100 CHA NGE PARA METERS

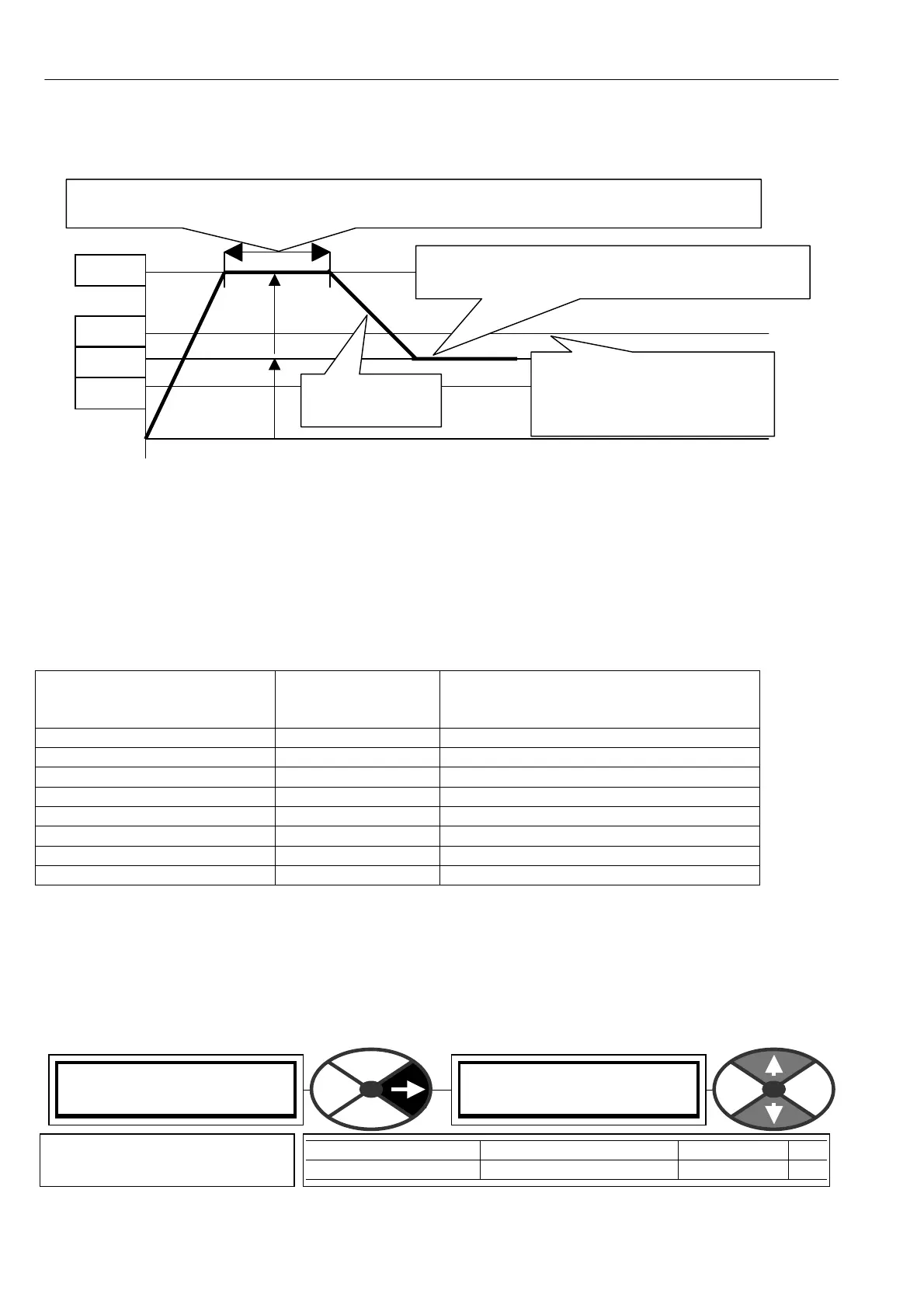

6.8.3.1.2 How to get overloads greater than 150% using 82)O/LO A D % T ARGET

Use this to provide larger overload percentages on motors smaller than the PL/X model rating. This example

sho ws how 82)O/LO AD % T ARGET provides a 200 % overload for a 9 amp motor with a 12 amp PL/X 5.

1) The current set on 2)RATED ARM A MPS (12 amps) represents 100% of the drive (PL/X5), but for this

application must be deliberately set higher than the normal full load motor current (9 amps).

2) The parameter 82)O/LO AD % T ARGET is set at a level equiva lent to the normal full load motor current. (9

amps). Here this is equivalent to 75% of 2)RATED ARM A MPS (12 amps).

3) The 150 % limit (18 amps) is no w double the 82)O/LO AD % T ARGET (75%), which represents a 200%

overload capability with respect to the full load motor current. (9 amps).

AUTOTUNE with 2)RA TED ARM A MPS = 12 A. See 6.8.9 CURRENT C ONTROL / Autotune enable PIN 92.

Set 8.1.8.2 STALL TRIP MENU / Stall current level PIN 179, to a value less than 82)O/LOAD % TARGET.

6.8.3.1.3 Maximum overload table

Table showing maximum overloads according to:- Full load motor current, as a % of 2)RA TED ARM AMPS.

Full load motor current

(82)O/LO A D % TARGET) as

a % of 2)RATED ARM A MPS

Maximum available Maximum overload % available.

(With respect to full load motor current)

100% 150% 150 / 100 = 150%

90% 150% 150 / 90 = 166 %

80% 150% 150 / 80 = 187 %

75% 150% 150 / 75 = 200 %

60% 150% 150 / 60 = 250 %

50% 150% 150 / 50 = 300 %

37.5 % 150% 150 / 3 7.5 = 400%

30% 150% 150 / 30 = 500 %

There are 2 overcurrent trip mechanisms.

1) A soft w are threshold which is set at 300% of 2)RA TED ARM A MPS.

2) A hard w are threshold which activates in excess of 150% of the maximum PL/X model rating.

AUTO TUNE with 2)RA TED ARM A MPS set to its final value. See example above for 9 amp motor.

Set 8.1.8.2 STALL TRIP MENU / Stall current level PIN 179, to a value less than 82)O/LOAD % TARGET.

If 3)C URRENT LIMIT(%) or 82)O/LO A D % T ARGET level is set to 0 %, then no current will flo w .

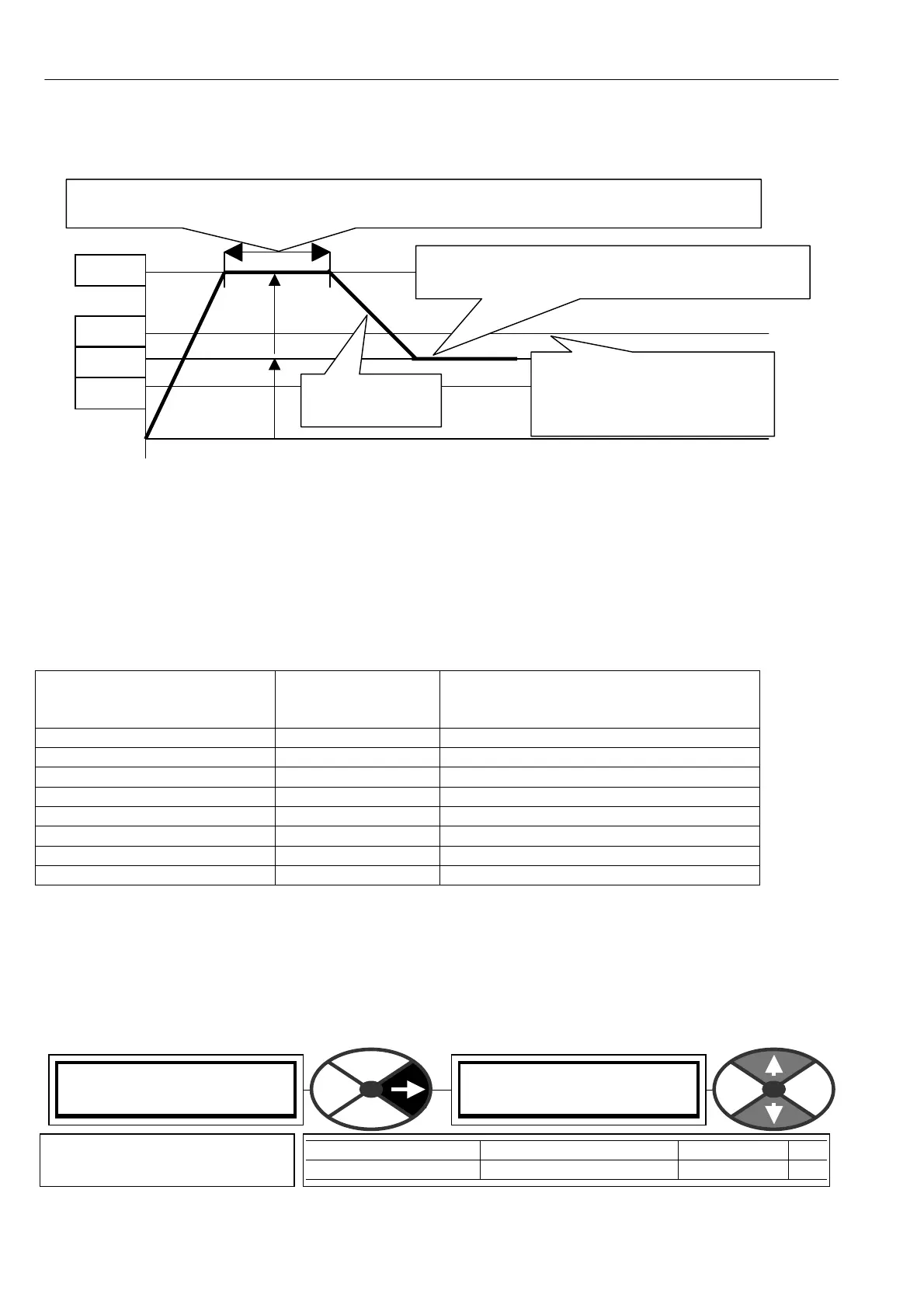

6.8.3.2 CURRENT O VERLO AD / Overload ramp time PIN 83

E.g. For Limit = 150 %, time = 20 secs, target = 105 %. Then ramp time to target = 9 secs (ie.45% of 20 secs).

CURRENT O VERLO A D 4

83)O/LO A D RA MP TIME

83)O/LO A D RA MP TIME

20.0 SECS

PARA METER RANGE DEF AULT PIN

O/LOAD RA MP TIME 0.1 to 20.0 secs 20.0secs 83

Sets the time taken to reduce

the current limit by 100%

150%

100%

50%

82)O/LO A D % T ARGET set to 75.00%. Eg. Limits

at 9 amps with 2)RA TED ARM AMPS = 12 amps

With Iarm = 150 %. The 1 50 % limit is available for 25 secs prior to commencing reduction.

E

for PL/X5, 150% = 1 8 am

s. (For a motor rated at 9 am

s, this re

resents 200 %).

75%

83)O/LO A D

RA MP TIME

2)RA TED ARM A MPS.

Eg for PL/X 5 set to 12 amps

Equivalent to PL/X 100 %.

(133% of full load motor current)

Loading...

Loading...