Chapter 7

98

UM10350_PCNC770_Manual_0916A

Programming

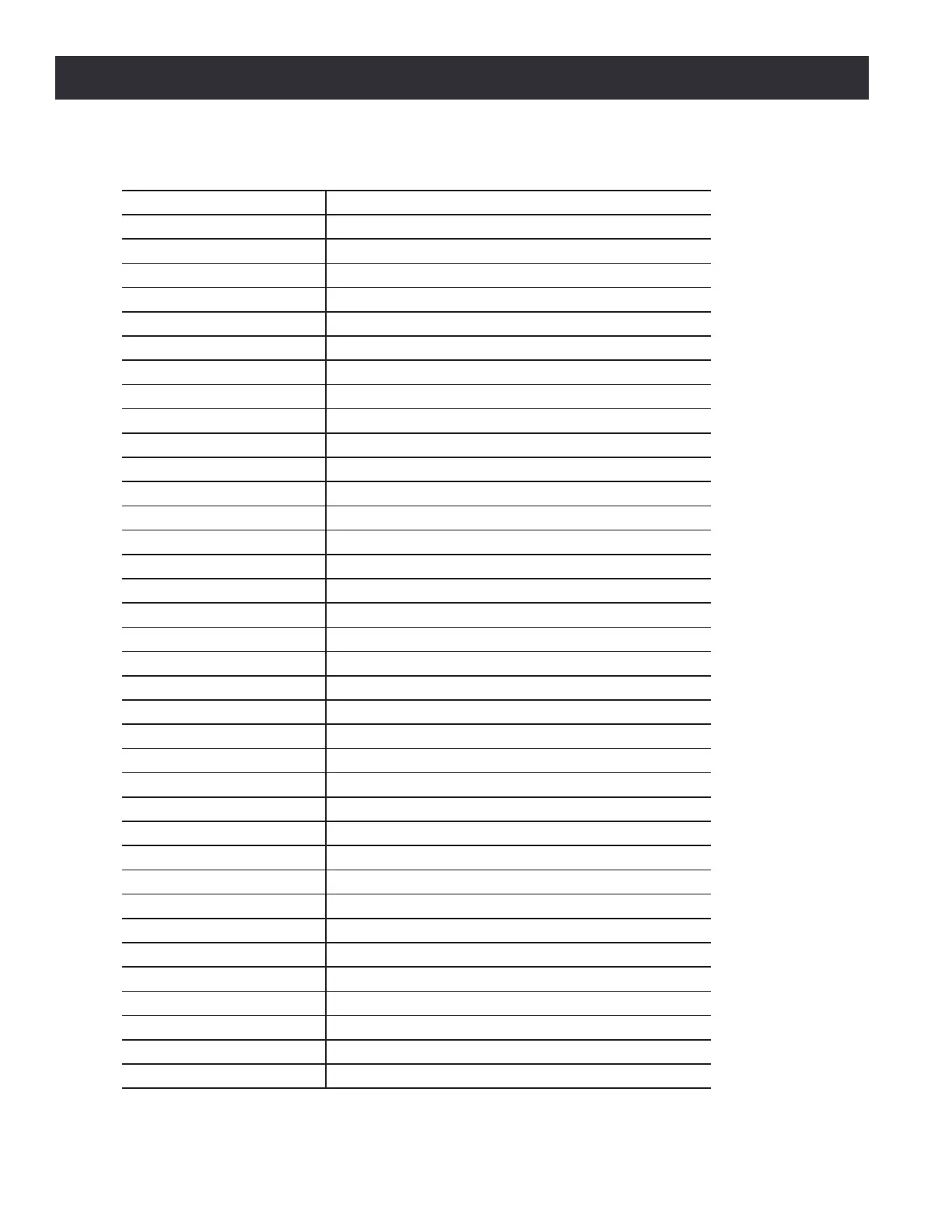

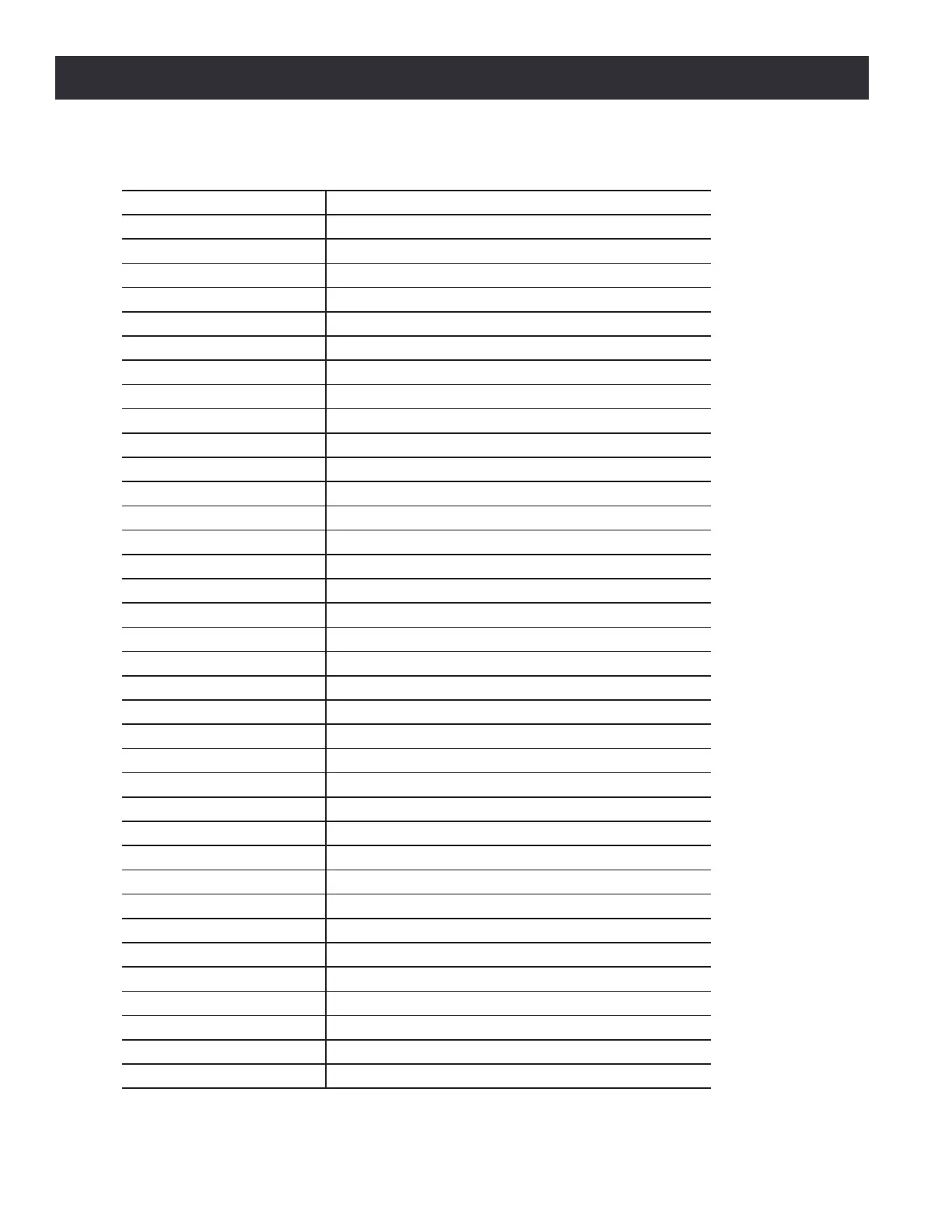

Summary of G-codes

G04 Dwell

G07, G08 Diameter/radius mode – Do not use G08

G10 L1 Set tool table entry

G10 L10 Set tool table – calculated – workpiece

G10L11 Set tool table – calculated – xture

G10 L2 Set work offset origin

G10 L20 Set work offset origin – calculated

G17, G18, G19 Plane selection

G20/G21 Inch/millimeter unit

G28 Return home

G28.1 Reference axes

G30 Return home

G33 Spindle sync. motion (e.g. threading)

G33.1 Rigid tapping

G40 Cancel cutter radius compensation

G41/G42 Start cutter radius compensation left/right

G41.1, G42.1 Dynamic Cutter Compensation

G43 Apply tool length offset

G49 Cancel tool length offset

G53 Move in absolute machine coordinate system

G54 Use xture offset 1

G55 Use xture offset 2

G56-58 Use xture offset 3, 4, 5

G59 Use xture offset 6 / use general xture number

G61/G61.1 Path control mode

G64 Path control with optional tolerance

G73 Canned cycle – peck drilling

G76 Multi-pass threading cycle

G80 Cancel motion mode (including canned cycles)

G81 Canned cycle – drilling

G82 Canned cycle – drilling with dwell

G83 Canned cycle – peck drilling

G85 Canned cycle – boring, no dwell, feed out

G86 Canned cycle – boring, spindle stop, rapid out

G88 Canned cycle – boring, spindle stop, manual out

G89 Canned cycle – boring, dwell, feed out

G90, G90.1 Absolute distance mode

(...continued)

(connued on next page...)

Loading...

Loading...