Chapter 2

22

UM10350_PCNC770_Manual_0916A

Site Planning and Prep

2. Site Planning and Prep

This secon covers required site preparaons prior to placing PCNC mill in service.

2.1 General Site Requirements

The area should be well lit, dry, have proper venlaon, provide for unobstructed machine

moon/operaon, and ensure unrestricted access to PCNC mill controls.

2.1.1 Space Requirements

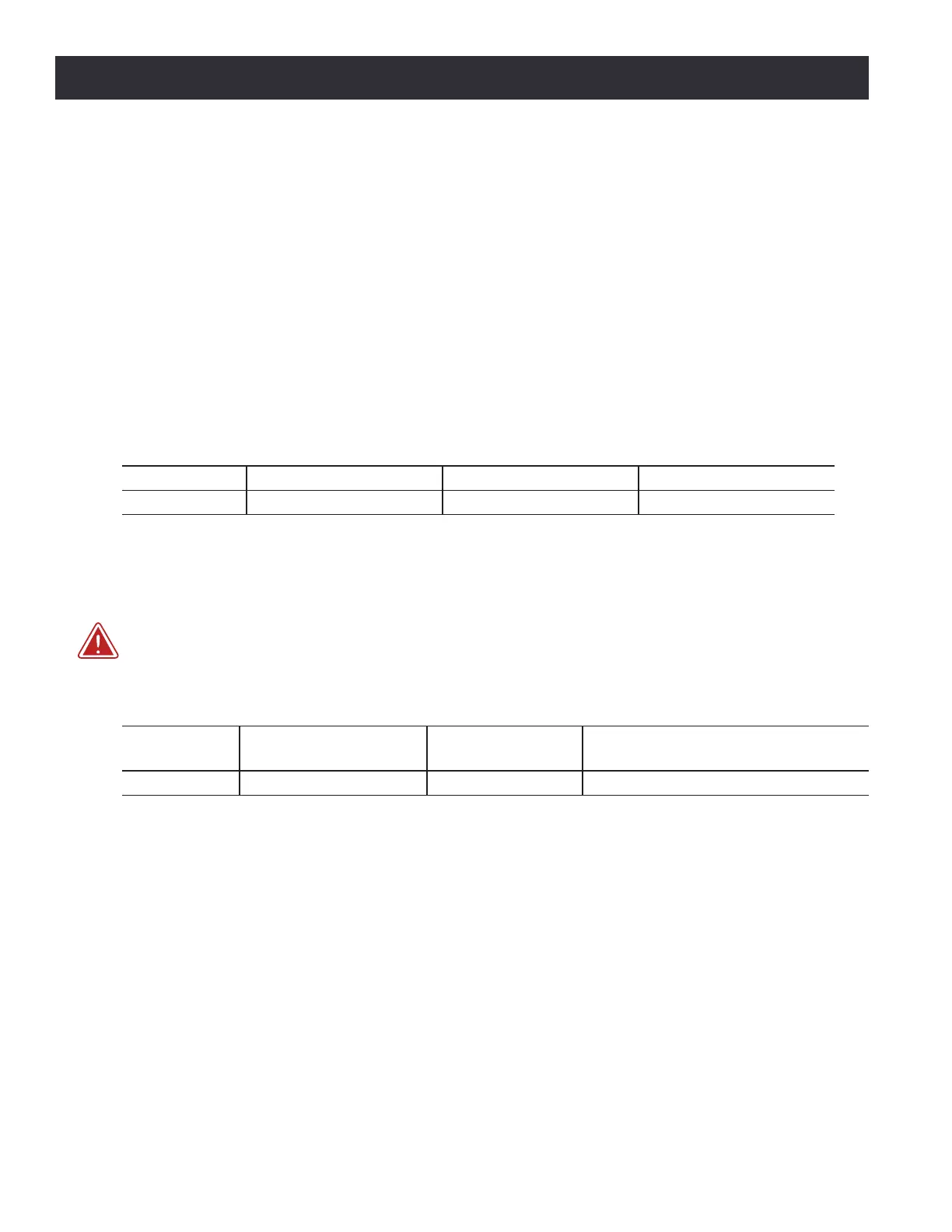

Minimum oor space requirements are as follows:

Width Depth Height

PCNC 1100 67” 43” 84”

PCNC 770 60” 40” 73”

NOTE: Allocate addional space to allow access to rear of mill for maintenance or repairs.

2.2 Electrical Requirements

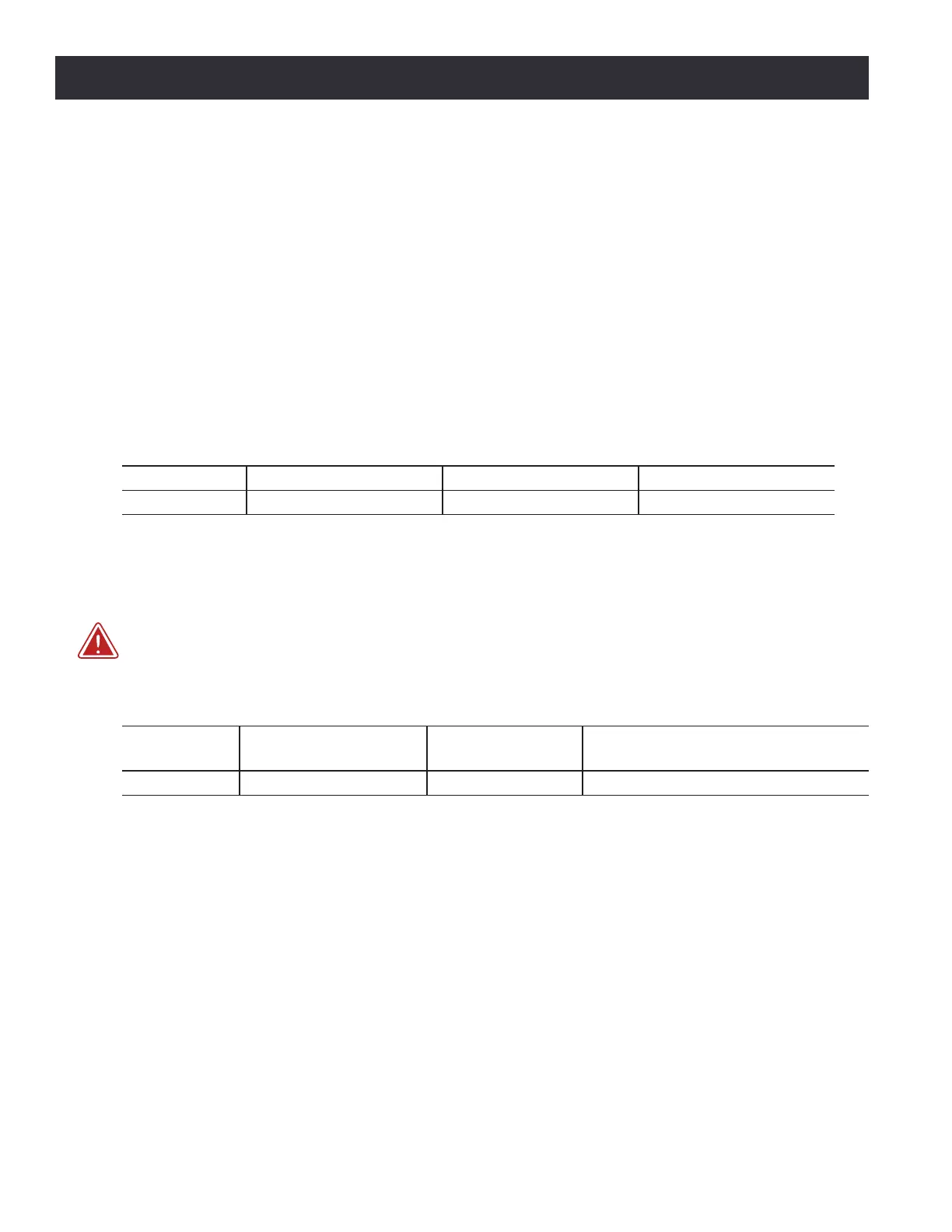

WARNING! Electrical Shock Hazard: Electrical connecons must be performed by a cered

electrician. Failure to do so may result in injury or death.

Primary Secondary Recommended Circuit Amperage

PCNC 1100 200-250 VAC, 50/60 Hz 115 VAC, 50/60 Hz

20 A primary

15 A secondary

PCNC 770 115 VAC, 50/60 Hz N/A 20 A

2.2.1 Grounding

All power inputs to PCNC mills must be properly grounded. Check connuity between bare metal on

mill frame and true earth ground (water pipe or similar) to ensure proper grounding.

2.2.2 Plug Pattern

The PCNC 1100 is shipped with a 3-wire conductor; no electrical plug is included. There are several

dierent NEMA (Naonal Electric Manufacturers Associaon) and non-NEMA plug paerns that

can be used. The PCNC 770 is shipped with a 5-20P plug. This plug is designed to be used with a

5-20R receptacle.

Loading...

Loading...