1-22 SHB WL34 * 2.0

1 Maintenance

Maintenance

1.6 Lubrication work

Lubrication

• Park the machine on firm, level and dry ground.

• Secure the machine with the parking brake and wheel chocks.

• Extend and lower the loader unit until all lubrication points can be

accessed from the ground.

• Stop the engine and remove the starting key.

• Operate and remove the battery master switch.

Lubricate the lubrication points every 20 operating hours with water-

resistant multi-purpose grease. Lubricate all other moving parts, such as

the parking-brake lever, pedals (without grease zerks), Bowden cables,

etc. with an oil can.

► Fluids and lubricants on page 1-15.

► Lubrication plan on page 1-13.

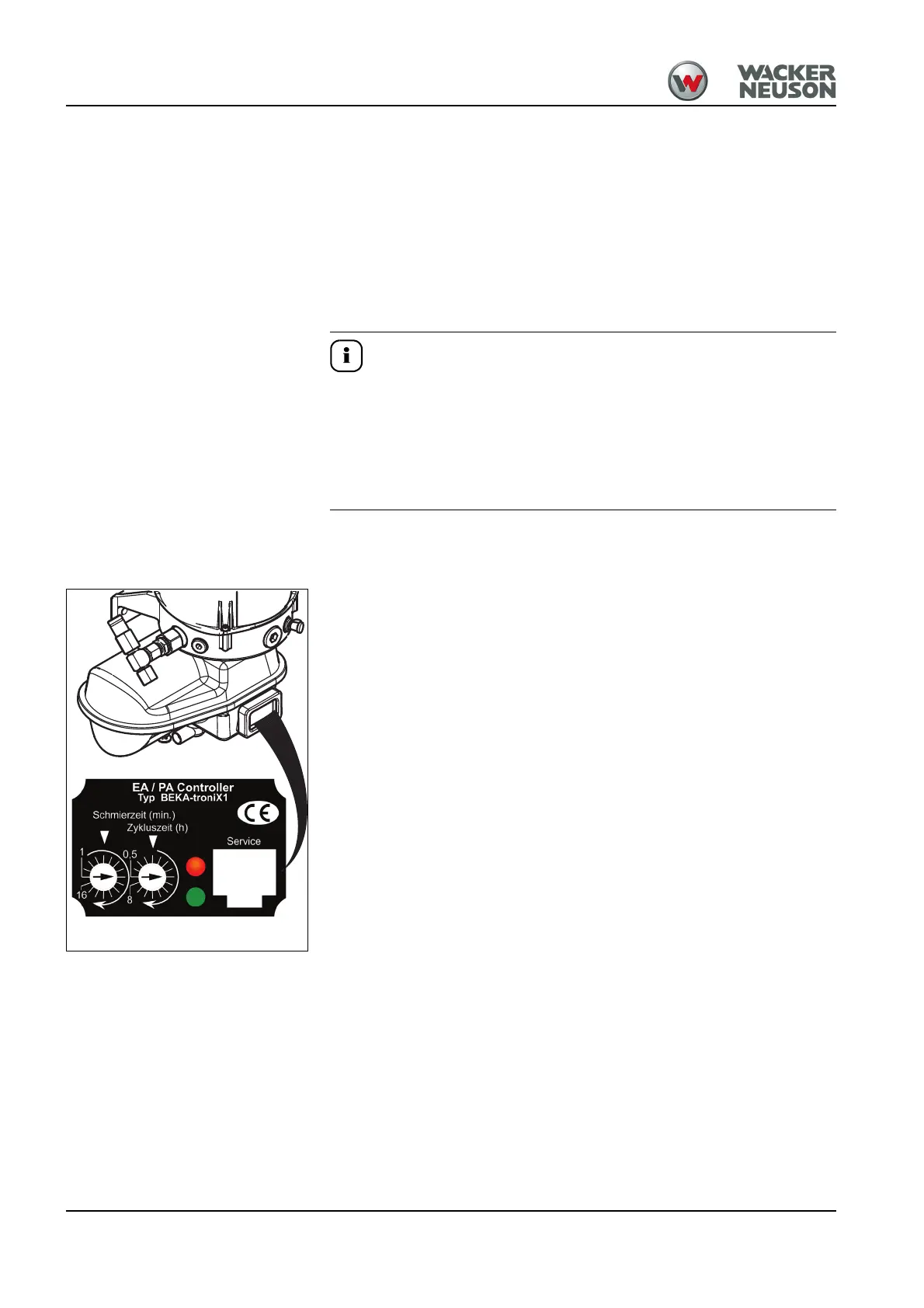

Lubricating with the central lubrication system (option)

Functional description of the central lubrication system

The central lubrication system allows you to lubricate all lubrication points

of the machine in one single step.

• The yellow LED illuminates for 1.5 seconds upon switching on the

starter to indicate functional readiness of the controls (switch-on

check). It stays lit during the entire lubrication procedure.

• The integrated electronic control unit has a data memory for saving the

times that have been set or that have elapsed. The time is taken and

saved if the starter is switched off during lubrication or during a break.

The remaining lubrication time or break time is read from the memory

upon switching the starter on again, and lubrication is resumed where

it was interrupted.

Loading...

Loading...