A20 User Manual (Revision 1.2) Copyright © 2013 Allwinner Technology Co., Ltd. All Rights Reserved. Page 203 / 812

coordinate measurements, with the X and Y plates interchanged. In Single Touch mode, only need to

test X+, Y+ signal. But In Dual Touch mode, it need to test X+, X-,Y+,Y- signal.

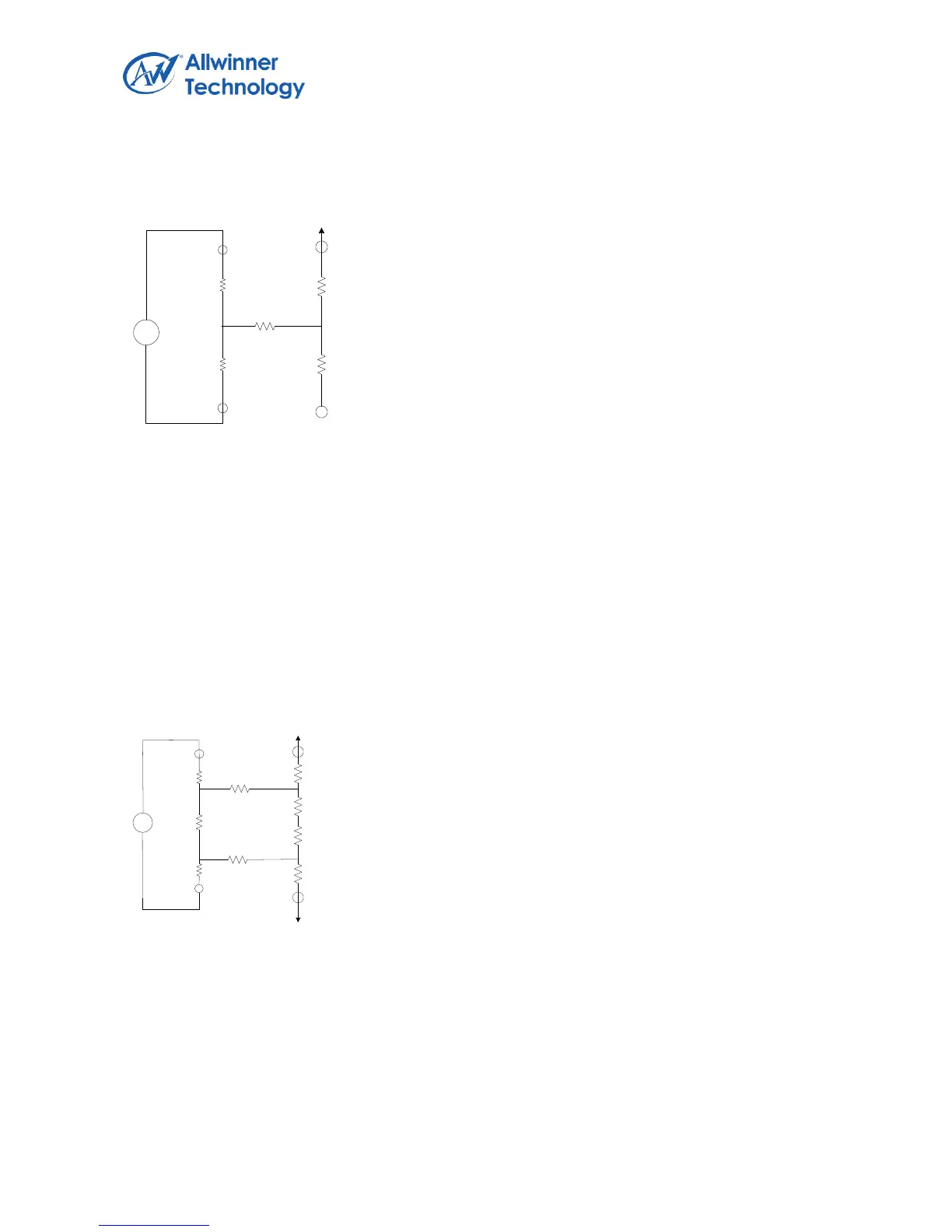

Single Touch X-Position Measurement

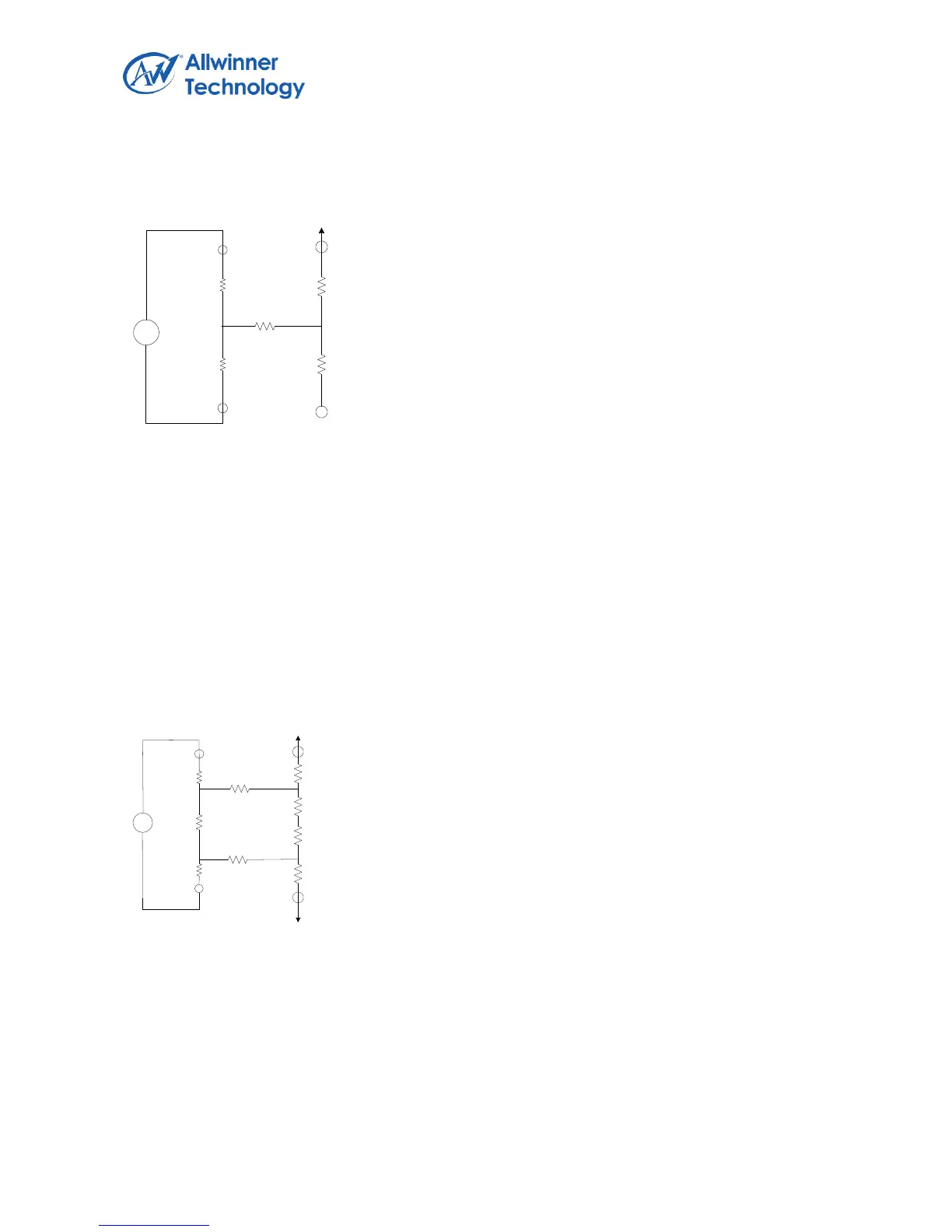

DUAL TOUCH DETECTION

The principle of operation is illustrated below, For an X coordinate measurement, the X+ pin is

internally switched to 3V and X- to GND. The X plate becomes a potential divider, and the voltage at

the point of contact is proportional to its X coordinate. This voltage is measured on the Y+ and Y-,

which carry no current (hence there is no voltage drop in R

Y

+ or R

Y

-). Due to the ratiometric

measurement method, the supply voltage does not affect measurement accuracy. The voltage

references VREF+ and VREF- are taken from after the matrix switches, so that any voltage drop in

these switches has no effect on the ADC measurement. the controller will need to test X+,X-,Y+,Y- ,

and record ΔX=|X+ - X-|, ΔY= | Y+ - Y-|. In practice, we can set a threshold. If ΔX or ΔY greater than

the threshold, we consider it as a dual touch, otherwise as a single touch.

Dual Touch X-Position Measurements

TOUCH-PRESSURE MEASUREMENT

The pressure applied to the touch screen by a pen or finger to filter unavailable can also be

measured by the controller using some simple calculations. The contact resistance between the X

and Y plates is measured, provide a good indication of the size of the depressed area and the applied

pressure. The area of the touch spot t is proportional to the size of the object touching it. And the

Loading...

Loading...