5. Lay a thin layer of filler sand on top of the DRS511 cable connector and the cable duct to

protect them.

Too much sand may deteriorate the flow properties of the filling

material as well as its strength.

CAUTION!

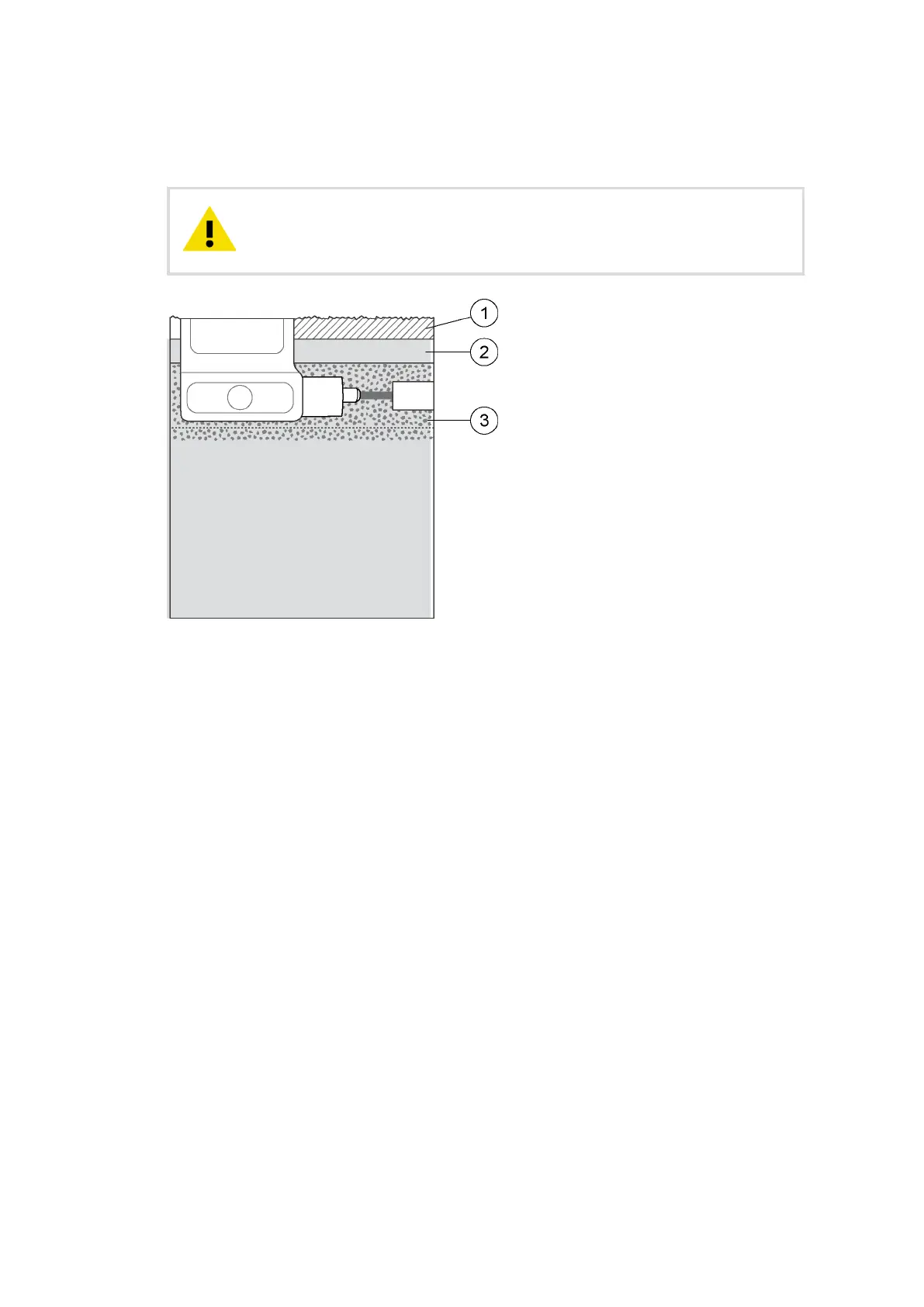

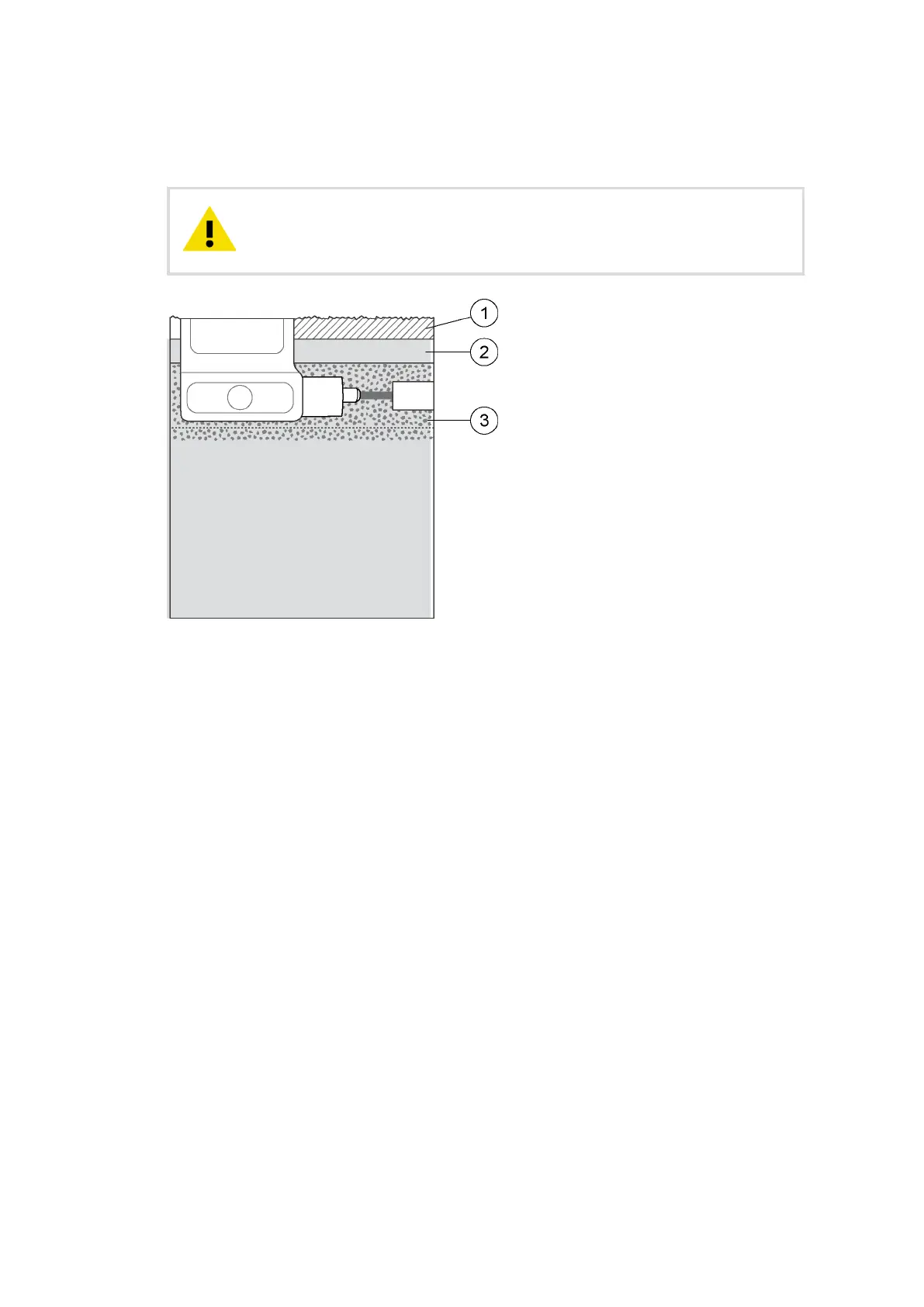

1 Elastomeric bitumen (optional)

2 Construction bitumen

3 Filler sand

6. Melt the construction bitumen in a suitable container according to manufacturer

specifications.

7. Check the sensor positioning again. See step 3.

8. Fill the slot with bitumen.

a. Pour the bitumen around the sensor head and along the length of the slot to the

surface.

b. Add pieces of carton in approximately 1‑meter (3‑foot‑4) intervals to prevent the

bitumen from

flowing freely.

c. Remove the pieces of carton when the bitumen starts curing.

9. (Optional) Spread elastomeric bitumen on top of the construction bitumen.

Overfill the slot to ensure that there are no cracks between the hole and the road or

runway pavement.

10. Ensure that the filling in the hole around the sensor is slanted towards the sensor so

that moisture is able to accumulate on top of the sensor.

This is needed for determining salt concentration.

Chapter 15 – Subsurface Sensor Installation

195

Loading...

Loading...