Chapter 10

201

UM10350_PCNC770_Manual_0916A

Troubleshooting

Axes Drive Subsystem Checklist

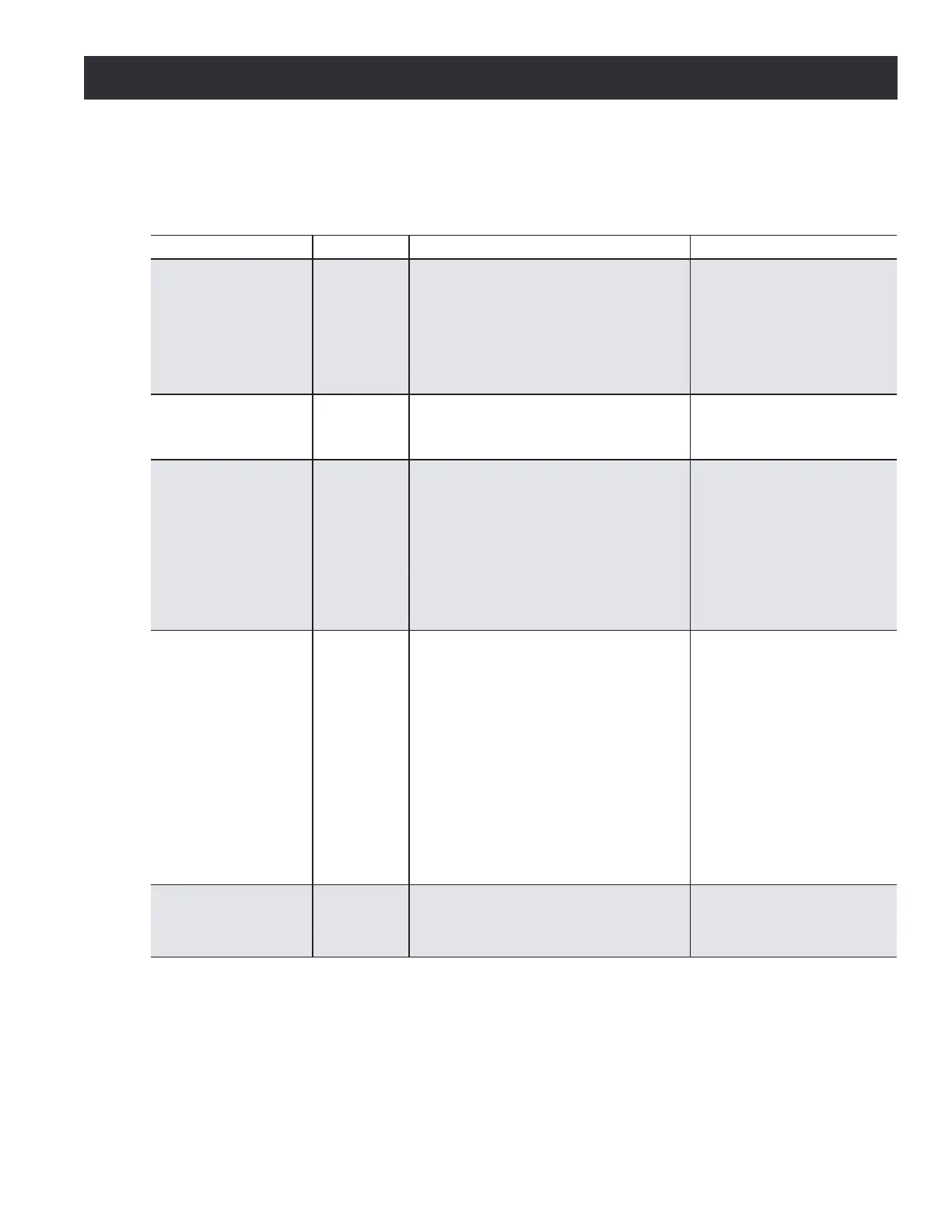

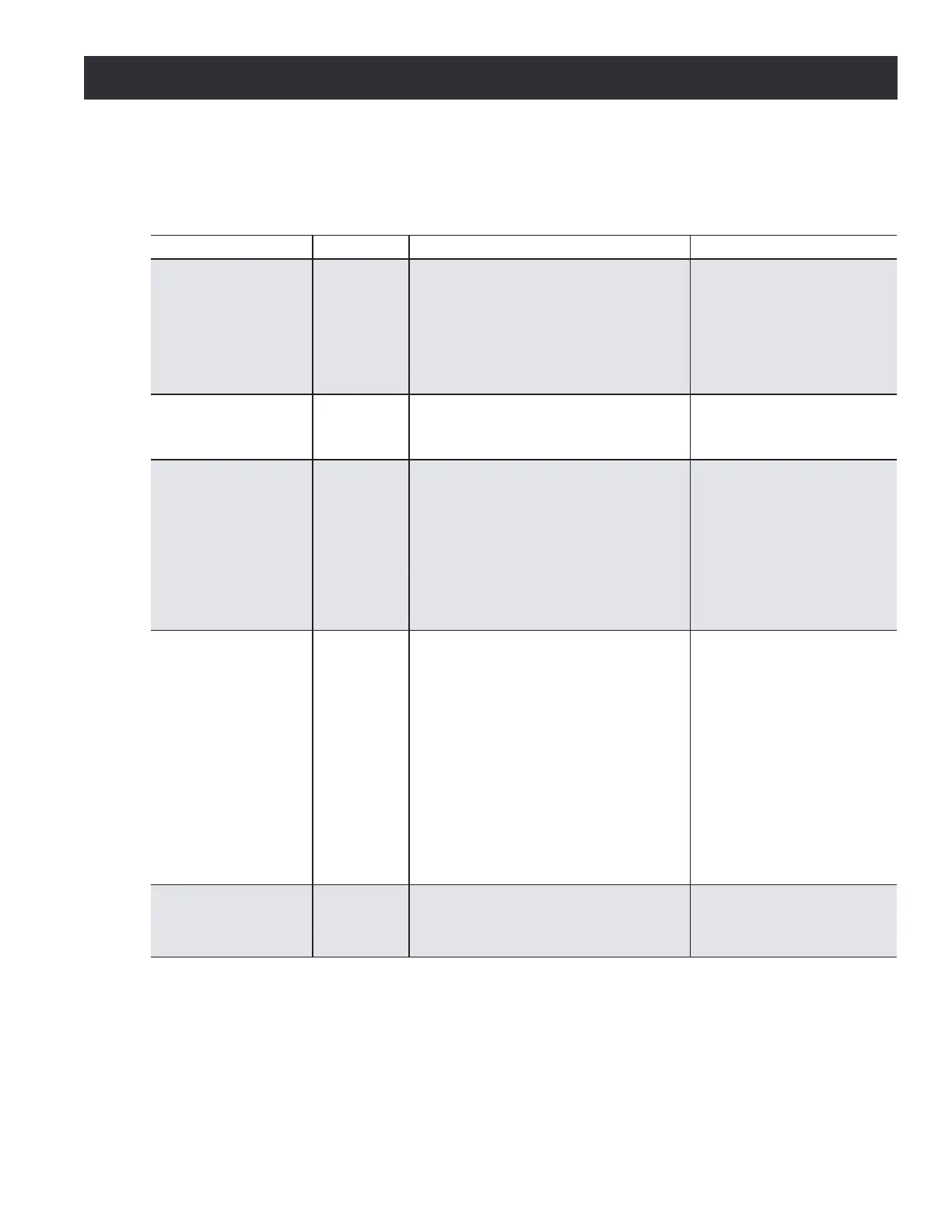

Table 4.8 — Steps are lost on axis travel

NOTE: Consult Table 4.2 and 4.5 for more information on lost steps.

Possible Cause Probability

Action to Identify Cause of Problem

Discussion

Improper use of tool

offset (G43), work

offset (G54-59), or

cutter compensation

(G41-42)

High See Motion Test later in this chapter

Common cause of a

perceived loss of position or

lost steps is operator error.

Please refer to chapter 7,

Programming, for details on

using mill offsets in PathPilot.

Spindle tooling not

properly locked

down (Z-axis only)

High

Ensure the cutter is not slipping in the

holder or that the tool holder is not

pulling out of the spindle collet.

—

Motor coupling loose

or cracked

Low Inspect

You may nd it useful to

run the axis with the cover

removed. A paint line from

shaft through coupling to

screw can be used to see if

there is any movement over

time. Use caution; keep away

from the rotating parts.

Holding brake not

releasing (Z-axis only)

Low

Z-axis will usually move down properly

but will not move up.

You should be able to

hear the motor cogging

whenever you command

the axis to move. It should

be noted that usually the

brake alone does not have

the torque to cause a loss

of step. Typically a condition

such as poor lubrication

combined with a defective

Z brake are required to

actually lose position.

Controller or

operating system

problem

Low

Restart the controller and send the

log le in the log les directory to

info@tormach.com.

—

(connued on next page...)

Loading...

Loading...