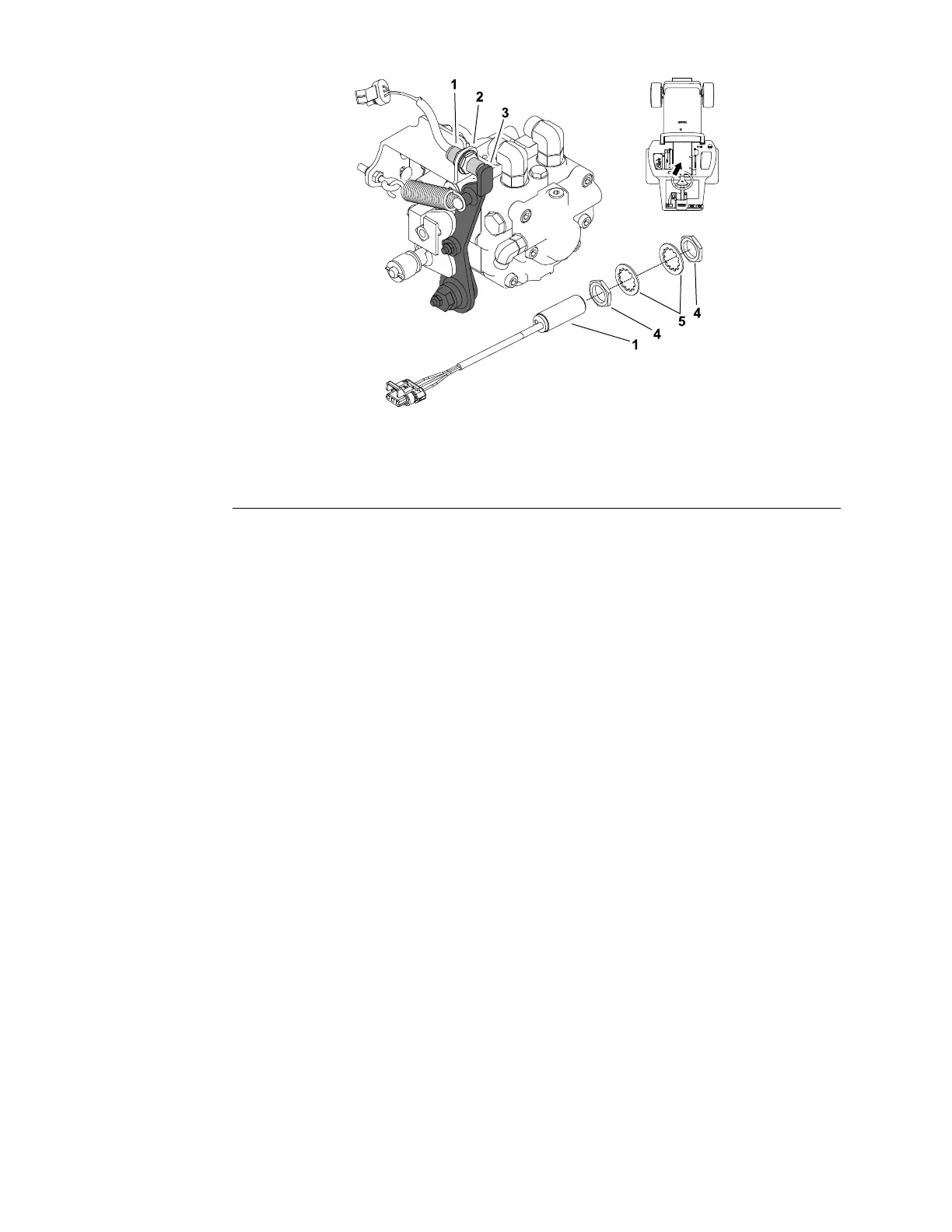

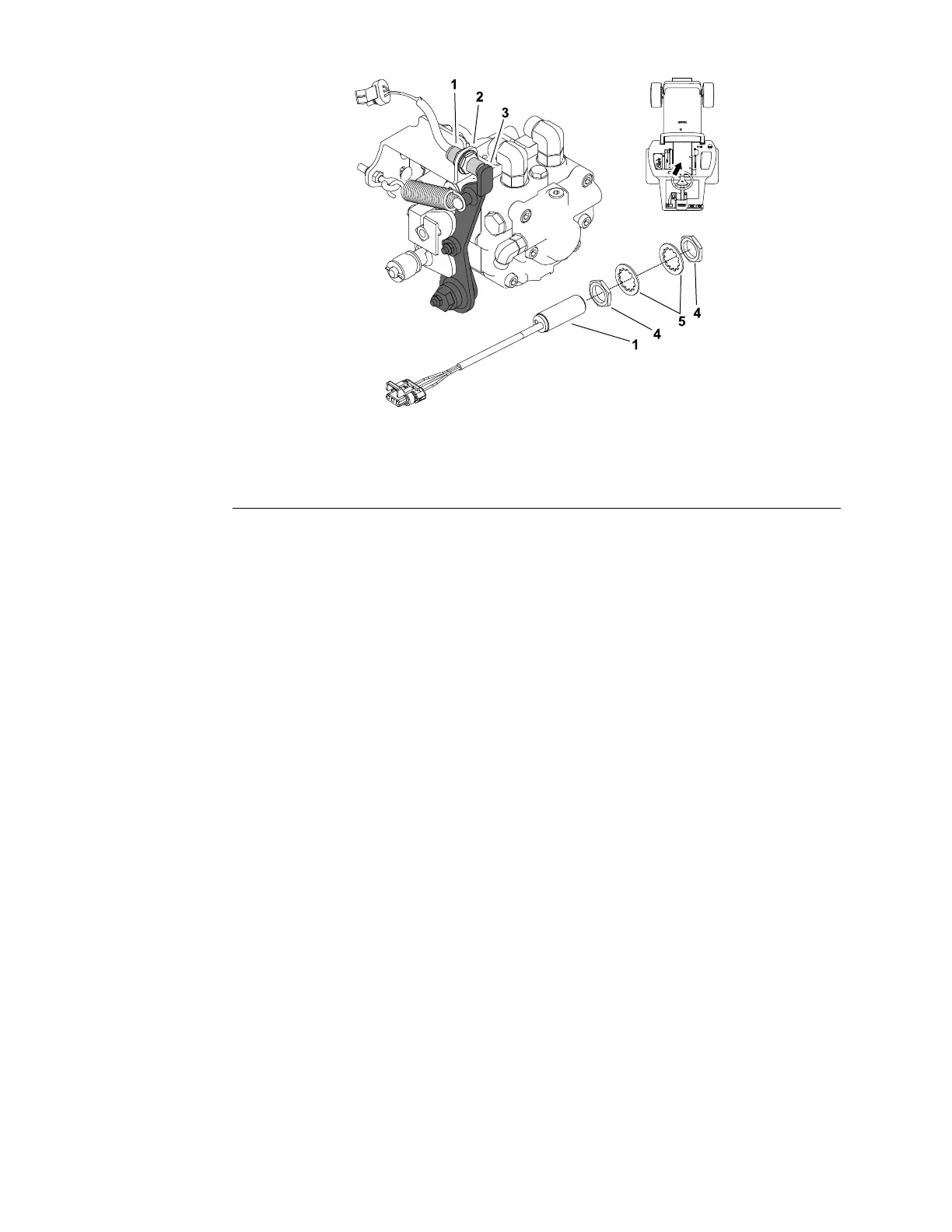

TractionNeutralSensor(MachineSerialNumberabove316000000)

g226812

Figure148

1.Tractionneutralsensor3.Neutralarm

5.Lockwasher(2each)

2.Sensorbracket4.Jamnut(2each)

Thetractionneutralsensorisanormallyopenproximityswitchthatcloseswhen

thetractionpedalisintheneutralposition.Thesensorislocatedundertheseat

andmountstoasensorbracketoverthehydraulicpump(Figure148).The

sensingplateforthetractionneutralsensoristheneutralarm.

TheStandardControlModulemonitorstheoperationofthetractionneutral

sensor.IfthekeyswitchisintheONpositionandthetractionpedalisinthe

neutralposition,theSCMneutralinputLEDshouldbeilluminated.

TestingtheTractionNeutralSensor

1.Parkthemachineonalevelsurface,lowerthecuttingdeck,settheparking

brake,andshutofftheengine.

2.Beforeyoudisconnectthetractionneutralsensorfortesting,ensurethat

youtestthesensoranditscircuitwiringasaSCMinput;refertoStandard

ControlModule(SCM)(page6–3).

3.IftheSCMveriesthatthesensorandcircuitwiringarefunctioningcorrectly,

thennomoreswitchtestingisnecessary.

4.IftheSCMdeterminesthatthetractionneutralsensorandcircuitwiringare

notfunctioningcorrectly,proceedwiththetest.

5.Raisetheoperatorseatandremovetheseatplate.

6.Locatethetractionneutralsensor.

7.TurnthekeyswitchtotheRUNposition(donotstarttheengine)andcheck

theLEDonthecableendofthetractionneutralsensor.TheLEDshouldbe

illuminatedwhenthetractionpedalisintheneutralposition.

8.WiththekeyswitchisstillintheRUNposition(donotstarttheengine),press

thetractionpedaleitherforwardorreverseandchecktheLEDonthecable

endofthetractionneutralsensor.TheLEDshouldnotbeilluminatedwhen

thetractionpedalispressed.

ElectricalSystem:TestingtheElectricalComponents

Page6–48

Groundsmaster

®

3280-D/3320

05138SLRevB

Loading...

Loading...