CHA NGE PARA METERS 119

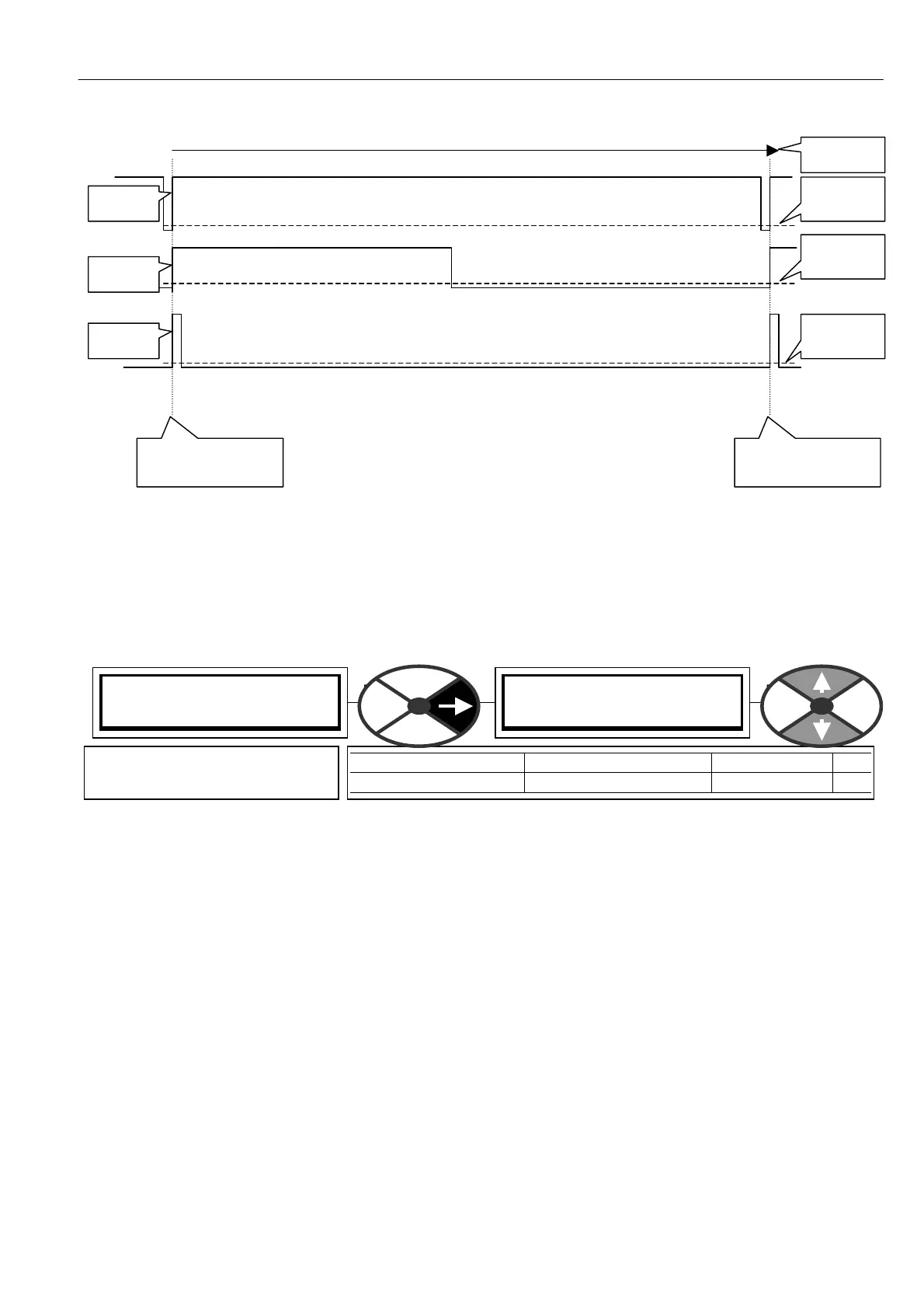

Type 1 is the preferred marker signal. This is because for most of the time the signal is well a w ay from the

logic threshold and noise is very unlikely to cause a false marker reading.

Types 2 and 3 how ever spend significant time near the logic threshold level, and therefore noise is more

likely to produce a false marker reading.

6.10.9.4 SPINDLE ORIENTATE / Marker offset PIN 241

Note. This offset is only added once at the commencement of orientation. It may be changed prior to the

next orientation sequence without affecting the existing position. The sign of the offset determines the

rotation direction w hen seeking the offset.

The count value needed for any offset angle depends on the resolution of the feedback encoder and the type

of encoder output. Quadrature encoders provide 4 counts per line. Single pulse and direction encoders

provide 2 counts per line.

E.g. Encoder has 3600 lines. Encoder type is QUA DRA TURE.

This gives 3600 X 4 counts per rev = 14400. That is 1440 0/360 = 40 counts per degree of displacement.

Hence if offset required is 56.8 degrees. Then enter counts of 56.8 X 40 = 2272.

E.g. Encoder has 2048 lines. Encoder type is SINGLE LINE PLUS DIRECTION.

This gives 2048 X 2 counts per rev = 4096. That is 4096/360 = 11.378 counts per degree of displacement.

Hence if offset required is 56.8 degrees. Then enter counts of 56.8 X 11.378 = 646.

If the encoder is mounted on the motor shaft, but the spindle that requires orientation is connected to the

motor via a gearbox such that the motor shaft and hence encoder is rotating faster than the spindle. Then

the number of counts per rev of the spindle will be increased by a factor equal to the gear box ratio.

Type 3

1 rev

Point of position

measurement

Point of position

measurement

Type 2

Type 1

Logic

Threshold

Logic

Threshold

Logic

Threshold

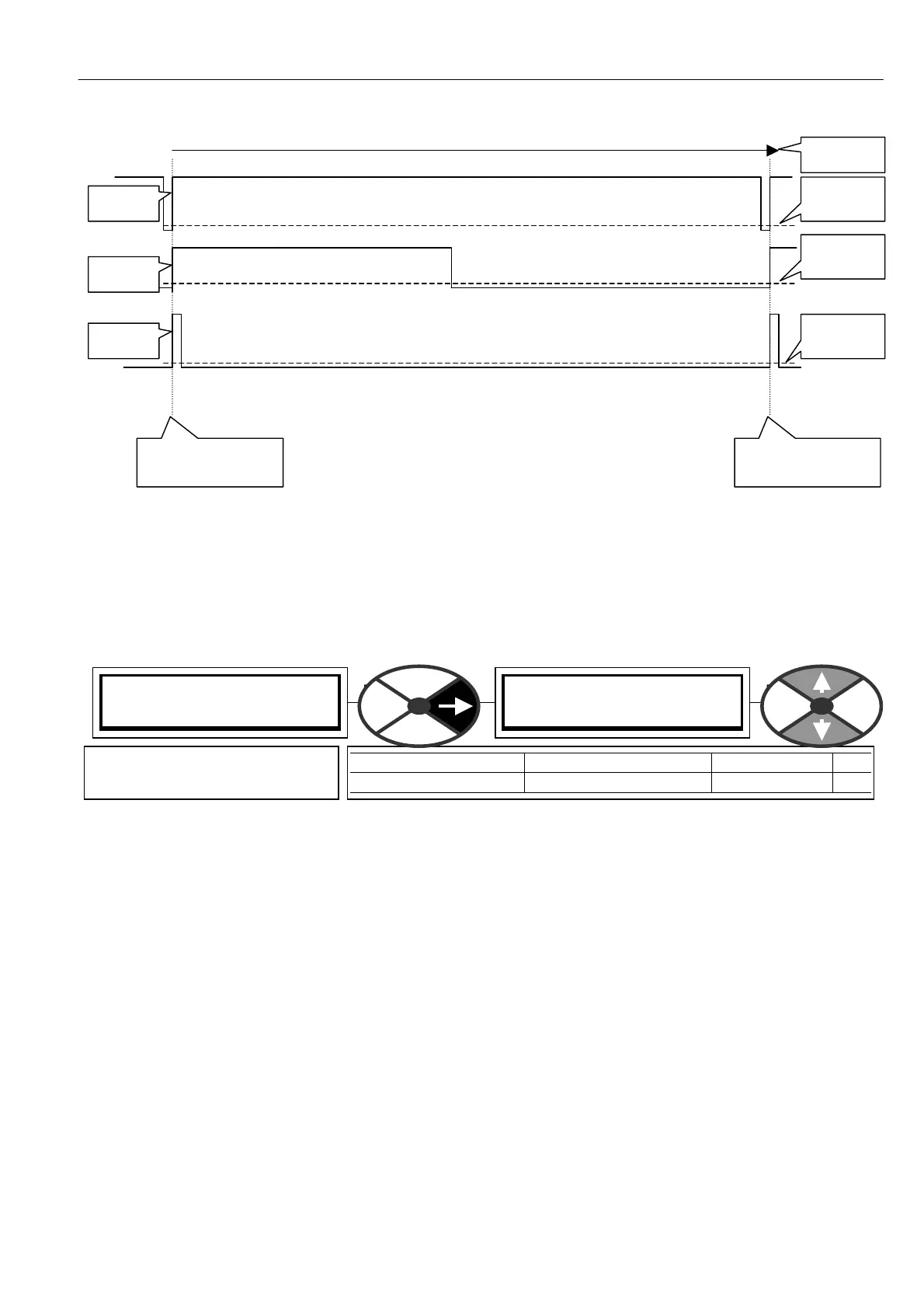

SPINDLE ORIENT ATE 4

241)M ARKER OFFSET

241)M ARKER OFFSET

0

PARA METER RANGE DEFAULT PIN

M ARKER OFFSET + /- 15,000 Counts 0 241

Used to offset an arbitrary

marker to a defined position.

Loading...

Loading...