Chapter 5

44

UM10350_PCNC770_Manual_0916A

Intro to PathPilot

5. Intro to PathPilot

5.1 Making Your First Part

This chapter outlines how to make your rst

part with a Tormach mill. It assumes that

you have no prior experience running a part

program on a CNC (computer numerically

controlled) mill. Even if you have previous

CNC experience, following this tutorial

gives you an introducon to the controls

of the mill. Aer reading this chapter,

read chapters 6 and 7 for details on the

PathPilot

®

operang system. This chapter is

only intended to be an introducon to the

PathPilot interface and several basic tasks.

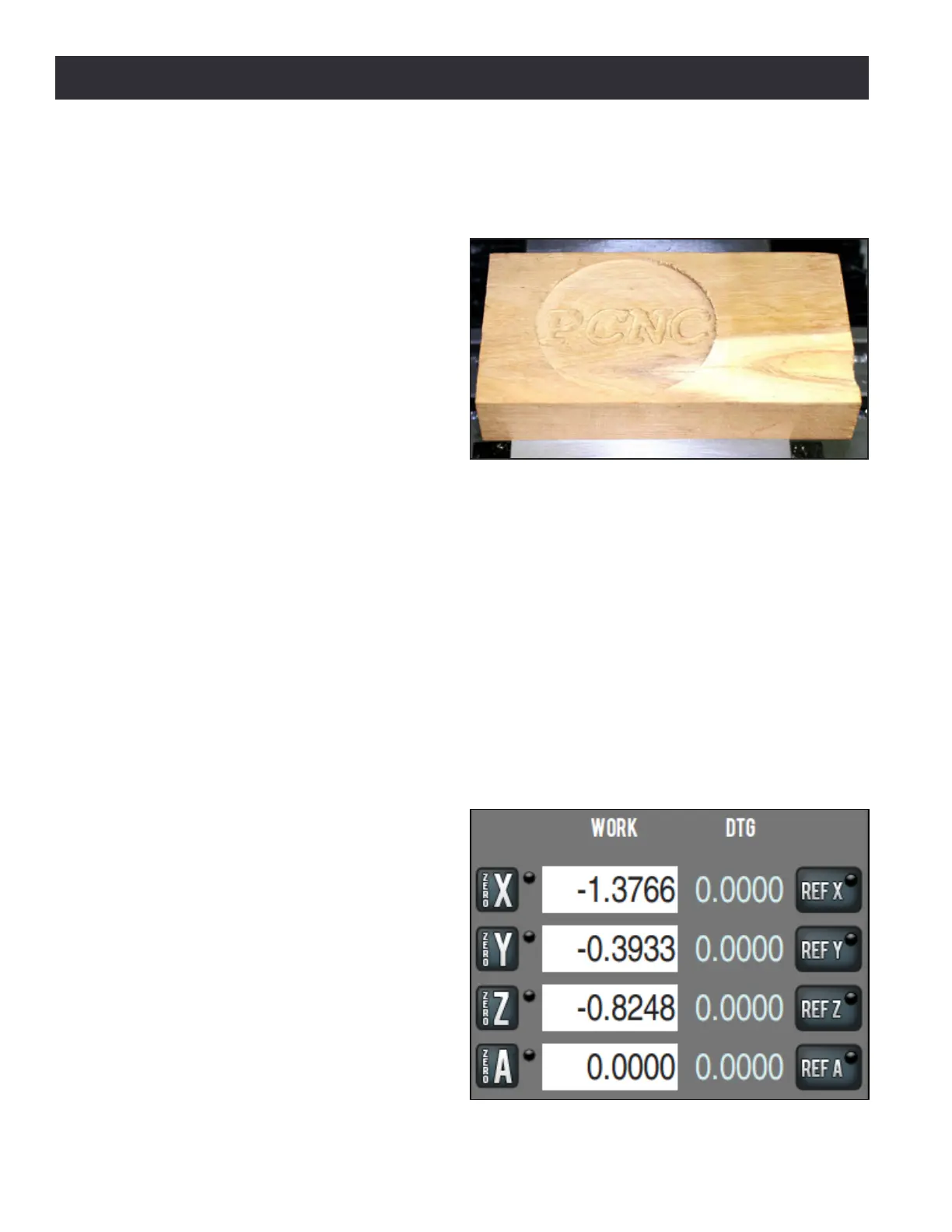

The rst part program uses two tools – a 3/8” end mill and a 1/8” end mill – to make a shallow

circular pocket and engrave the text PCNC in a wood 2” x 4” (see Figure 5.1). Two tools are used to

give you an introducon to tool changes and the dierence between work osets and tool length

osets. For operators with the oponal automac tool changer (ATC), we recommend using manual

tool changes for this rst part to keep things simple.

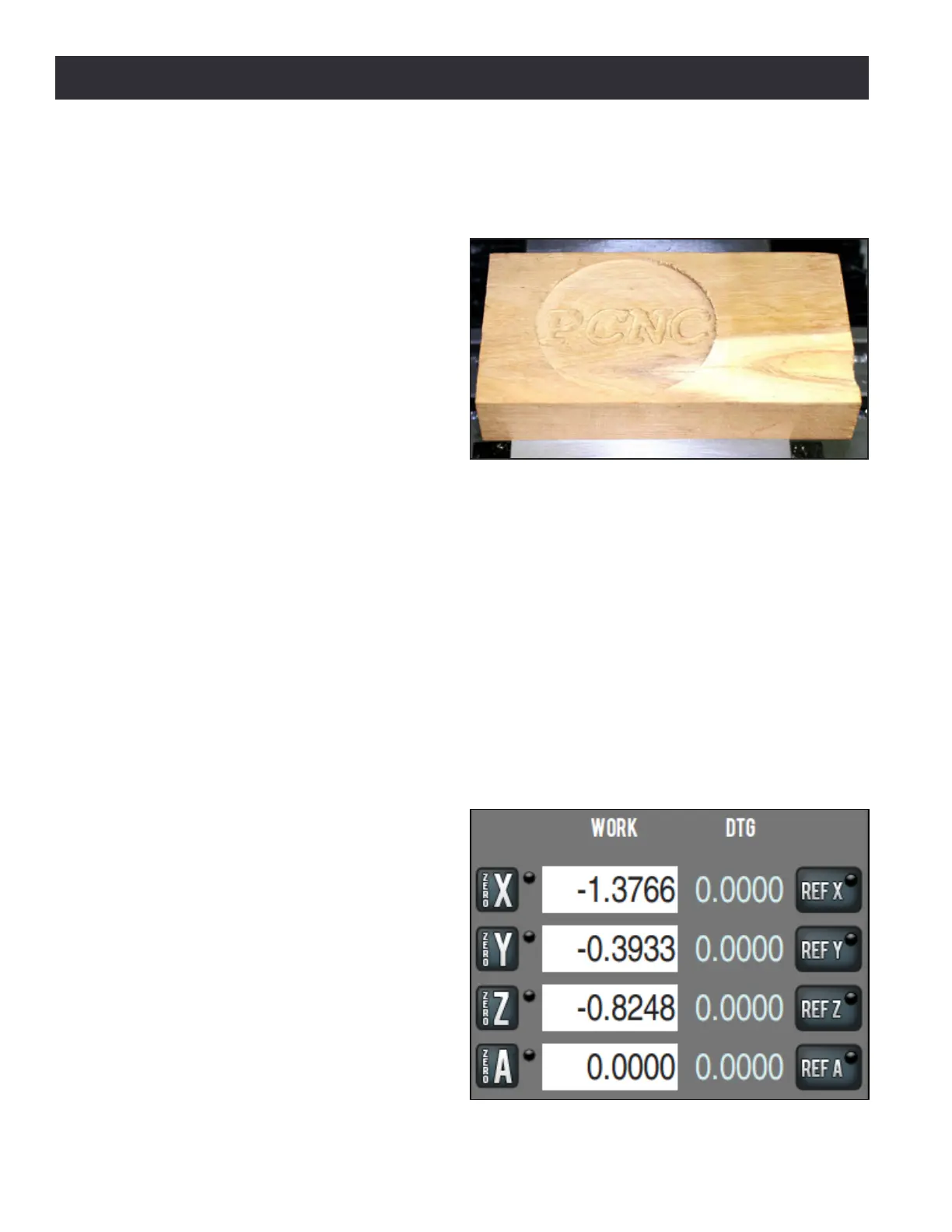

5.1.1 Referencing the Mill

Follow the power o/on procedure in chapter 3, Installaon, to turn the PathPilot controller and

mill on. Aer clicking the ashing Reset buon, you can reference the X-, Y-, and Z-axes. You should

reference the Z-axis rst to help avert a crash as it moves the tooling as far as possible from a

workpiece or vise. All three axes can be referenced simultaneously by pressing the Ref buons in

rapid succession (see Figure 5.2).

The axes should be referenced before

operang the mill to establish so limits

to protect the mill from over travel and to

give meaning to work oset values. Aer

referencing the axes, the LEDs on the Ref X,

Ref Y, and Ref Z buons turn green, indicang

that the mill has been referenced. While

you can jog the mill before referencing, you

should not run parts unl the mill has been

referenced. Should a home or limit switch

fail to work, manually reference the mill as

discussed in chapter 10, Troubleshoong.

Figure 5.1

Figure 5.2

Loading...

Loading...