Chapter 10

213

UM10350_PCNC770_Manual_0916A

Troubleshooting

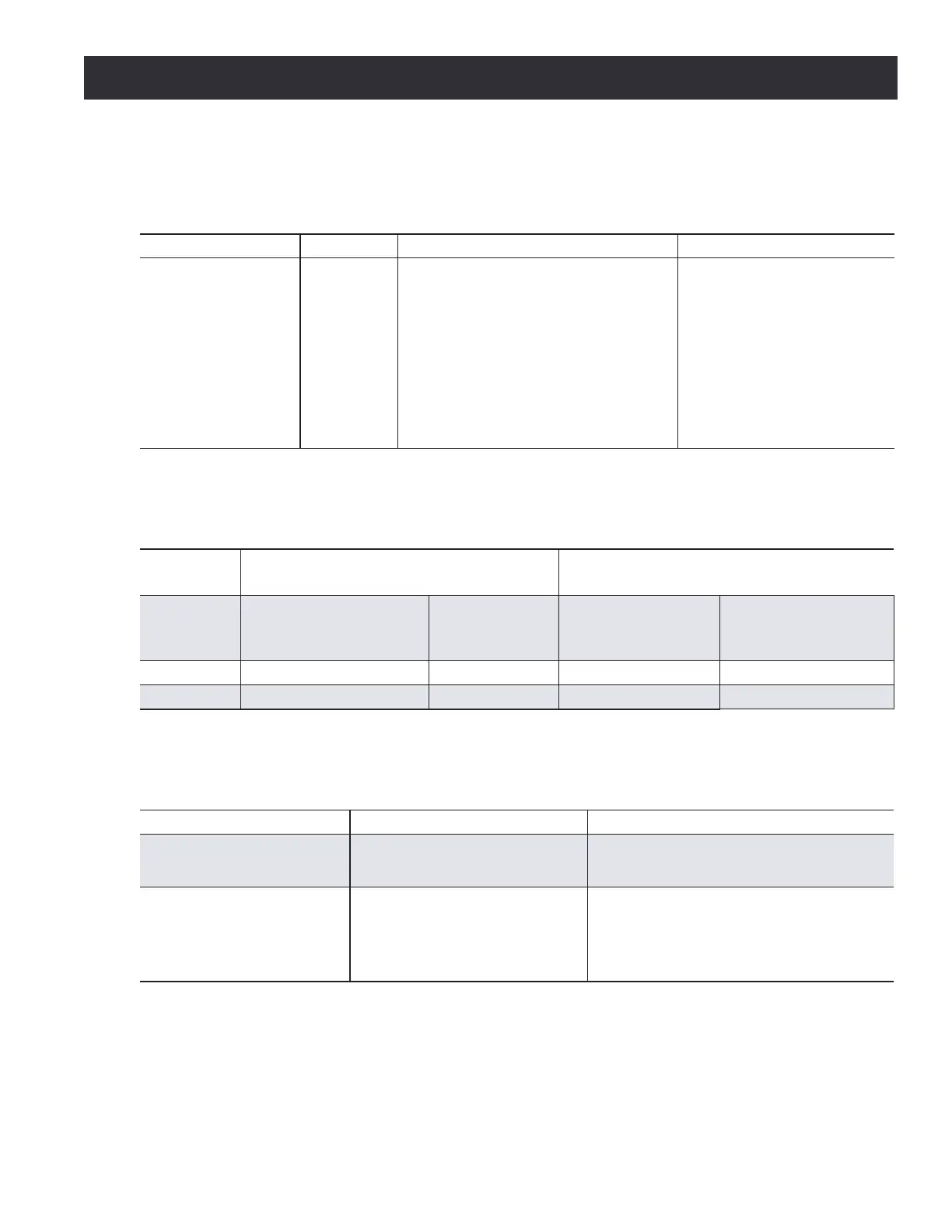

Spindle Drive Subsystem Checklist

Table 5.1 (...continued)

Spindle will not turn on in manual or auto

Possible Cause Probability

Action to Identify Cause of Problem

Discussion

Defective motor Low

Power off the VFD using the key

switch. Wait 30 seconds and measure

resistance between the leads of the

motor which are wire numbers 400,

401, and 402. Remember to take a tare

reading with your meter. Refer to Using

the Digital Multimeter for Electrical Tests

earlier in this chapter.

Resistance should be in the

range of 2-4 Ω. 0 Ω would

indicate the winding is shorted

and >1M Ω would indicate the

winding is open, both cases

indicate a defective motor or

compromised wiring to the

motor from the VFD.

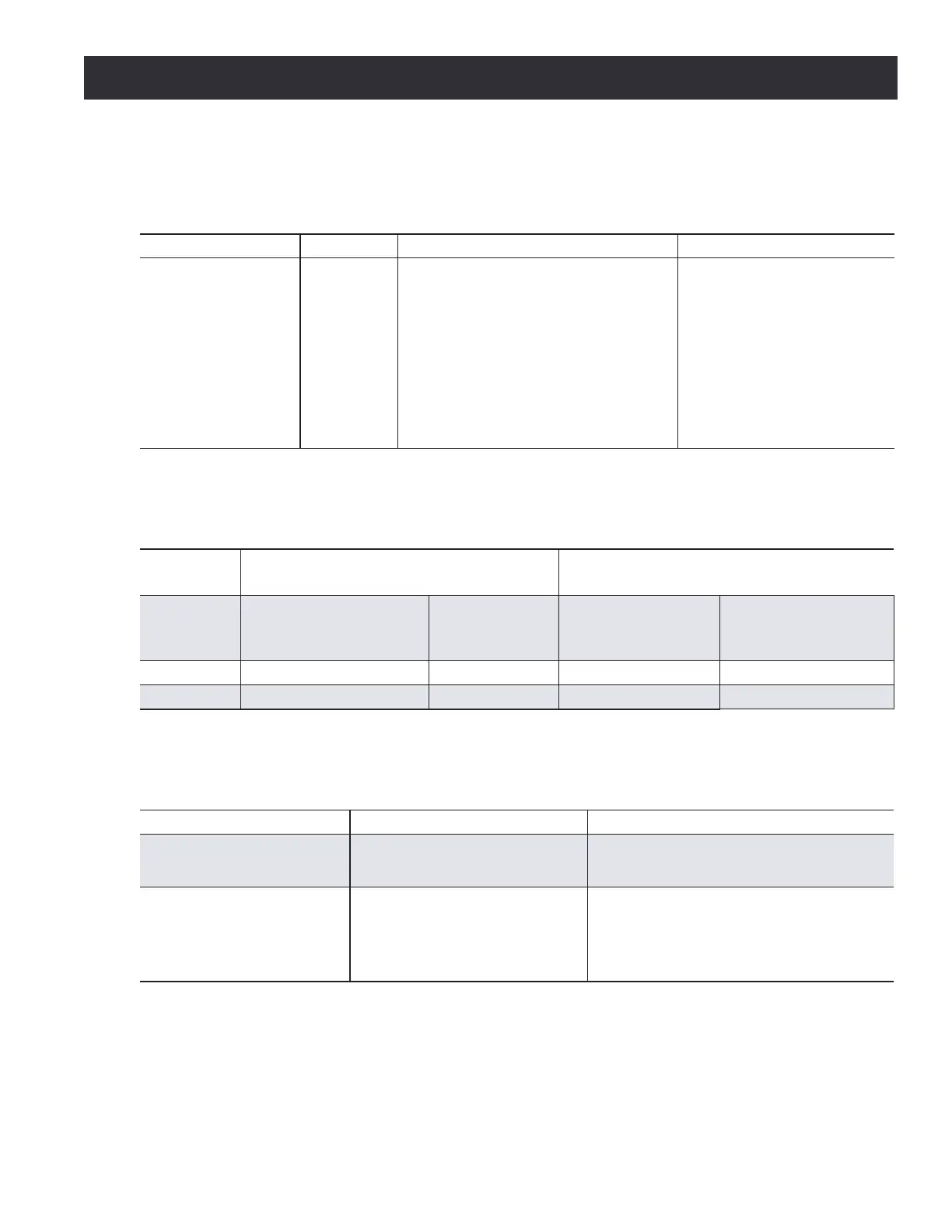

Spindle Drive Subsystem Checklist

Table 5.2a

Run and direction commands to drive

Command

From Card

Monitoring Points One Probe on Each Voltage Measured

Common wire number Wire number

Voltage when control

board command is on

Voltage when control

board command is

not on

Run J1-2 J1-3 20-28 VDC 0 VDC

Reverse J1-2 J1-6 0 VDC 20-28 VDC

Spindle Drive Subsystem Checklist

Table 5.2b

Main control board LED indicators for run and speed commands to drive

Mode Setting Indicator

Manual (front panel switch

turned to manual)

Spindle Start switch on Operator

Panel engaged.

Yellow LED D15 lights. Brightness is

proportional to speed.

Auto (front panel switch

turned to auto)

Spindle FWD button on controller

screen engaged.

Yellow LED D15 lights. Brightness is

proportional to speed. Green LED D10

lights and blinks at a rate proportional to

speed.

Loading...

Loading...