68 CHA NGE PARA METERS

6.1.11 C ALIBRA TION / IR compensation PIN 14

This parameter is used when armature voltage speed feedback type is selected or in field weakening mode.

Note. Speed is proportional to the back EMF of the motor. Back EMF = A VF – IR drop.

Hence when the armature current is high the IR drop is high. At zero armature current the IR drop is zero.

To set this parameter with A VF feedback, arrange if possible to apply a significant load change to the

system. Slowly increment the parameter until the load change has minimum effect on the speed holding.

Alternatively calculate the parameter using the formula belo w and initially enter this value.

IR C OMPENS ATION (%) = RA TED MOT OR A MPS X Armature resistance X 100 / RA TED ARM V OLTS.

Note. Excessive compensation may lead to instability.

See also 6.9.6 FIELD CONTROL / FLD WEA KENING MENU for field w eakening systems.

6.1.12 C ALIBRA TIO N / Field current feedback trim PIN 15

This trim factor may be applied during drive running. The factor is al ways greater than unity hence can only

increase the strength of the feedback. The closed loop system then receives feedback that is too high and

causes a reduction of the controlled field current.

(This trim is useful if the precise 4)RA TED FIELD A MPS calibration parameter is not exactly known and must

be discovered during running by starting with a higher than expected value. Once the correct level of

feedback has been determined using this trim (the DIAGNOSTICS menu can be used to monitor actual levels

of feedback), it can then be entered in the 4)RATED FIELD AMPS calibration parameter. This trim may then

be returned to 1.000).

6.1.13 C ALIBRA TION / Armature volts trim PIN 16

This trim factor may be applied during drive running. The factor is al ways greater than unity hence can only

increase the strength of the feedback. The closed loop system then receives feedback that is too high and

causes a reduction of the armature voltage feedback and hence a reduction in speed.

(This trim is useful if the precise 18)RA TED ARM V OLTS calibration parameter is not exactly known and

must be discovered during running by starting with a higher than expected value. Once the correct level of

feedback has been determined using this trim, (the DIA GNOSTICS menu can be used to monitor actual levels

of feedback), it can then be entered in the 18)RATED ARM V OLTS calibration parameter. This trim may then

be returned to 1.000).

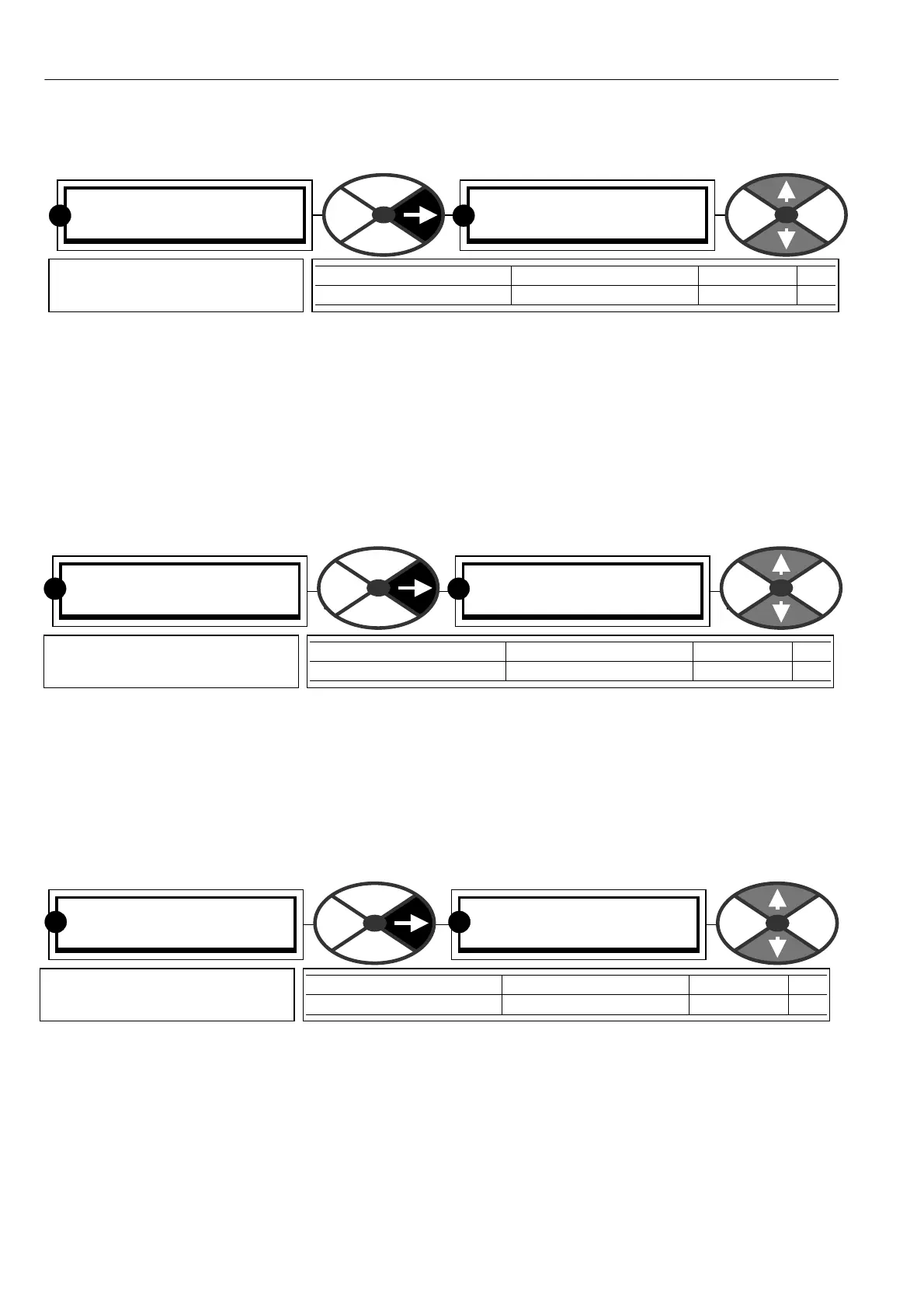

C ALIBRA TIO N 3

14)IR COMPENS A TION

14)IR COMPENS A TION

0.00 %

PARA METER RANGE DEFAULT PIN

IR C OMPENS ATION 0.00 to 100.00% 0.00 % 14

Sets % compensation of the

A V F signal due to IR drop

RR

C ALIBRA TIO N 3

15)FIELD CUR FB TRIM

15)FIELD CUR FB TRIM

1.0000

PARA METER RANGE DEFAULT PIN

FIELD CUR FB TRIM 1.0000 to 1.1 00 0 1.0000 15

Sets a positive trim factor for

the field current feedback

R

R

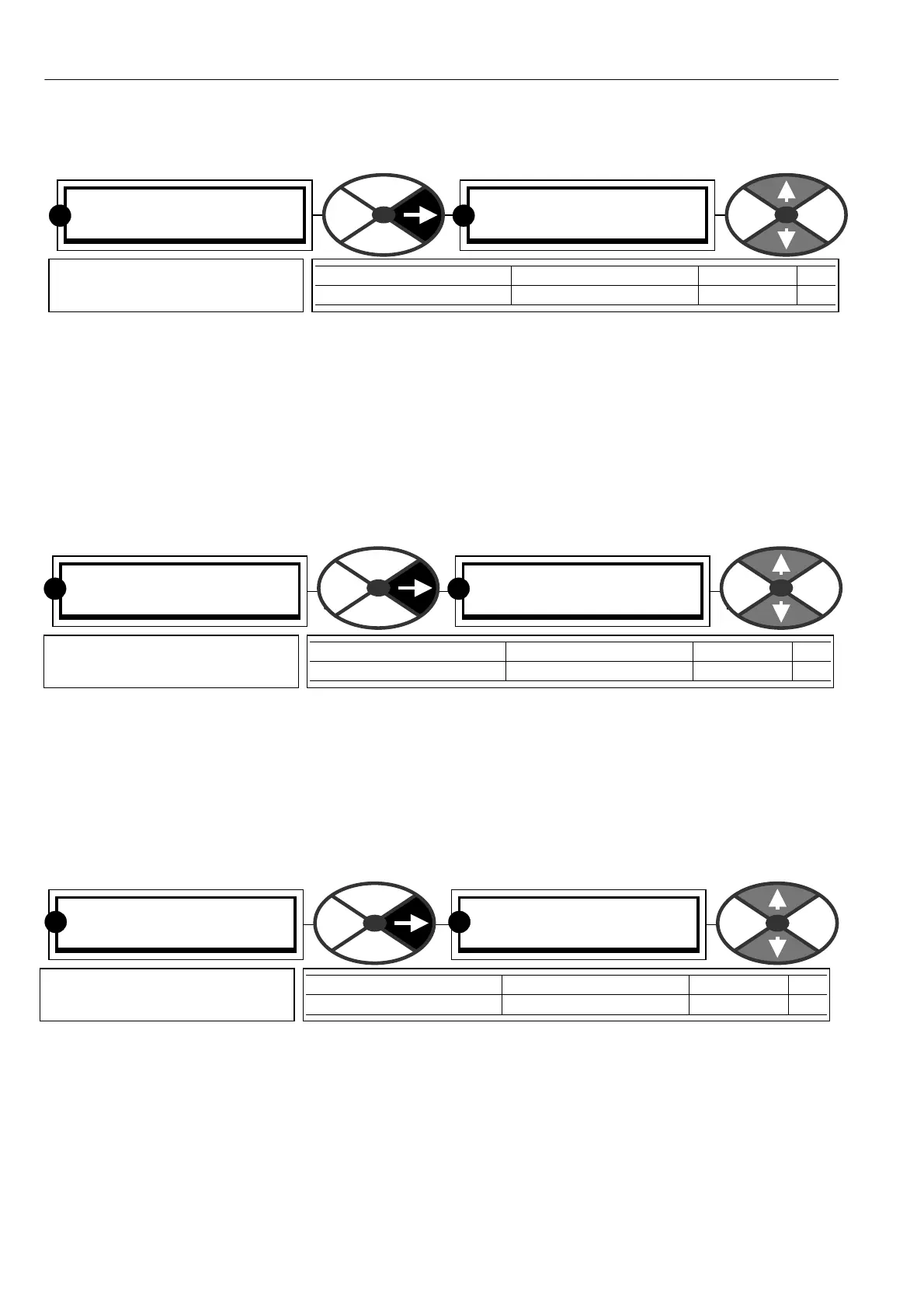

C ALIBRA TIO N 3

16)ARM V OLTS TRIM

16)ARM V OLTS TRIM

1.0000

PARA METER RANGE DEFAULT PIN

ARM V OLTS TRIM 1.0000 to 1.1000 1.000 0 16

Sets a positive trim factor for

the armature volts feedback

RR

Loading...

Loading...