106 CHA NGE PARA METERS

6.9 CHANGE PARAMETERS / FIELD CONTROL

PIN number range 99-114

The field controller within the PL/X consists of a

single phase half controlled thyristor bridge with a

fly wheel diode. The A C supply to the bridge is

delivered through terminals EL2 and EL3, and the

rectified output is on terminals F + and F-. The

supply can be any w here in the range of 100 to

480V A C, but must, at least, be 1.1 times the

maximum field output voltage you require.

Note that the supply to EL2 and EL3 is also utilised

to determine phase rotation of the local supply.

The purpose of the field winding in a motor is to

provide flux that intersects the armature windings.

The flux generated is a function of the CURRENT

flo wing in the field coils. When considering the set

up of the field output you are able to use 1 of 2

types of control strategy.

1) Voltage clamp with higher current limit

protection.

2) Current control with higher voltage clamp

protection.

Motor field windings are normally very inductive and

have a long time constant. This results in smooth

current in the field. In this case the field current

reading is reasonably accurate irrespective of when

it is sampled.

Some motors have shorter field winding time constants than normal resulting in up to 20 % ripple. In this

case the PL/X may sample the current at a non-ideal point in the cycle which will result in a slightly incorrect

control level. (Usually no more than a few %) To normalise the field current back to its correct level it may be

necessary to use the field current trim. See 6.1.12 C ALIBRA TION / Field current feedback trim PIN 15, or

re-calibrate the field current to overcome the inaccuracy.

Warning. Field reversal or disconnection.

Due to the high inductance of motor fields it may take several seconds for the field current to decay to zero

after the field output has been inhibited by the PL/X. Do not open circuit the fiel d unless the field curr ent has

reached zero. The PL/X is unable to measure the decaying current after an inhibit, so it is not possible to use

the field current monitors or field active flag to show zero current has actually been attained. It is necessary

to observe the current on an external instrument and time how long it takes to decay. The interval timer

block may then be utilised to implement a safety delay before opening the fiel d circuit.

Failure to observe this w arning may cause flashover of the field circuit and result in damage to the system.

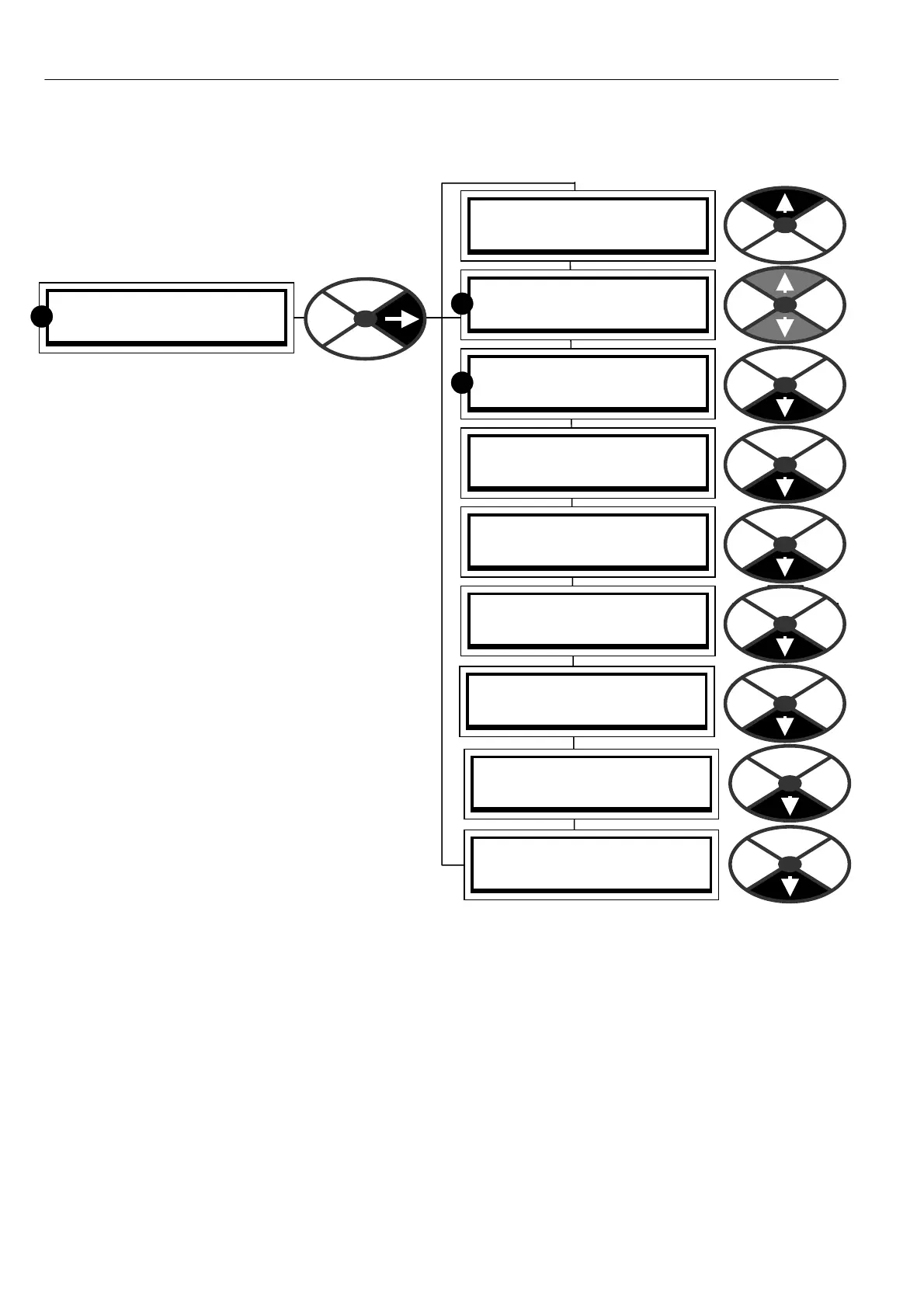

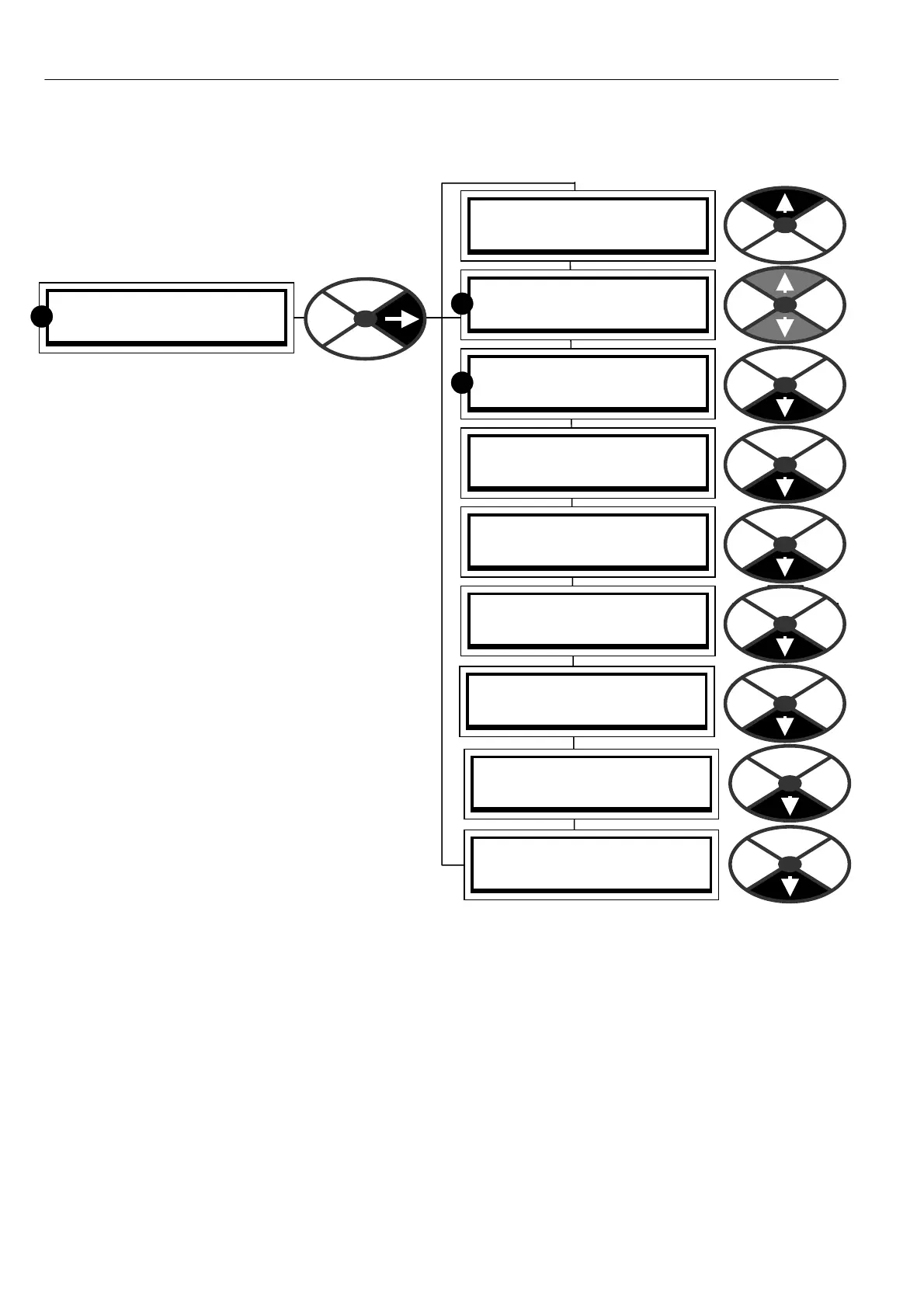

CH A NGE PARA METERS 2

FIELD C ONTROL 3

R

FIELD C ONTROL 3

114)FIELD REFERENCE

FIELD C ONTROL 3

99)FIELD EN ABLE

FIELD C ONTROL 3

FLD WE A KENING MENU 4

FIELD C ONTROL 3

100)FIELD V OLTS OP %

FIELD C ONTROL 3

101)FIELD PROP G AIN

FIELD C ONTROL 3

102)FIELD INT G AIN

FIELD C ONTROL 3

111)ST A NDBY FLD ENBL

R

R

FIELD C ONTROL 3

112)ST A NDBY FLD CUR

FIELD C ONTROL 3

113)FLD Q UEN CH DELA Y

Loading...

Loading...