Chapter 10

204

UM10350_PCNC770_Manual_0916A

Troubleshooting

• The wrong diameter tool used in the CAM program (i.e., many 1/2” end mills are not

actually .500”)

• Mill referencing to the part was performed improperly and/or relying on the end of travel

limit switches to set mill osets

• Fixturing does not secure work, or does not facilitate repeatable mounng of work from one

piece to the next

These are what we call process errors, and have lile to do with a problem residing with the mill itself.

The scope of this poron of the troubleshoong guide does not cover soluons to process errors.

It is imperave to divide a given setup into manageable porons so one can focus on where the

problem really lies. Is it a process problem, or is it a mill problem? In order to isolate mill problems

from process problems, the process must be removed from the setup.

Moon Test

The goal of this test is to measure mill moon explicitly, thus eliminang process-based problems.

In this instance, the X-axis is checked, but a similar process can be used on the Y- and Z-axis as well:

1. Be sure that G40 and G49 show up in the modals list at the top of the screen.

2. Mount a quality dial indicator on the mill bed, orienng the plunger along the X-axis. Place it

near the end of travel.

3. Orienng the axis such that the indicator plunger contacts an appropriate surface on the

spindle head, move the X-axis such that the indicator is zeroed, then zero the X-axis DRO.

4. Aer moving the spindle head away from the indicator, proceed with exercising the axis: using

manual moves, or a very simple G-code program, move the axis at varying speeds (parcularly

focus on rapid speed). The more steps you run the axis through, the higher the probability

that a step is missed if there is a mill problem.

5. Return the axis to indicator zero, and

read what the DRO says. Allowing

for some lost moon (about .001”),

the value indicated on the DRO

should be 0. If not, then the mill is

missing steps.

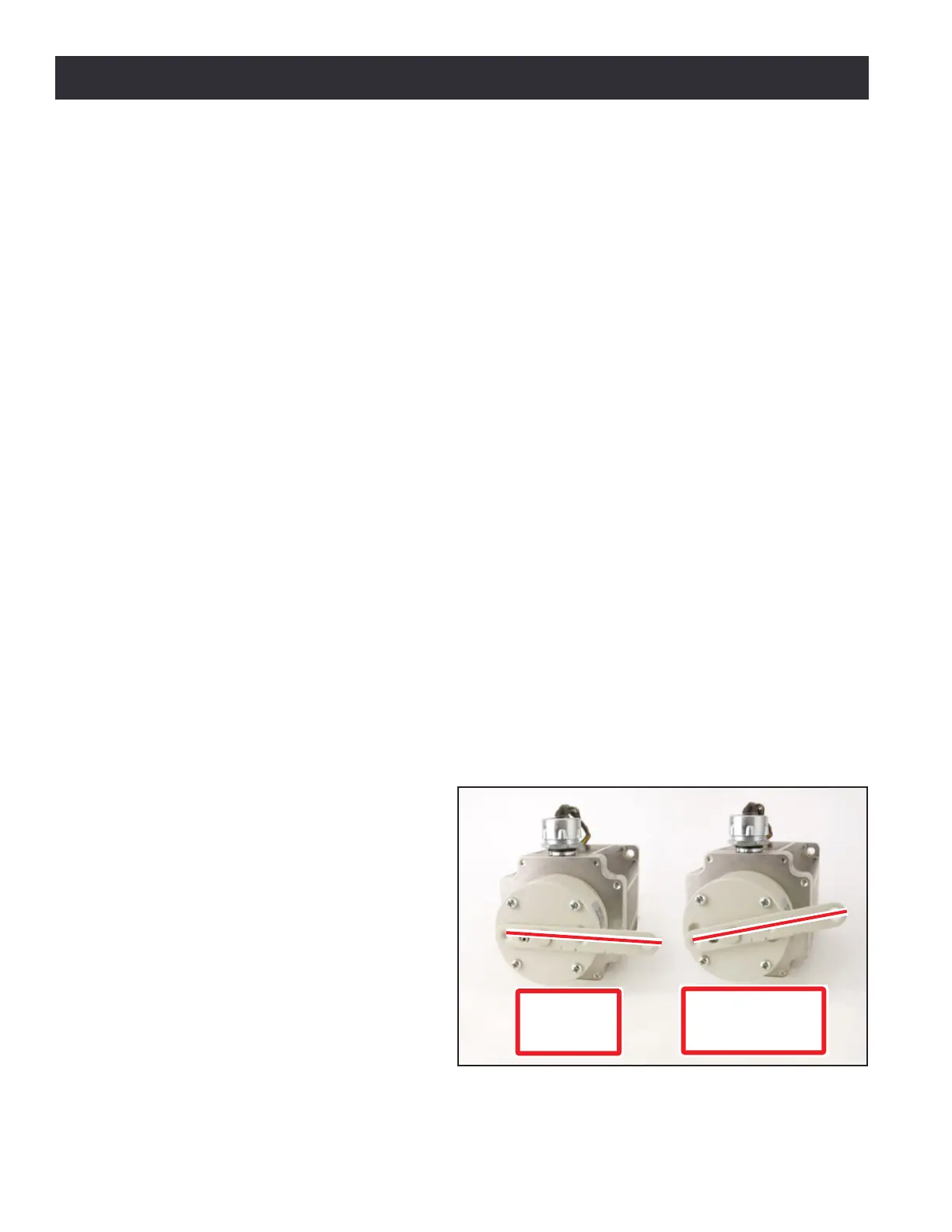

The Z-axis brake has a manual release (see

Figure 10.13) to disengage the brake. It is

not recommended to run your mill in the

disengaged posion.

Figure 10.13

Engaged

(normal

mode)

Disengaged

(maintenance

mode)

Loading...

Loading...