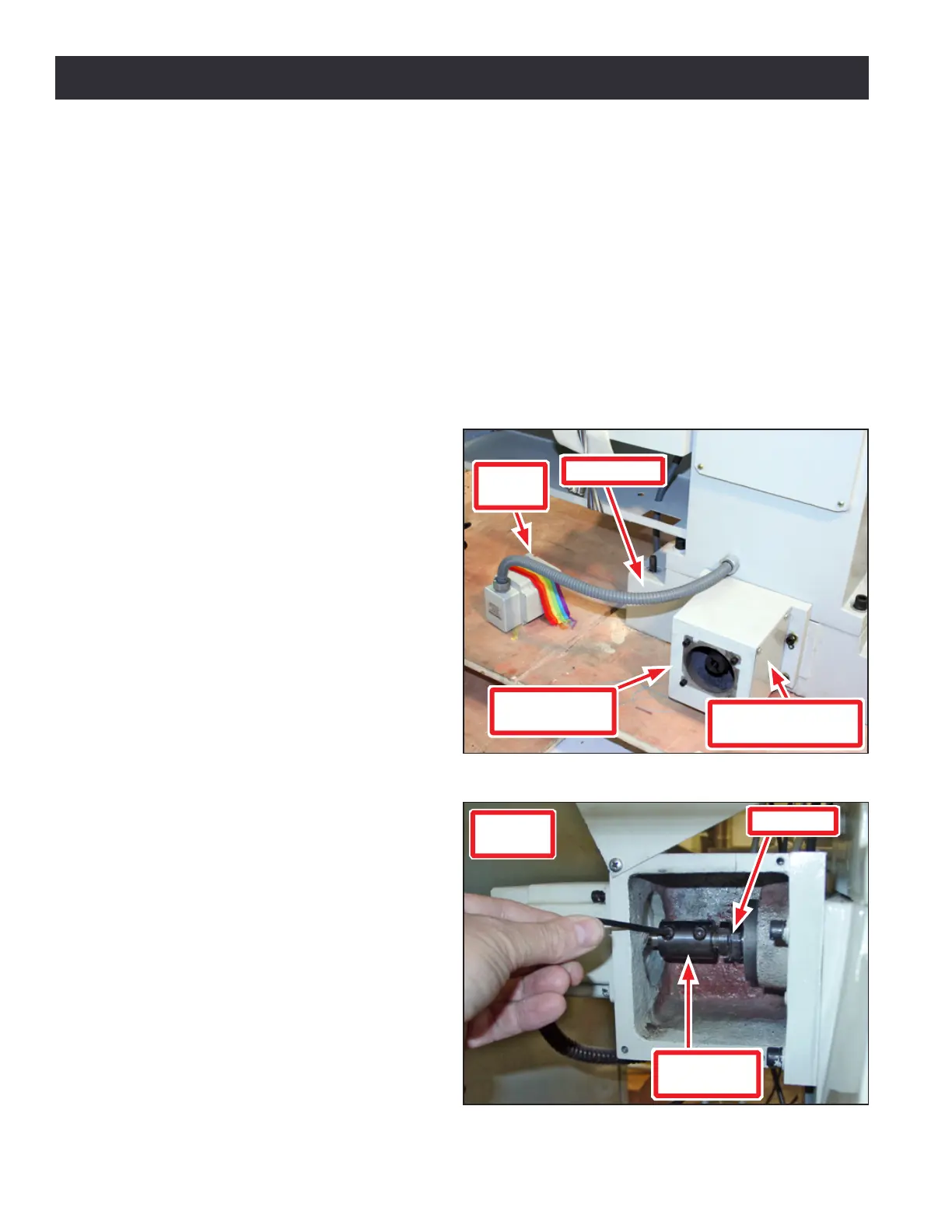

3. Using 4 mm hex wrench (included),

loosen two Motor Sha Coupling

screws on end of Ball Screw (see

Figure 3.4).

4. Remove four cap head screws from

Y-axis Motor Mount (see Figure 3.3).

NOTE: Remove any paint around motor mount

that could cause misalignment.

5. Use four cap head screws from step

4 to mount Y-axis Motor onto Y-axis

Motor Mount. Wire loom should

face toward oor (see Figure 3.3).

Make sure motor and motor mount

faces are ush.

6. Aer ghtening four cap head

screws, back them o one-quarter

turn so motor is free to self align.

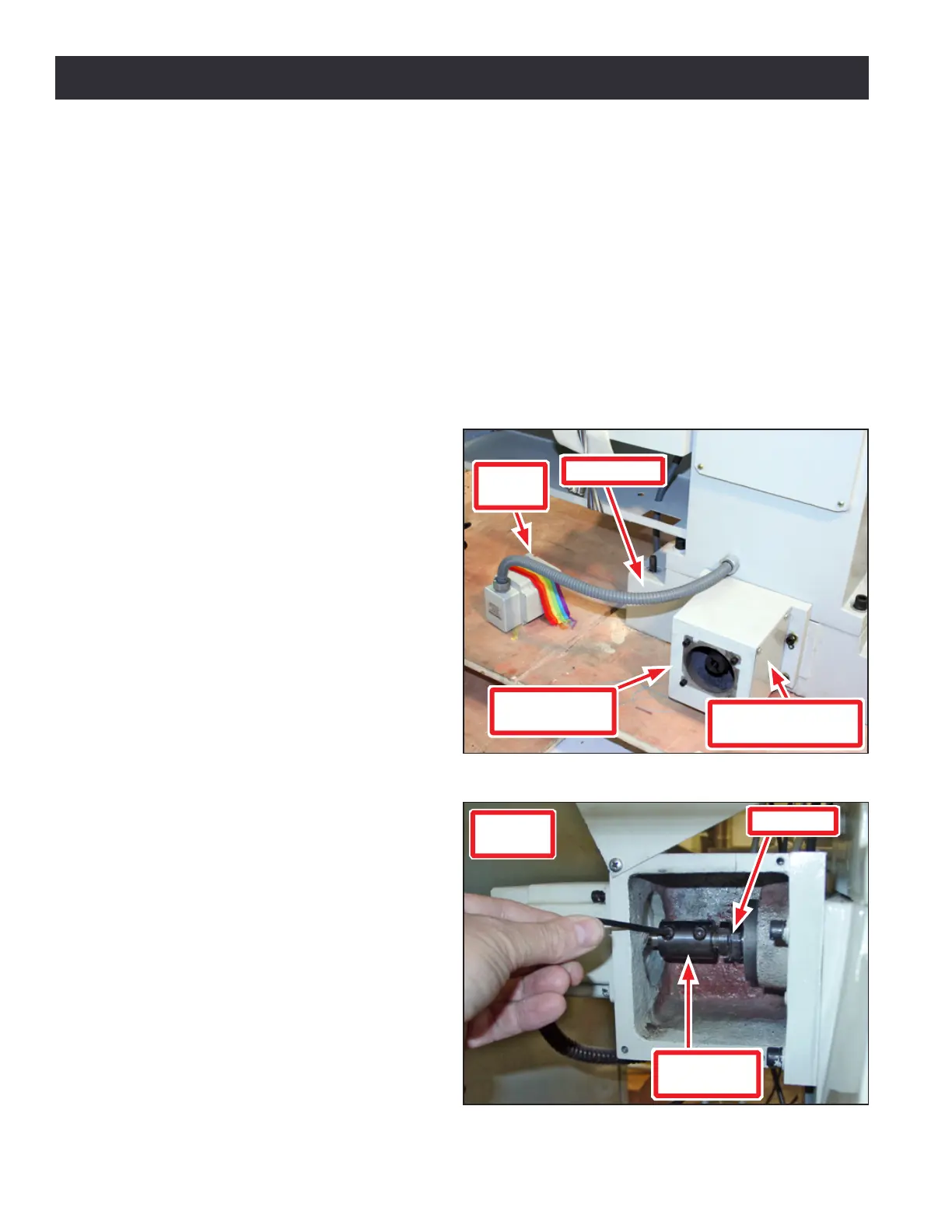

Figure 3.4

Coupling

Box

Motor Shaft

Coupling

Ball Screw

Figure 3.3

Y-axis Motor

Mount

Wire Loom

Y-axis Motor Mount

Cover Plate

Y-axis

Motor

Loading...

Loading...