Chapter 10

209

UM10350_PCNC770_Manual_0916A

Troubleshooting

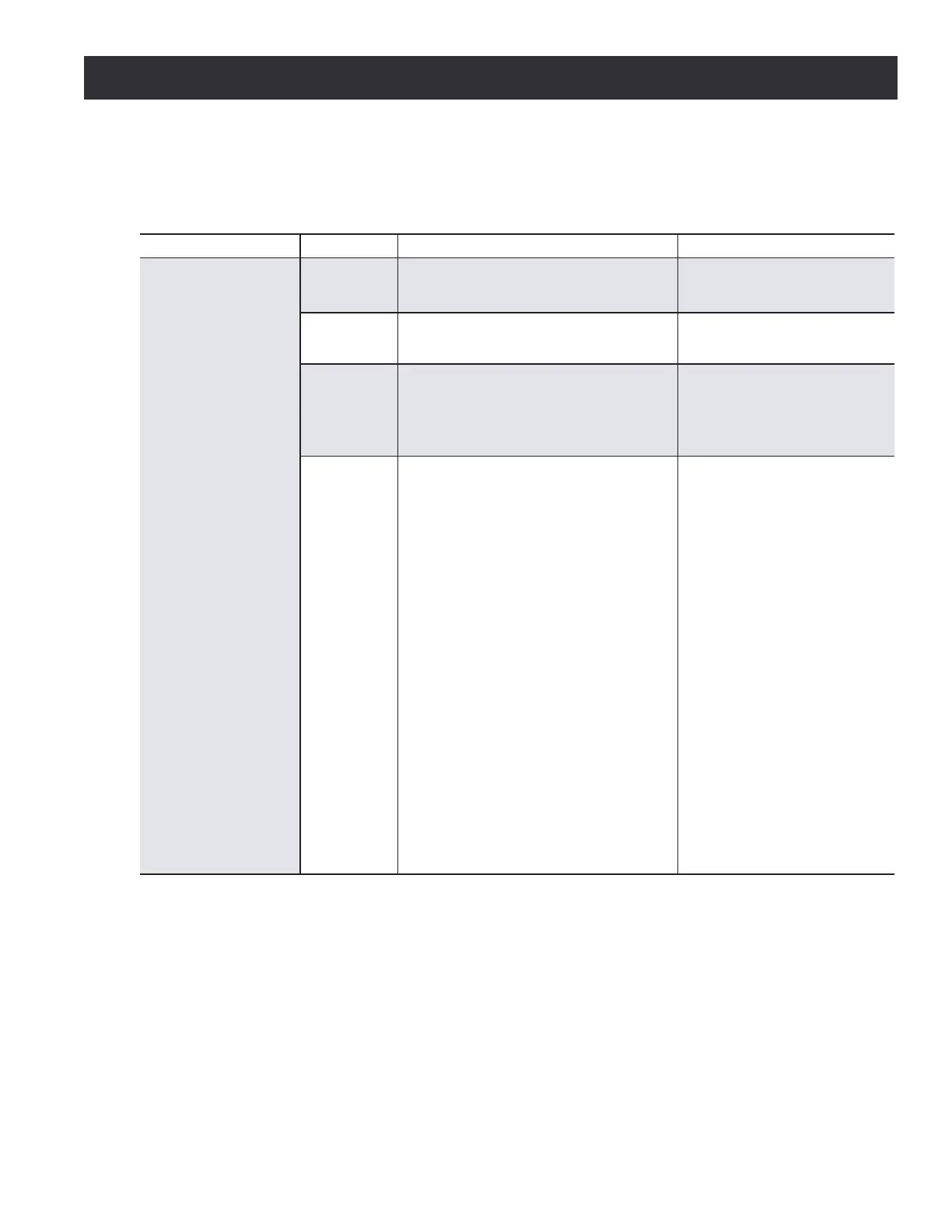

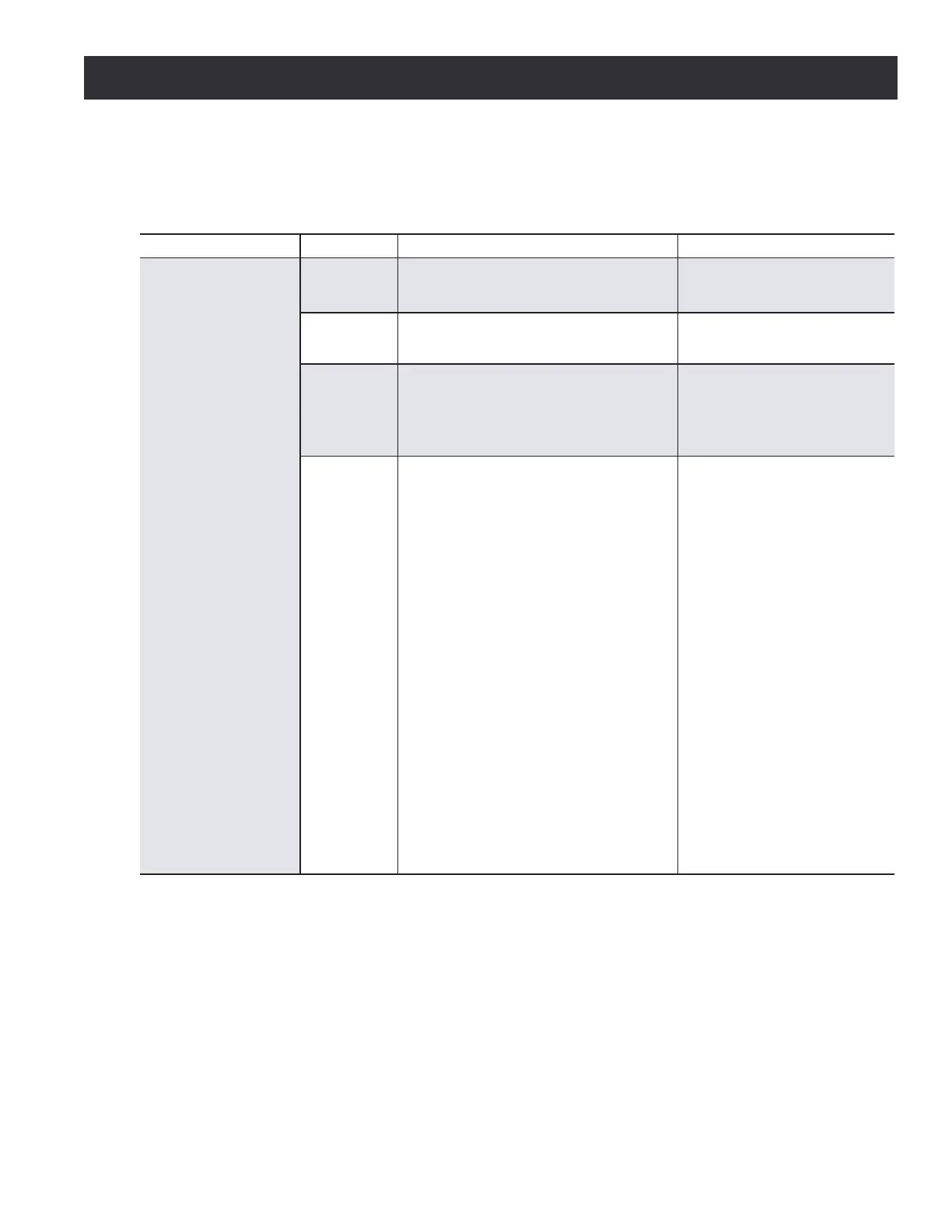

Spindle Drive Subsystem Checklist

Table 5.1 (...continued)

Spindle will not turn on in manual or auto

Possible Cause Probability

Action to Identify Cause of Problem

Discussion

No power to VFD

because contactor C2

is not energizing. This

can be checked by

checking the voltage

across 100 and 142 at

the VFD. Meter should

read 115-135 VAC.

High Spindle Lockout Key off or defective.

115 VAC measured from wire

100 to wire 105 when OK.

Medium

Spindle cover door not holding spindle

door switch closed or switch defective.

115 VAC measured from wire

100 to wire 106 when OK.

High Loose wires in circuit

Power off and search for

loose wires. Power on when

nished and check operation.

Low

Control board not providing run

command or holding contact on C2

between wires 106 and 107 defective.

In manual mode, press the Spindle Stop

Switch. With the door open, press the

Spindle Start Switch and listen for a soft

audible click on the control board.

If you hear this click (from a relay

contact on the board), the board is

functioning properly.

Ensure you have 115 VAC

measured from wire 100

to wire 106. Make a jumper

wire and, using proper care

associated with live circuits,

momentarily jumper wires

106 and 107. If contactor

C2 pulls in (you will hear an

audible clunk) while you have

the jumper on but drops out

as soon as you remove the

jumper, the holding contact

on C2 is defective. If C2 stays

powered on, the control

board is not passing the run

signal to the circuit. Make

certain you are commanding

the VFD to run. If so, the

control board is defective.

(connued on next page...)

Loading...

Loading...