CHA NGE PARA METERS 63

6.1.8 C ALIBRA TION / Max tacho volts PIN 8

Multiply the output volts per rev value for the tacho by the full speed rpm of the tacho

e. g. 1 tacho rating = 0.0 6 V per rev, 10 0% speed of tacho = 500 rpm, then tacho scaling = 30.00 V

e. g. 2 tacho rating = 0.0 9 V per rev, 10 0% speed of tacho = 2000 rpm, then tacho scaling = 180.00V

Alternatively, for systems NOT employing field w eakening, run the system in A VF at desired full speed and

monitor the tacho volts. See 7.1.7 SPEED LOOP MONITOR / Tachogenerator volts monitor PIN 129, then

after entering the observed full speed tacho volts, convert to tacho feedback. See 3.4.4 Analogue

tachogenerator input, also 6.1.9 C ALIBRA TIO N / Speed feedback type PIN 9 QUICK ST ART.

The sign of the parameter should correspond to the sign of the tacho volts for positive speed demand.

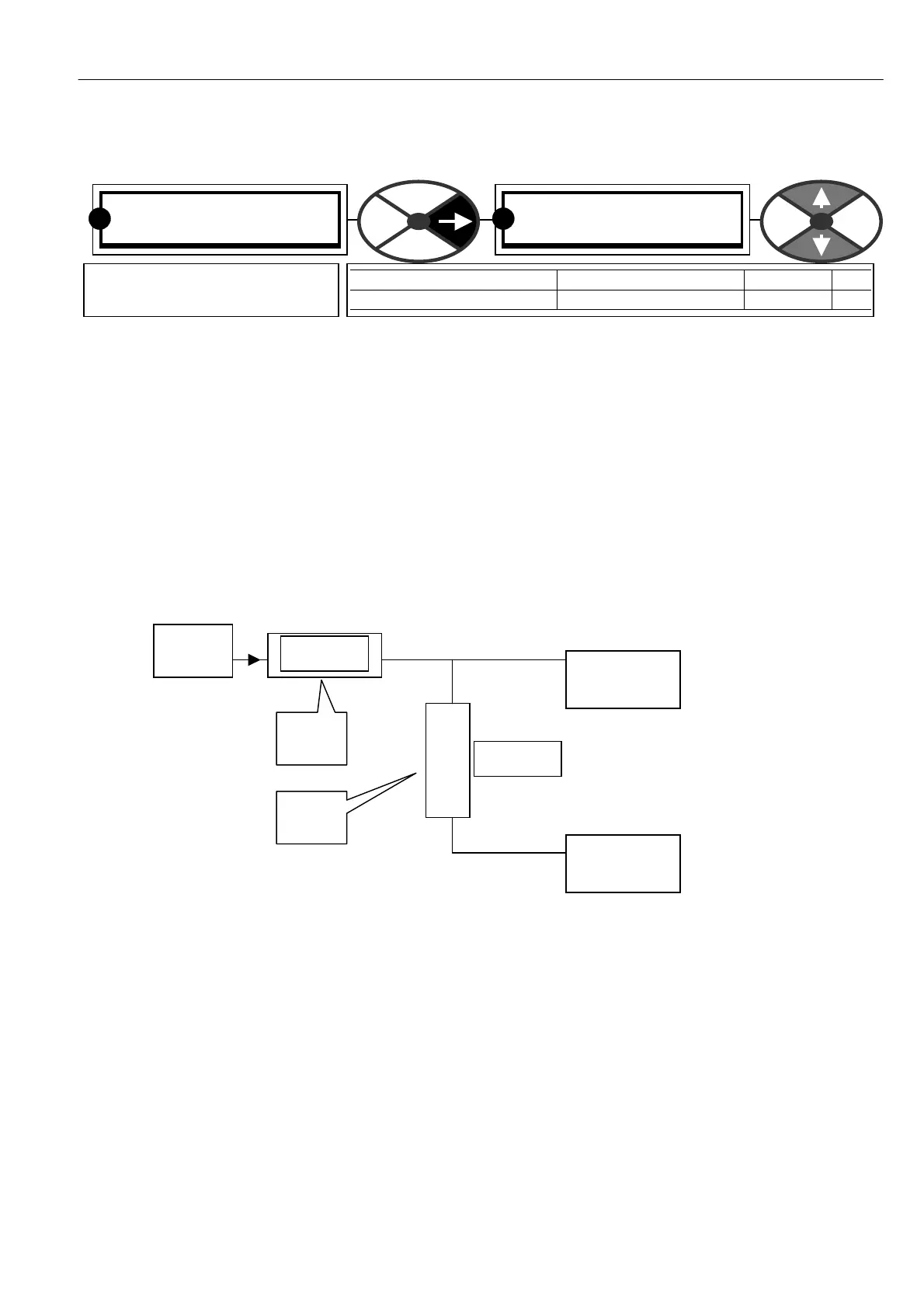

For tacho volts which exceed 200V full scale, it is necessary to provide an external resistor dropper network

as follows.

The network sho wn will allo w full scale voltages up to 40 0 Volts. The number scrolled in the window should

be set to half the full scale tacho volts. Appropriate measures must be taken to dissipate the heat from the

dropper resistors. The total po w er in watts dissipated will be (Tacho signal volts)

2

/ 20,000.

There is a tacho failure detection system that may be configured to either trip the drive, or automatically

switch to A VF. See 8.1.1 MOT OR DRIVE ALARMS / Speed feedback mismatch trip enable PIN 171.

See also 3.4.4 Analogue tachogenerator input.

10K

5W

10K

5W

Tacho

signal

Terminal 2 6

T A CHO

Terminal 2 5

0V

Resistor

Resistor

C ALIBRA TIO N 3

8)M A X T A CHO V OLTS

8)M A X T A CHO V OLTS

60.00V

PARA METER RANGE DEF AULT PIN

M A X T A CH O V OLTS + /-200.00 volts 60.0 0V 8

Scales the tacho input for full

feedback volts at 100 % speed

R R

Loading...

Loading...