1-26 SHB WL34 * 2.0

1 Maintenance

Maintenance

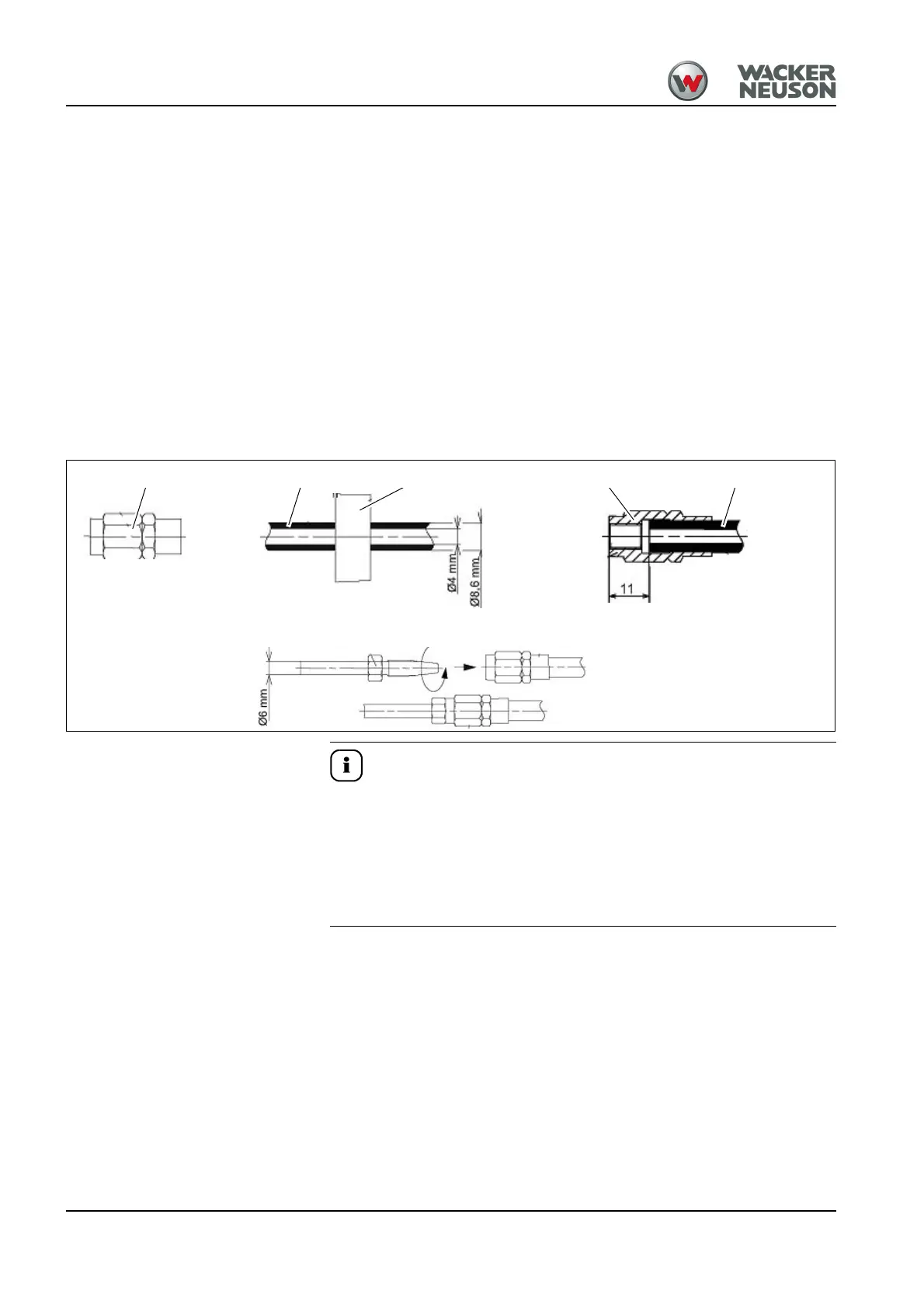

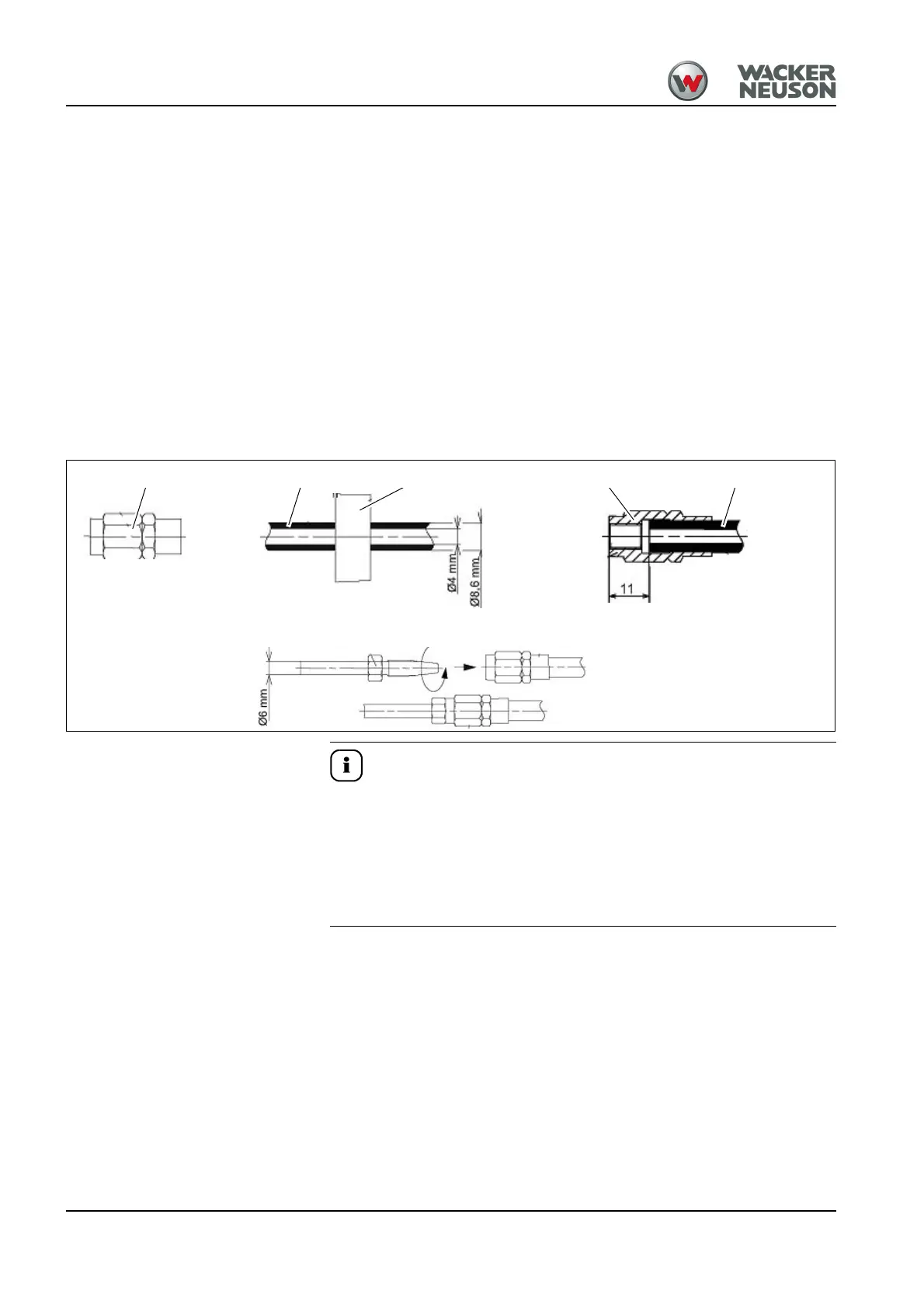

Installing the high-pressure hoses on the central lubrication system

A connection piece and a threaded sleeve at either end of the hose is

required for connecting the high-pressure hose to the distributors.

Installing the threaded sleeve

1. Hold the hose with vise-grip wrenches.

2. Lubricate the end of the hose liberally with grease or oil.

3. Install the threaded sleeve (anticlockwise) on the hose (size 11 mm,

see drawing).

Installing the connection piece

1. Apply oil liberally to the thread and the conical base of the connection

piece.

2. Screw the connection piece into the mounted threaded sleeve as far as

it will go.

For reasons of production tolerances, the hose diameters can differ a little.

If the diameter is smaller, the threaded sleeve can be fitted onto the hose

without applying any force or without turning it.

► Remedy: On the side on which the hose is connected, press the

threaded sleeve about 1 to 2 mm to create an oval shape, so that the

hose is not pressed out as the connection piece is screwed in.

Threaded sleeve High-pressure hose Vise-grip wrenches Threaded sleeve High-pressure hose

Connection piece

Loading...

Loading...