ChargePumpFlowTest(UsingTesterWithPressureGaugesand

FlowMeter)(MachineSerialNumbersbelow316000000)

Thechargepumpowtestshouldbeperformedifahydraulicproblemis

identiedthataffectsboththesteeringandliftcircuits.

Note:Thechargepumpprovidesmake-upuidforinternalhydrostat

componentsbeforeowisavailableforthesteeringandliftcircuits.Flow

measuredinthistestwillbelessthantotalchargepumpoutput.

1.Ensurethatthehydraulicuidisatnormaloperatingtemperatureby

operatingthemachineforapproximately10minutes.

2.Parkmachineonalevelsurfacewiththecuttingdeck(orimplement)lowered

andPTOswitchoff.Ensurethattheengineisshutoff.Settheparkingbrake

andblockthefrontwheelstopreventmachinemovement.

3.ReadallWarning,Cautions,andprecautionslistedatthebeginningofthis

section.

CAUTION

Beforeopeninghydraulicsystem,operateallhydrauliccontrolsto

relievesystempressureandavoidinjuryfrompressurizedhydraulic

uid.

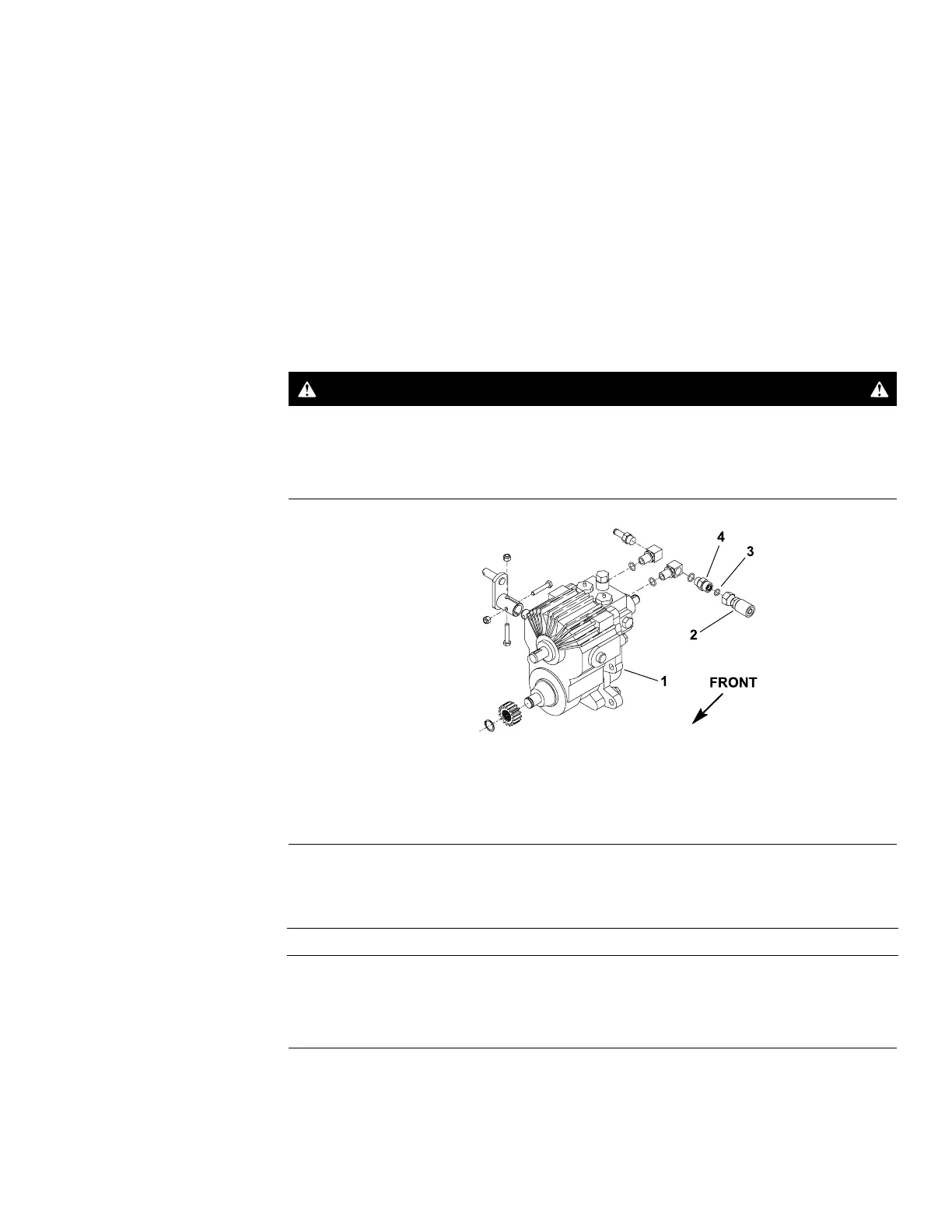

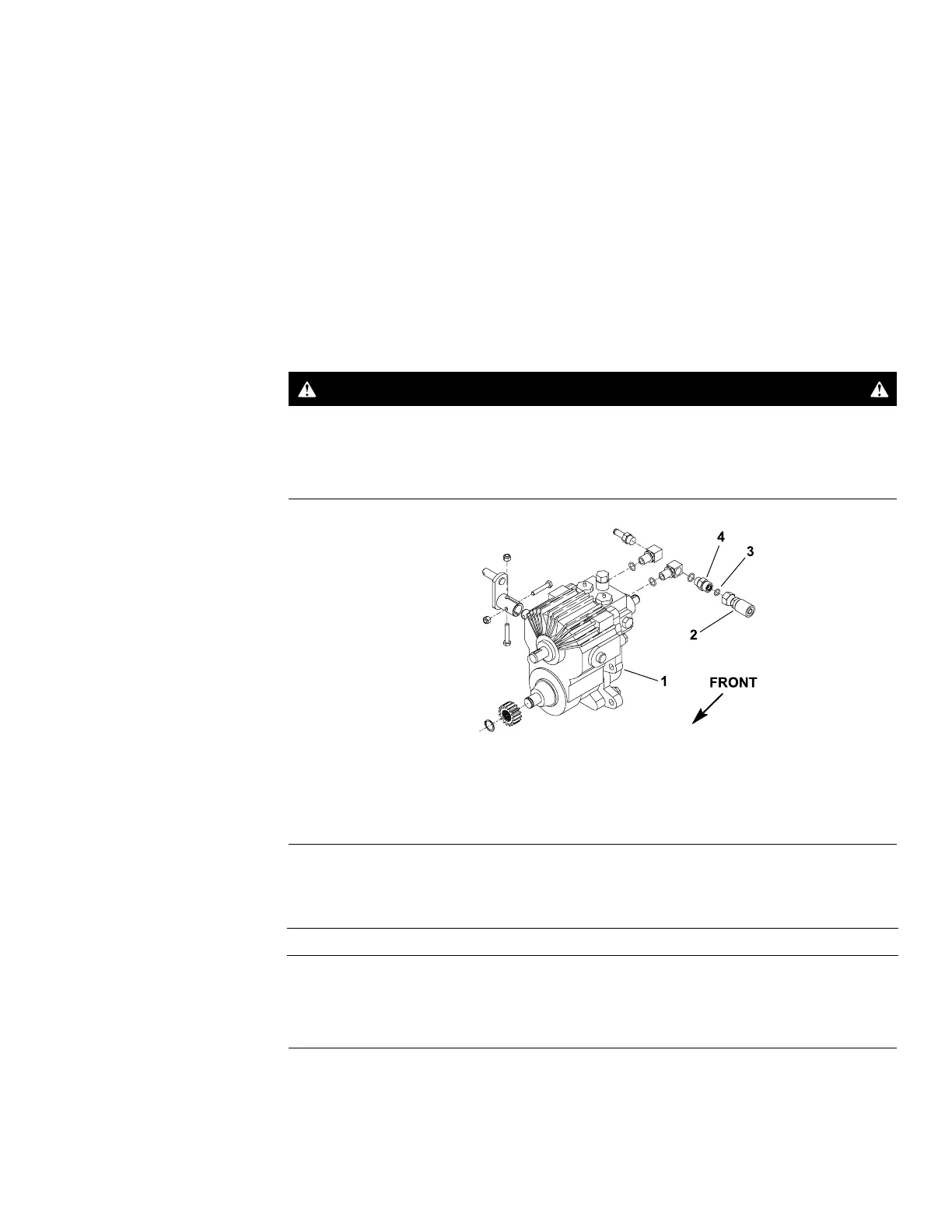

g230808

Figure66

1.Hydrostatictransmission

3.O-ring

2.Hydraulichose

4.Outlettting

4.Placeadrainpanunderthetransmission.Cleantheareaaroundthe

transmissionchargepumpoutlet(pressure)tting(Figure66).Disconnect

thehydraulichosefromtheoutlettting.

IMPORTANT

Ensurethattheuidowindicatorarrowontheowmeteris

showingthattheuidwillowfromthepump,throughthetester

andtothehydraulichose.

5.Connectinlethoseoftesterwithpressuregaugesandowmetertothe

transmissionchargepumpoutlet(pressure)tting.Connectthetesteroutlet

hosetothehydraulichosedisconnectedfromthetransmissionttinginstep

5.

Groundsmaster

®

3280-D/3320

Page5–57

HydraulicSystem:TestingtheHydraulicSystem

05138SLRevB

Loading...

Loading...