CHA NGE PARA METERS 107

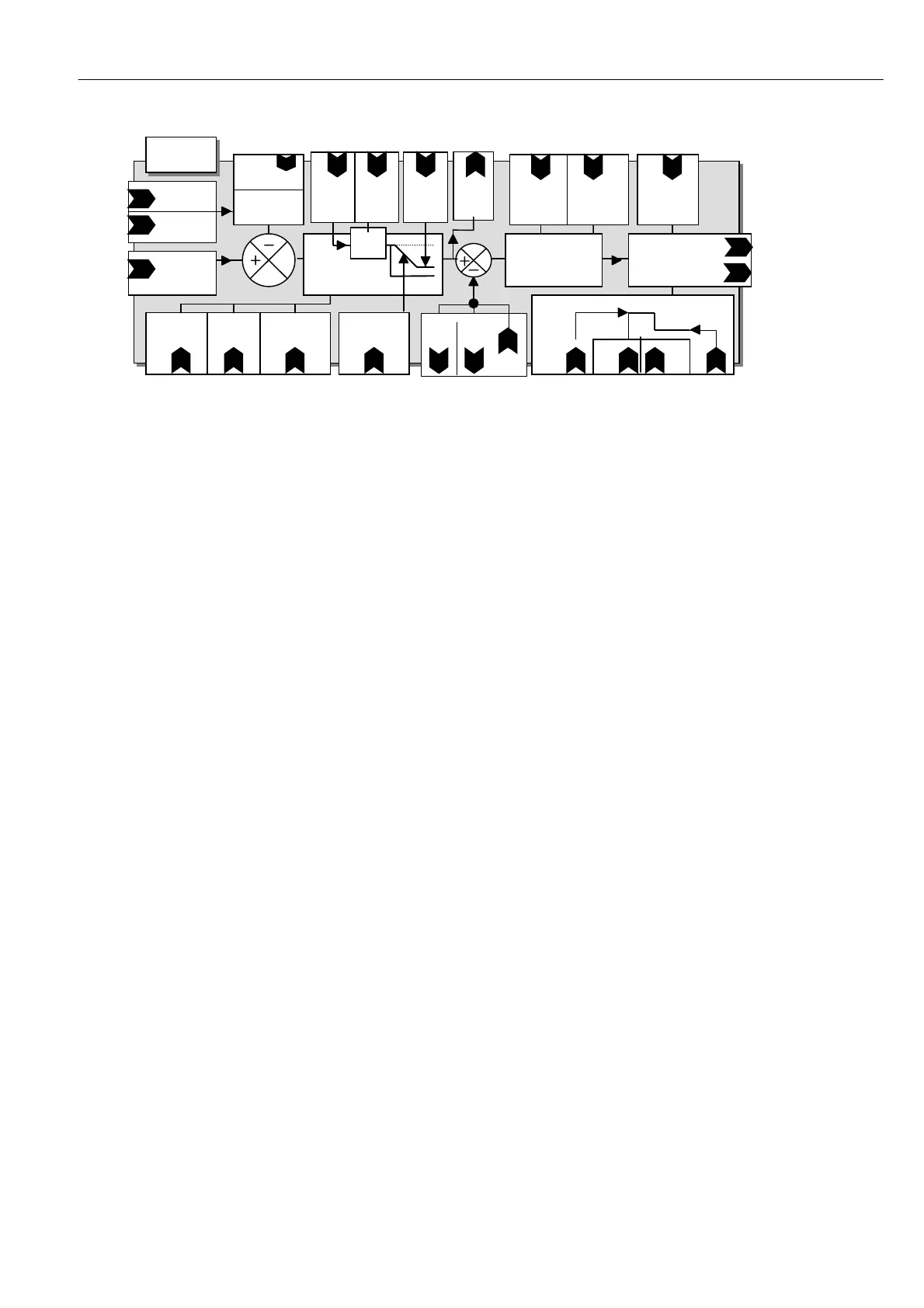

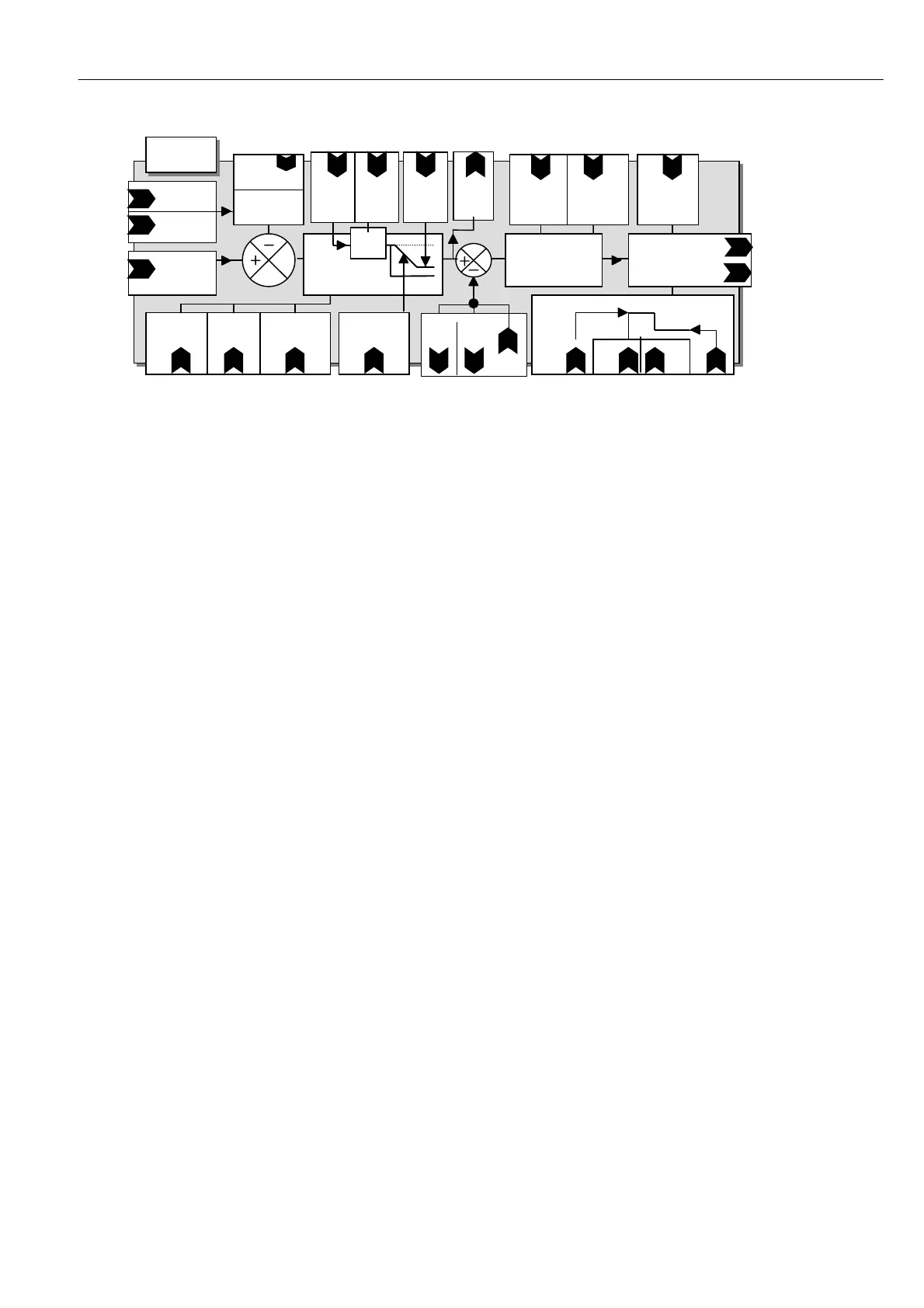

6.9.1 FIELD CONTROL / Block diagram

1) Voltage output clamp. This is an open loop setting of the field bridge-firing angle allo wing the DC

output voltage to be set bet w een 0 to 90% of the incoming supply voltage. E. g. for an A C supply of 400 V

the 90% output voltage is 3 60 V D C. Note if the A C supply varies, then the field output voltage will vary in

proportion. Also if the field resistance changes then the resulting output current will change.

If you know the rated field voltage, you can set 100)FIELD VOLTS OP % clamp parameter value in this

menu. Adjust the field output voltage to the dataplate value, as a % of the applied AC supply.

Note. Please ensure that 4)RA TED FIELD A MPS is sufficiently high to force the 100)FIELD V OLTS OP %

clamp into operation, at the desired voltage, under all conditions.

4)RA TED FIELD A MPS, scaled by 114)FIELD REFERENCE, sets the demand for the field current control loop

and 100)FIELD V OLTS OP % operates as a clamp on the field bridge firing angle.

If the current demand is satisfied at a voltage output belo w the clamp level, then the current loop will prevail.

2) Current control. The range of output voltage is the same in this mode as in the voltage output clamp

mode, ho wever the control loop operates on the actual current flowing in the field and w orks to maintain this

at the desired value. Providing that the output voltage is not clamped by the 90% natural limit, or by

100)FIELD V OLTS OP %, and is able to move around, then the current delivered will al ways be controlled

irrespective of supply and resistance changes. This is the preferred control strategy.

Hence it is possible to operate with the field current control prevailing and the voltage % a s a higher safety

clamp, or the voltage % clamp prevailing and the field current control as a higher safety level.

The back emf of a motor is a good linear representation of its speed. This is significantly improved if the field

current and hence flux is kept constant. Hence with the field in current control mode, A V F speed control

accuracy is improved. It is good practice in control engineering to minimise the error correction requirements

of any loop, hence having a current controlled field is also recommended when using a tachogenerator.

Field weakening in current mode is required where the speed of the motor exceeds its base speed. The field

current is held at its rated value until the armature voltage reaches its spillover value. Reducing the field

current, rather than increasing the armature voltage, then satisfies any further increase in speed demand.

Further consideration must be given to the field quenching modes. If dynamic braking is required then the

field must be maintained after the drive armature output is halted. Without the field, the motor would not be

able to act as a generator and dissipate its rotational energy into the braking resistor.

When motors are standing still for extended periods it is useful to apply a reduced field current to prevent

overheating, save energy and in cold climates prevent condensation or freezing.

For any non running mode the field will be quenched. If the RUN input goes lo w at any point during the

stopping process, either heading for zero speed or during the delay period, then the contactor will drop out

straight away and the field quenched. The quenched condition is determined by 111)STA NDBY FIELD ENBL,

112)ST A NDBY FLD CUR and 113)FLD Q UENCH DELA Y.

See also 14.9.1 Wiring diagram for A C supply to L1/2/3 different to EL1/2/3. (E.g. Low voltage field)

PIN 101

Prop

Gain

PIN 102

Integral

Gain

Field angle of advance

Monitor

PIN 146

Field active monitor

PIN 14 7

PIN 9 9

Field

enable

Field Current

error amp

P + I

PIN 104

Fld w k Prop

Gain

PIN 105

Fld w k Int

T C ms

PIN 106

Fld w k deriv

TC ms

PIN 107

Fld wk Fb D

PIN 108

Fld wk Fb I

FROM

Arm Voltage

Feedback

SIGNAL

conditi oning

Weakening

Enable

PIN 10 3

Field

w eakening

PID Speed

PIN 109

Spillover %

Max Arm V oltage

Field dela y and quench PIN

PIN 11 2

100 Standby current

Volts%

OP Clamp Quench Del Standby En

PIN PIN

113 1 11

PIN

11 0

Min

Field

10 0 %

Field

(from

PIN 4)

PIN

14 3

field

dem

FIELD

CO NTROL

% A A MPS

PIN PIN

14 4 145

I

fld fb

PIN

11 4

Field

Re f

X

Loading...

Loading...