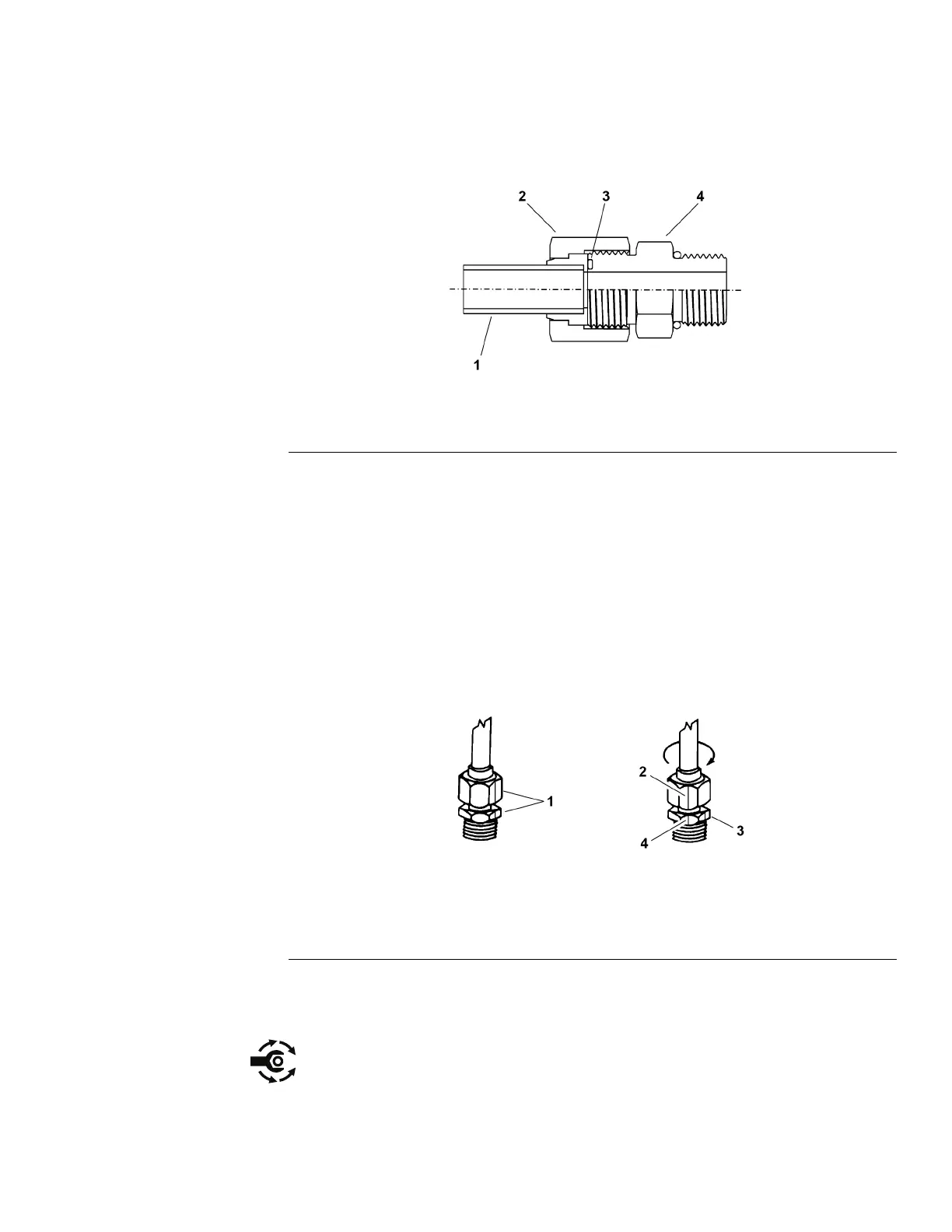

InstallingtheHydraulicHoseandTube(O-RingFaceSealFitting)

1.Ensurethatallthethreads,thesealingsurfacesofthehose/tube,andthe

ttingarefreeofburrs,nicks,scratches,orunwantedmaterial.

2.Tohelppreventahydraulicleak,replacethefacesealO-ringwhenyouopen

theconnection.EnsurethattheO-ringisinstalledandcorrectlyseatedinthe

grooveofthetting.LightlylubricatetheO-ringwithcleanhydraulicuid.

g221221

Figure37

1.Tubeorhose

2.Swivelnut3.O-ring

4.Fittingbody

3.Alignthehose/tubeagainstthebodyofthettingsothattheatfaceofthe

hose/tubesleevefullytouchestheO-ringinthetting(Figure37).

4.Useyourhandtothreadtheswivelnutontothetting.Whileyouholdthe

hose/tubeinalignmentwithawrench,useatorquewrenchtotightenthe

swivelnuttotherecommendedtorquevaluewithinthespeciedrangeof

torquevalues;refertotheHose/TubeInstallationTorqueT able(page5–10).

Thisproceduretotightentheswivelnutrequiresadrive-adapterwrench

(e.g.,crowfootwrench).

Note:Itmaybenecessarytouseadrive-adapterwrench(e.g.,crowfoot

wrench)toinstallahydraulictting;refertoCalculatingtheT orqueValues

WhenUsingaDrive-AdapterWrench(page2–7).

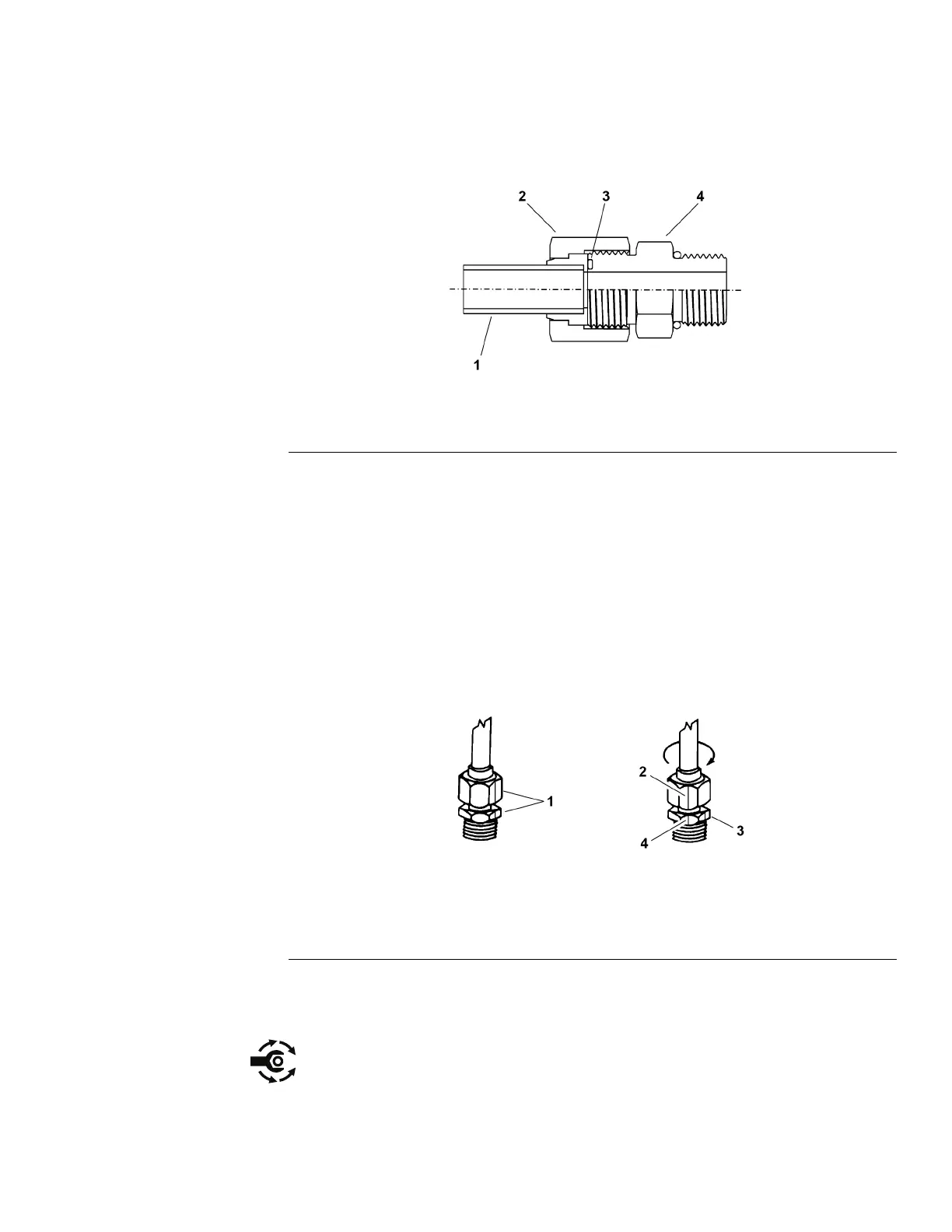

g221222

Figure38

1.Marknutandttingbody

3.Initialposition

2.Finalposition4.Extendline

5.Ifatorquewrenchisnotavailableorifspaceattheswivelnutpreventsthe

useofatorquewrench,usethealternativeprocedureFlatsFromWrench

Resistance(FFWR)givenbelow(Figure38).

A.Useawrenchtotightentheswivelnutontothettinguntilyoufeellight

resistancewiththewrench—approximately3.39N∙m(30in-lb).

B.Putamarkontheswivelnutandbodyofthetting.Holdthehose/tubein

alignmentwithawrenchtopreventthehose/tubefromturning.

Groundsmaster

®

3280-D/3320

Page5–9

HydraulicSystem:GeneralInformation

05138SLRevB

Loading...

Loading...