CHA NGE PARA METERS 117

To summarise.

The orientation function is activated by dropping belo w the zero speed threshold. 24 1)M ARKER OFFSET is

actioned only once at the commencement of orientation, and 242)POSITION REF is then follo w ed with

respect to the 241)MARKER OFFSET position. The orientation function is de-activated by increasing the

speed demand above the zero speed threshold.

242)POSITIO N REF may be changed as many times as required and the shaft position will track it relative to

the 241)M ARKER O FFSET position. Each time 242)POSITION REF is changed to a ne w value, the 244)IN

POSTION FLAG may be used to determine when the ne w position has been achieved.

The gain and hence response of the position control loop is set by 122)ZERO SPEED LOCK. A value of zero

will turn off the position loop. The block also provides 243)M ARKER FREQ MO N giving marker frequency.

For systems that require position locking at zero speed but the absolute position is not important, then

122)ZERO SPEED LO CK only may be used. In this case no marker is required, and the 240)M ARKER EN ABLE

input should be set to disabled.

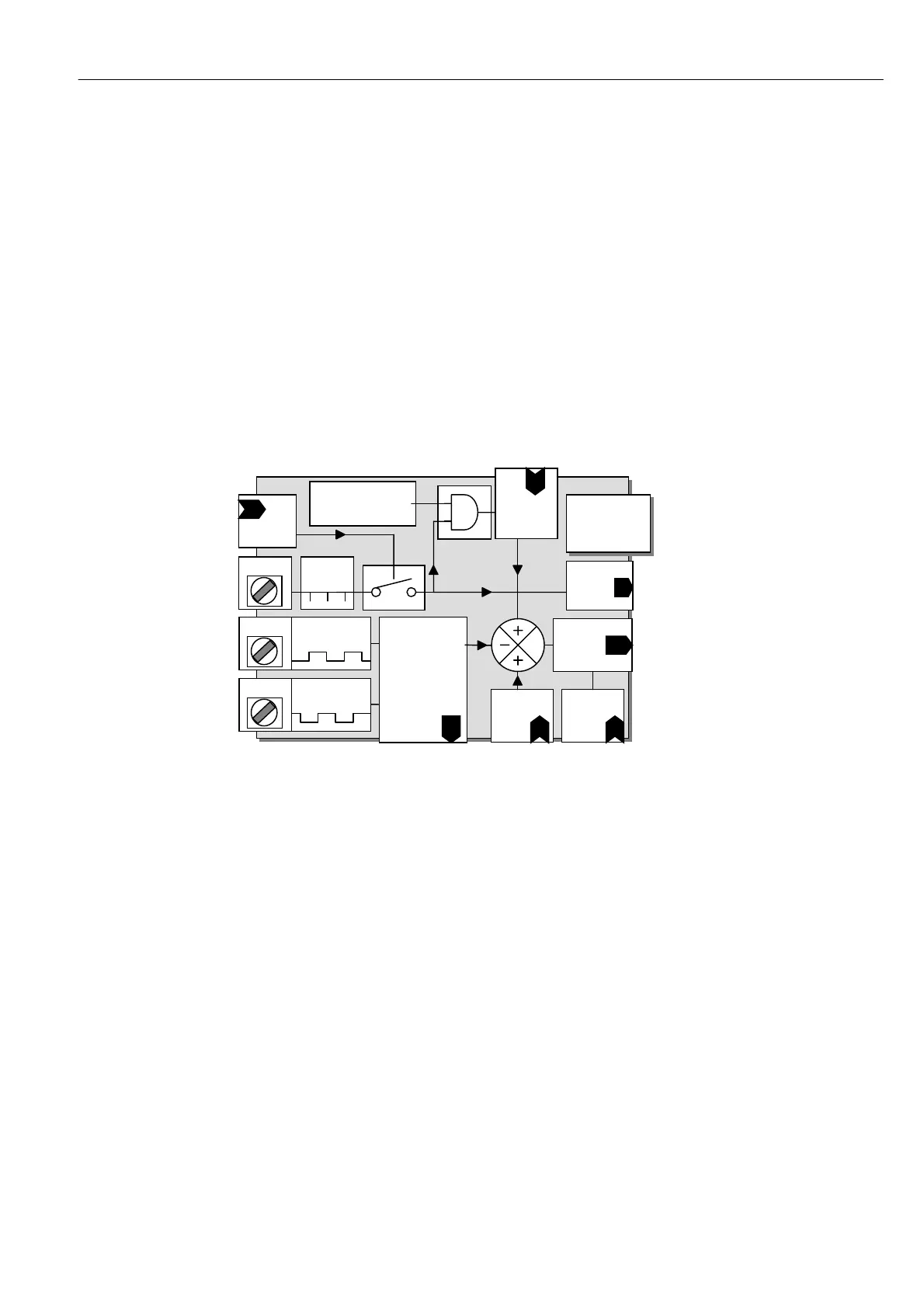

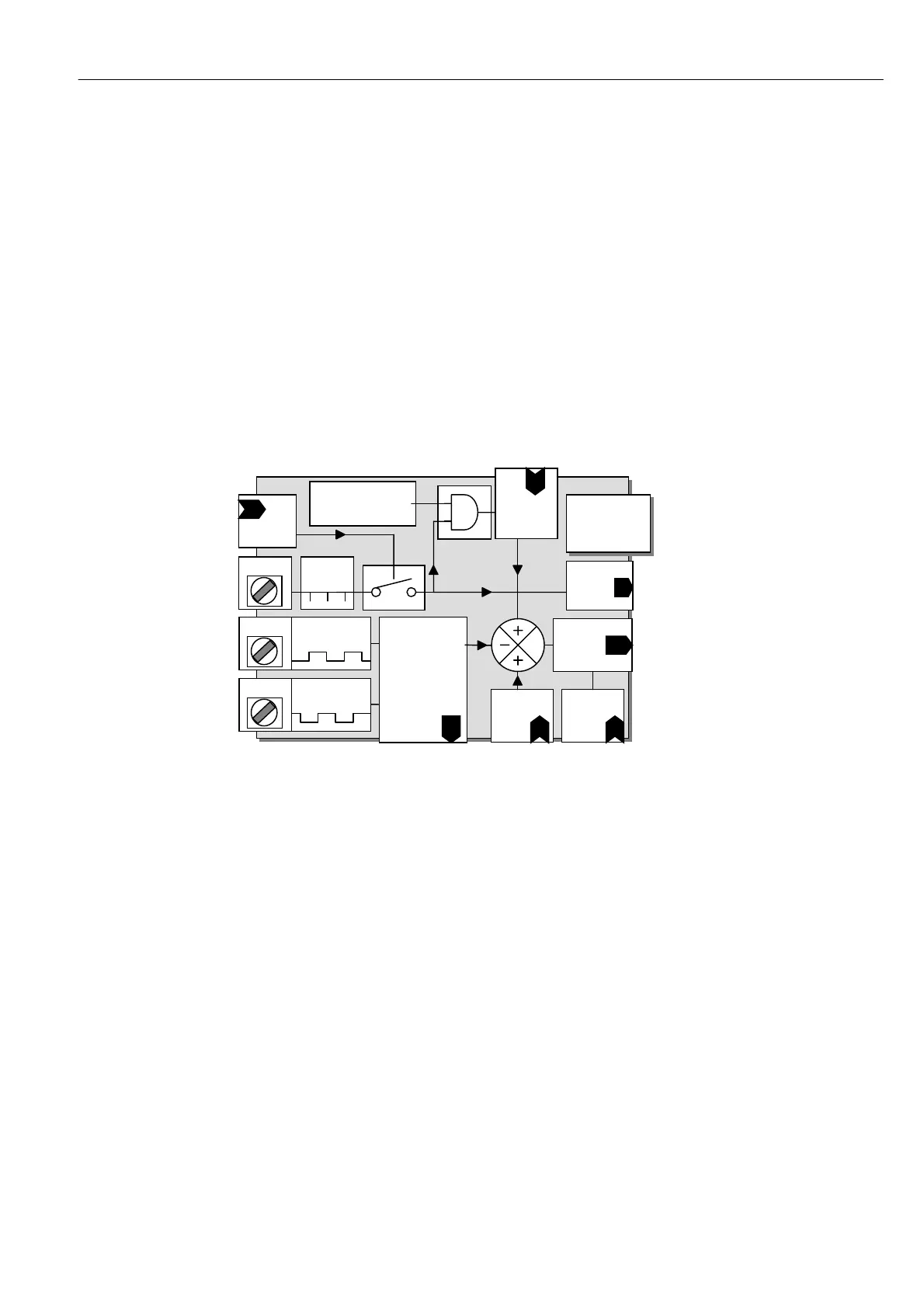

6.10.9.1 SPINDLE ORIENT A TE / Block diagram

6.10.9.1.1 Spindle orientate operation

For all speeds above 117)ZERO INTLK SPD %, the spindle orientate control action is disabled. However the

marker frequency monitor will function within its defined limits providing 2 40)M ARKER EN ABLE is enabled.

Note. The marker that is used for orientation is the la st one to be input prior to the spe ed falling below

117)ZERO INTLK SPD % threshold. ( This is normally within 1 revolution of the shaft prior to the threshold).

When the speed falls below 117)ZERO INTLK SPD %, then the spindle orientate function will operate

providing 122)ZERO SPEED LO CK is set to a non-zero value and 240)M ARKER ENABLE is enabled. Once the

block has commenced functioning, it will continue as long as the speed demand is below 117)ZERO INTLK

SPD %. The actual speed may exceed 117)ZERO IN TLK SPD % without turning the block off.

The sequence of operation is as follows.

1) Speed demand and feedback fall and remain below 117)ZERO INTLK SPD % for 400mS. (Includes

Stopping sequences using terminals T33 or T32). (*PL models can only orientate when stopping).

2) Spindle orientation block is activated.

3) The shaft position at the last marker to be input prior to the speed falling below 117)ZERO IN TLK SPD %

is calculated by the PL/X.

4) The shaft seeks the 241)M ARKER O FFSET position.

5) As the shaft approaches the marker offset positi on the block checks for the 242)POSITION REF target.

SPINDLE

ORIENT ATE

PIN 242

Position

Ref

BIDIREC TION AL

PULSE C OUNTER

Shaft position

feedback count

PIN 24 4

IN Position

FLA G

PIN

24 1

M ARKER

OFFSET

(One shot)

Output

To

position

Control loop

T 1 5

T 15

M ARK

PULSE

Below Zero Interlock

Speed % (PIN 11 7)

Threshold

Terminal 1 6

FB PULSE B

T 1 6

Terminal 1 7

FB PULSE A

T 1 7

PIN 243

Marker

Freq OP

PIN

240

Marker

Enable

PIN 122

ZERO

SPEED

LO C K

Loading...

Loading...