20 Introduction and Technical Data

3.1 Introduction

The PL/X DC motor controller uses closed loop control of armature current and feedback voltage to

give precise control of motor torque and speed. The unit also controls the motor excitation field. The closed

loop parameters are programmable by the user and a wealth of inputs and outputs are provided to allow very

complex motion control processes to be achieved. The series is comprised of 5 frame variants each with 2

and 4 quadrant models. Selected 2 quadrant models also offe r a unique regenerative stopping facility.

Plea se also refer to Part 3 PL/X 275-980 for extra details of frame 4 and 5 high power drives.

Programming the unit is designed to be simple. A large backlit alphanumeric display guides the user through a

friendly menu structure to select options and parameter changes. Built in application soft w are blocks are

provided to be connected up as desi red. Comprehensive fault monitoring and serial communications allo w off

site programming and remote diagnostics. All models are stock items. These units are very compact. The

savings made possible in panel space and enclosure costs may be significant.

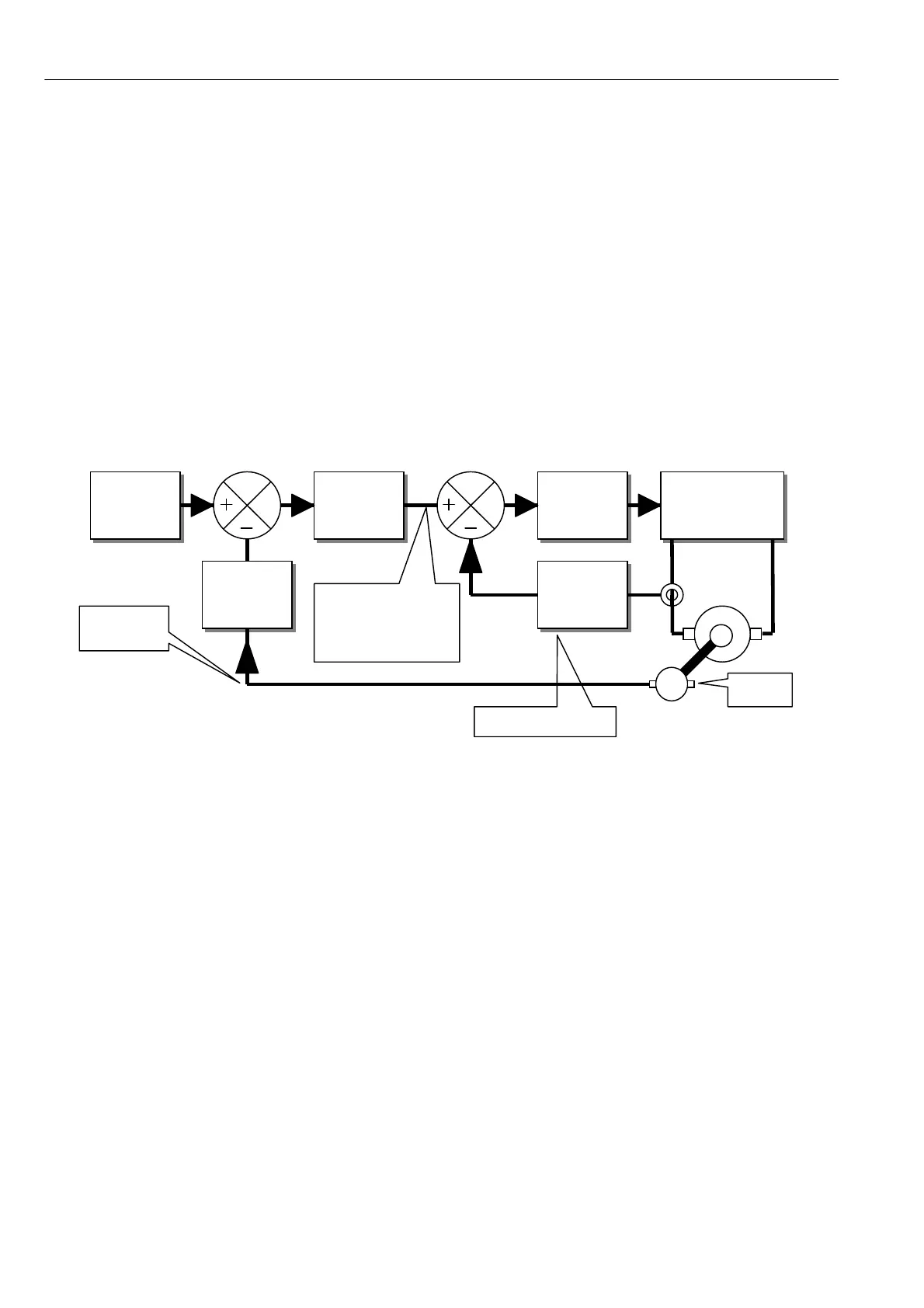

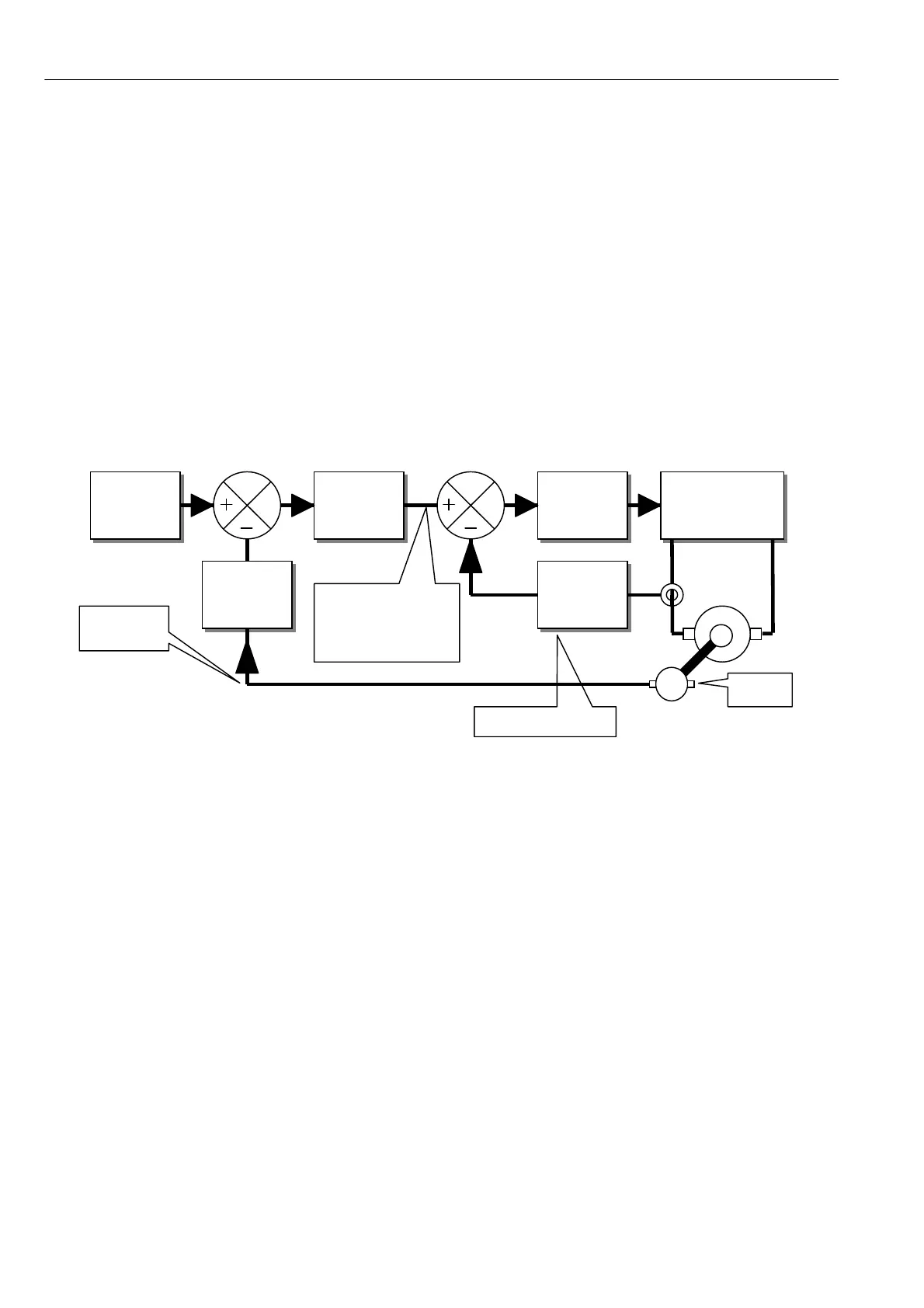

3.2 How do they work?

This shows the basic arrangement of the drive control loops. The 3-phase thyristor bridge is a phase-

controlled rectifier, which delivers po w er to the motor armature. The armature current (and hence the motor

torque) is sensed to provide feedback to the inner current loop. After being scaled this is compared to the

current demand. The current error amplifier is able to detect any difference, and then act in such a w ay that

the current feedback remains identical to the current demand during normal operation. This inner loop

monitors the armature current and delivers more current or less current as required.

The outer speed loop works in the same way as the inner current loop but uses different parameters. In the

above example, the demand is provided by the user in the form of a speed reference, and the speed feedback

is derived from a shaft-mounted tachometer. Any difference is detected and translated into a ne w current

demand level. This level provides the right amount of current (and hence torque) to reduce the speed error to

zero. This ne w demand level is presented to the inner current loop, which obeys as rapidly as possible.

The w hole process is performed on a continuous basis giving superb speed accuracy and dynamic

performance. In typical systems, there are numerous house keeping tasks and interface requirements. For

these, the PL/X series has a wealth of standard features to benefit the user.

A range of standard application blocks is included, with a user-friendly configuration facility that displays a

description of the selected connection points. The programming menu is designed for rapid travel to the

desired parameter using 4 keys and a large backlit alphanumeric display. A large number of monitoring

facilities is available to enable display of all points in the block diagram.

The unit is supplied with PL PILOT, a superb PC windo ws based configuration and monitoring tool.

(Note. Also available is the PLA, with applications blocks, I/O modules and comms facilities only)

Inner current loop

Speed

reference

from user

Current

error

amplifier

Speed

error

amplifier

Current

feedback

scaling

Speed

feedback

scaling

Firing circuit and

3-phase bridge.

A C in, DC out.

M

Tacho

The signal here

represents armature

current demand.

Outer

speed loop

Loading...

Loading...