Basic application 43

4.5.2 Quick start calibration step by step

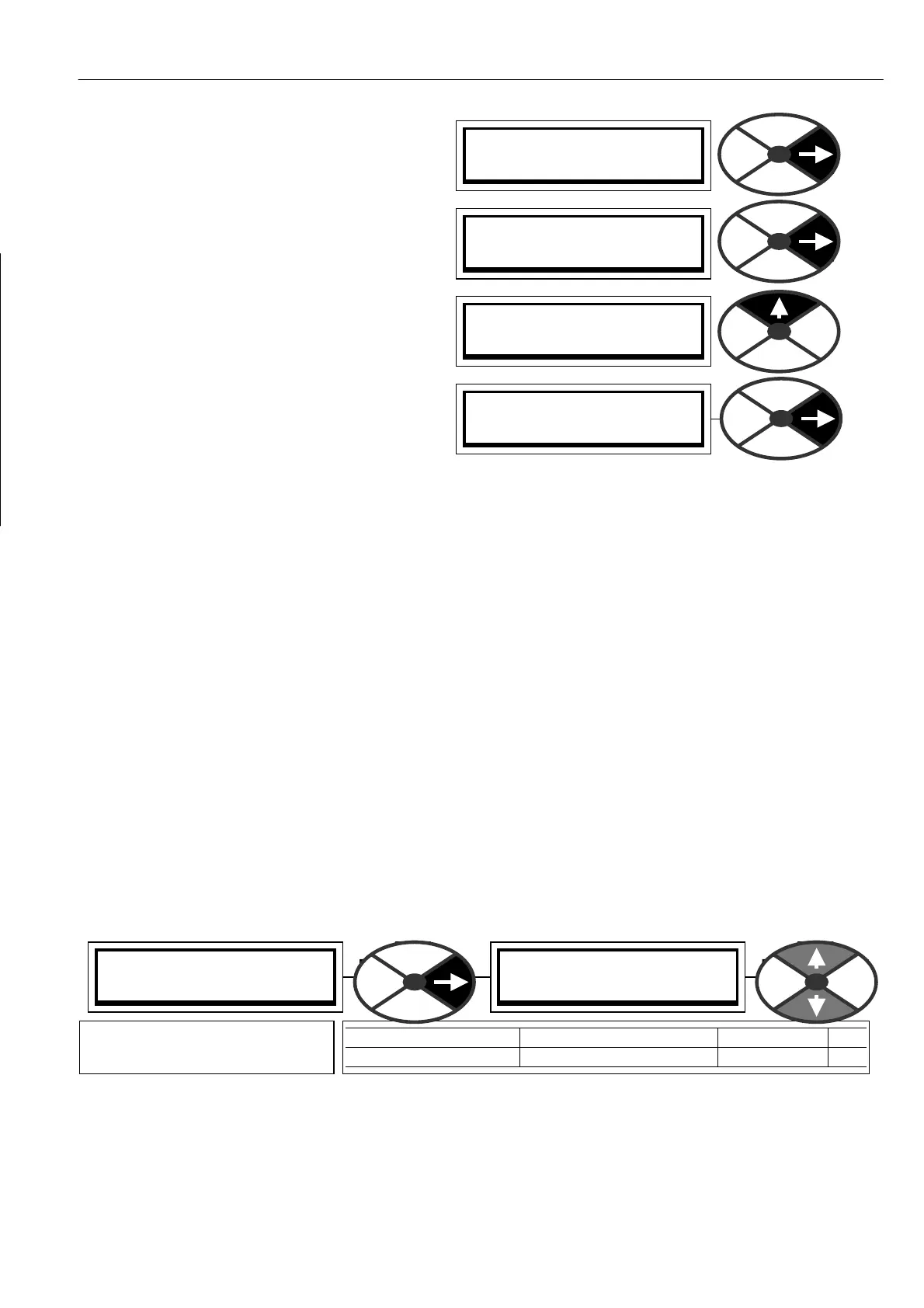

1) Turn on the control supply and press the right

key to exit diagnostics for the ENTRY MENU.

2) Press the right key to enter the ENTRY MENU

/ CH A NGE PARAMETERS window . Press the

right key again to enter the CH A NGE

PARA METERS / RUN MODE RA MPS menu. Then

press the up key for the CHAN GE PARAMETERS

/ C ALIBRA TION menu. Enter the CALIBRATIO N

menu by pressing the right key. Once there, use

the up or down key to travel round the circular

menu.)

3) Only 8 of the available parameters need to be

adjusted for Q UICK ST ART. (PINs 2, 3, 4, 5, 6,

9, 18, 19). Skip the other windo ws.

4) Select the quick start parameters by using the up / down keys. Press the right key to enter the parameter

adjustment window for each in turn. Modify each one to suit your system using the up/dow n keys. Use the

left key to back out of each parameter adjustment window and return to the circular C ALIBRATION menu.

When you have finished modifying the 8 quick start parameters, it is time to save the changes you have

made. Use the left key to return to the ENTRY MENU / CHANGE PARAMETERS menu. Use the up key to

arrive at ENTRY MENU / PARA METER S A VE. Use the right key to enter the PARA METER SA VE windo w . Use

the up key to save the parameters. While the save is taking place the bottom line will read SA VING. When

the save is complete the bottom line will read FINISHED. You can now return by holding do wn the left key.

This will take you to the default diagnostics, and then one tap right to the ENTRY MENU.

Note. For a description of the default diagnostics see 5.1.6 Default % DIA GN OSTIC summary windo ws.

Now the PL/X is calibrated to match your motor it is time to apply 3 phase po w er for the first time to

establish correct functioning of the main contactor and that the field current is correct. Remember that there

should be a fire-bar inserted in the armature circuit to protect against fault currents.

See 4.2 Main Contactor operation and 7.3 DIA GNO STICS / FLD I LOOP MONITOR.

Once you have established correct functioning of the main contactor and that the armature and field are

receiving po wer as expected, then you must remove the fire bar in readiness for the quick start procedure.

4.5.3 Quick start current loop AUTOTUNE

5) The next step is to set up the armature current loop response. The unit is provided with an autotune

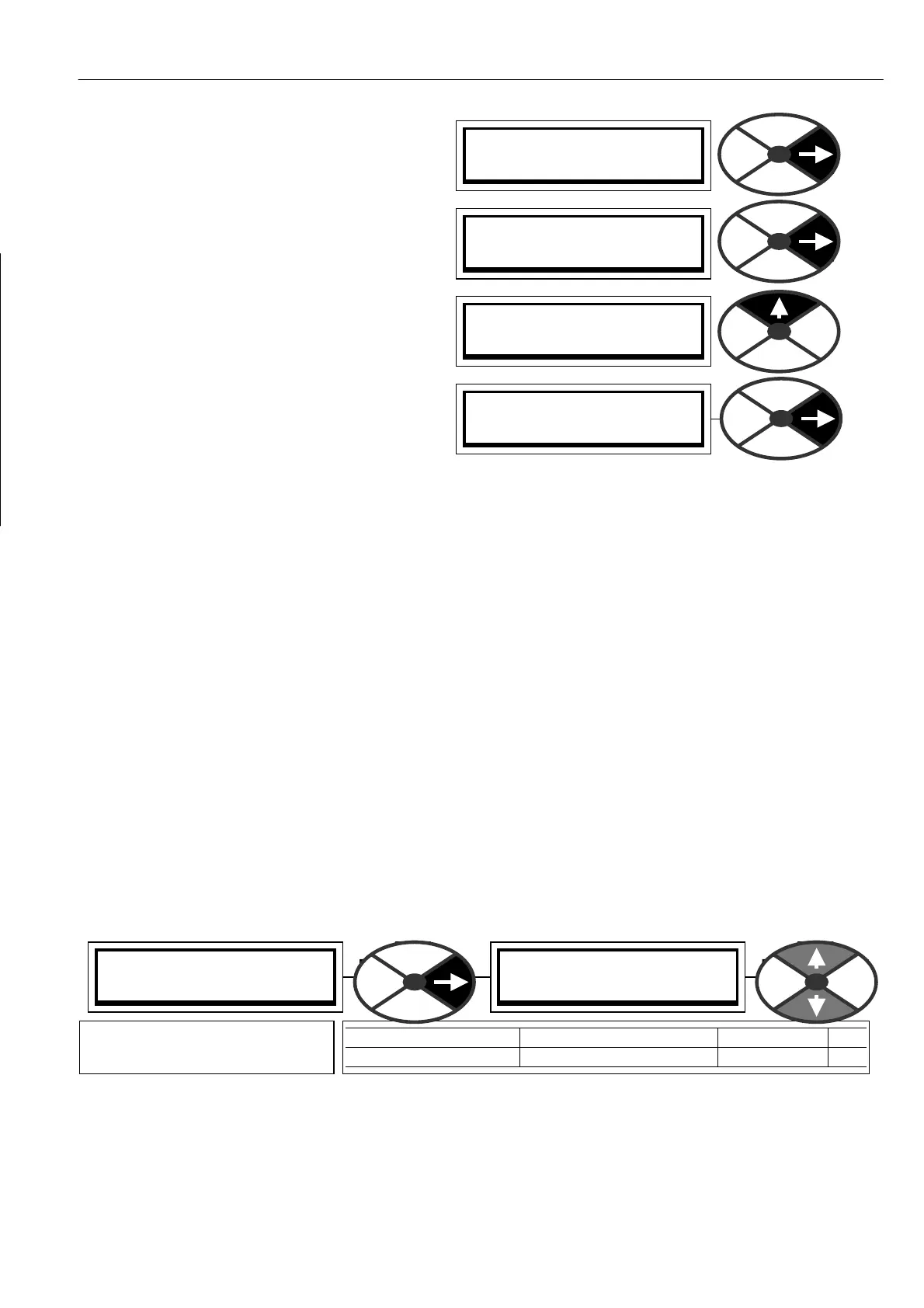

facility that will perform this function automatically. Using the keys go to CHANGE PARAMETERS /

CURRENT C ON TROL, and then to CURRENT C ONTROL / AUTO TUNE EN ABLE.

Note. The autotune function makes adjustments to the current loop error amplifier PID terms to achieve

optimum performance. When ENABLED it will wait until the main contactor is energised, and the drive run,

before starting its autotune routine. It may take from a fe w seconds up to about 1 minute typically. When it

has finished it drops out the main contactor, sets the required parameters and then automatically DISABLES

itself. You can check that it has finished by looking in the display window and waiting for the DISABLED

comment to re-appear on the bottom line. This is a stationary test. There is no need to remove the load.

PRESS RIGHT KEY FOR

ENTRY MENU LEVEL 1

ENTRY MENU LEVEL 1

CH A NGE PARA METERS 2

CH A NGE PARA METERS 2

C ALIBRA TIO N 3

CH A NGE PARA METERS 2

RUN MODE RAMPS 3

CURRENT C ON TROL 3

92)AUTO TUNE EN ABLE

92)AUTO TUNE EN ABLE

DIS ABLED

PARA METER RANGE DEF AULT PIN

AUTOTUNE EN ABLE EN ABLED OR DIS ABLED DISABLED 9 2

Enables the autotune function

to start. It turns itself off.

Loading...

Loading...