88 CHA NGE PARA METERS

The configuration of the PL/X power terminals using L1/2/3 for stack and EL1/2/3 for field and

synchronisation is very versatile. This allo ws the main contactor to be arranged in numerous w ays.

1) EL1/2/3 permanently energised with contactor on L1/2/3 gives very fast starting and allo ws the field to

remain energised. (Required for dynamic braking or to prevent condensation in cold climates).

2) EL1/2/3 and L1/2/3 energised with main contactor allo ws total electrical isolation of the motor.

3) Main contactor on armature terminals for dynamic braking/isolation of motor.

4) L1/2/3 may be used at a very low voltage. E. g. using drive as battery charger.

See 4.3 Main contactor wiring options.

6.5.1.4 Precise stopping

For very precise performance at the ramp end points, e. g. stopping, it is useful to be able to RESET the

SPEED LO OP integrator during the ramping process. By holding it in RESET during the ramping process there

is no undesirable integral term history to intefere with the loop at the end of the ramp.

This RESET can be achieved by connecting a JUMPER from 35)RA MPING FLA G to 73)SPEED INT RESET.

See 13.2.4 JUMPER connections.

In addition, ensure that there are no small demand signals entering the speed loop by disconnecting

un wanted inputs to the SPEED REFERENCE SUMMER and setting 6.6.7 SPEED REF SUMMER /

Speed/Current Reference 3 ratio PIN 67 to zero.

Also it may be useful to have 6.7.7.1 SPEED PI A D APTION / Lo w break point PIN 74 set to 0.2 % and

6.7.7.3 SPEED PI AD APTION / Low breakpoint proportional gain PIN 76 set lo w (e. g. 5.00) to minimise

the effects of tacho noise at the stopping point.

See also 6.10.8.1 Low speed performance.

6.5.2 ST OP M ODE RA MP / Stop ramp time PIN 56

A standard 4 quadrant drive can motor and brake in both forward and reverse. It can also stop very quickly

by returning mechanical rotational energy to the supply. It does this by effectively using the motor as a

generator and the supply as a load to dump the energy in.

A standard 2 quadrant drive can only motor in the forward direction, and cannot regenerate w hen stopping.

Selected models in the PL 2 quadrant range have a special feature which allows them to regenerate when

stopping. This feature not only saves considerable amounts of energy but also eliminates the requirement for

dynamic braking resistor systems.

See 3.3.1 Regenerative stopping with PL models.

6.5.3 ST OP M ODE RA MP / Stop time limit PIN 57

This is initiated by the start input going lo w.

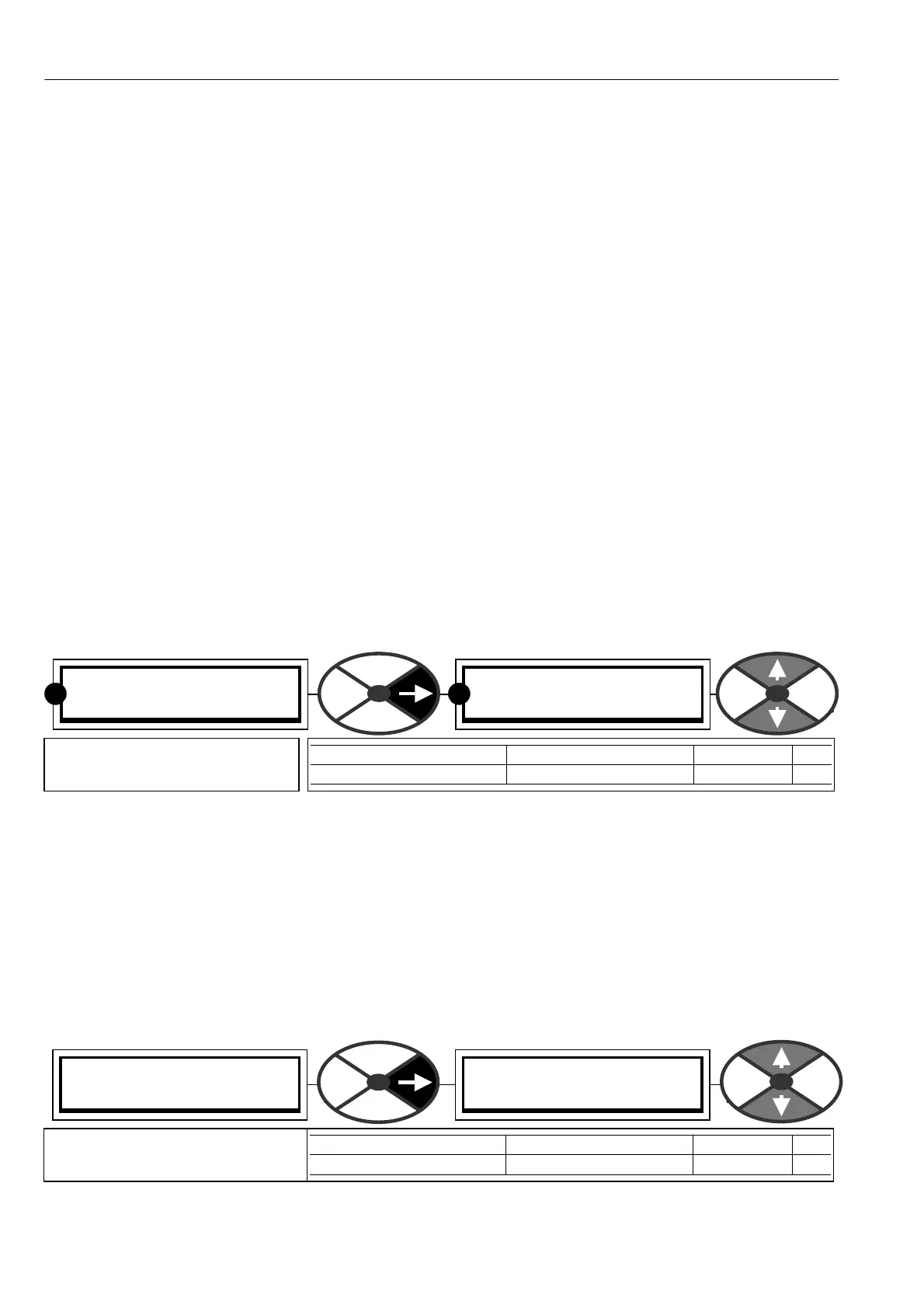

STOP MODE RAMP 3

56)ST OP RA MP TIME

56)ST OP RA MP TIME

10.0 SECS

PARA METER RANGE DEFAULT PIN

STOP RAMP TIME 0.1 to 600.0 secs 10.0 secs 56

Sets the 100 - 0% do wn ramp

time in normal stop mode

R R

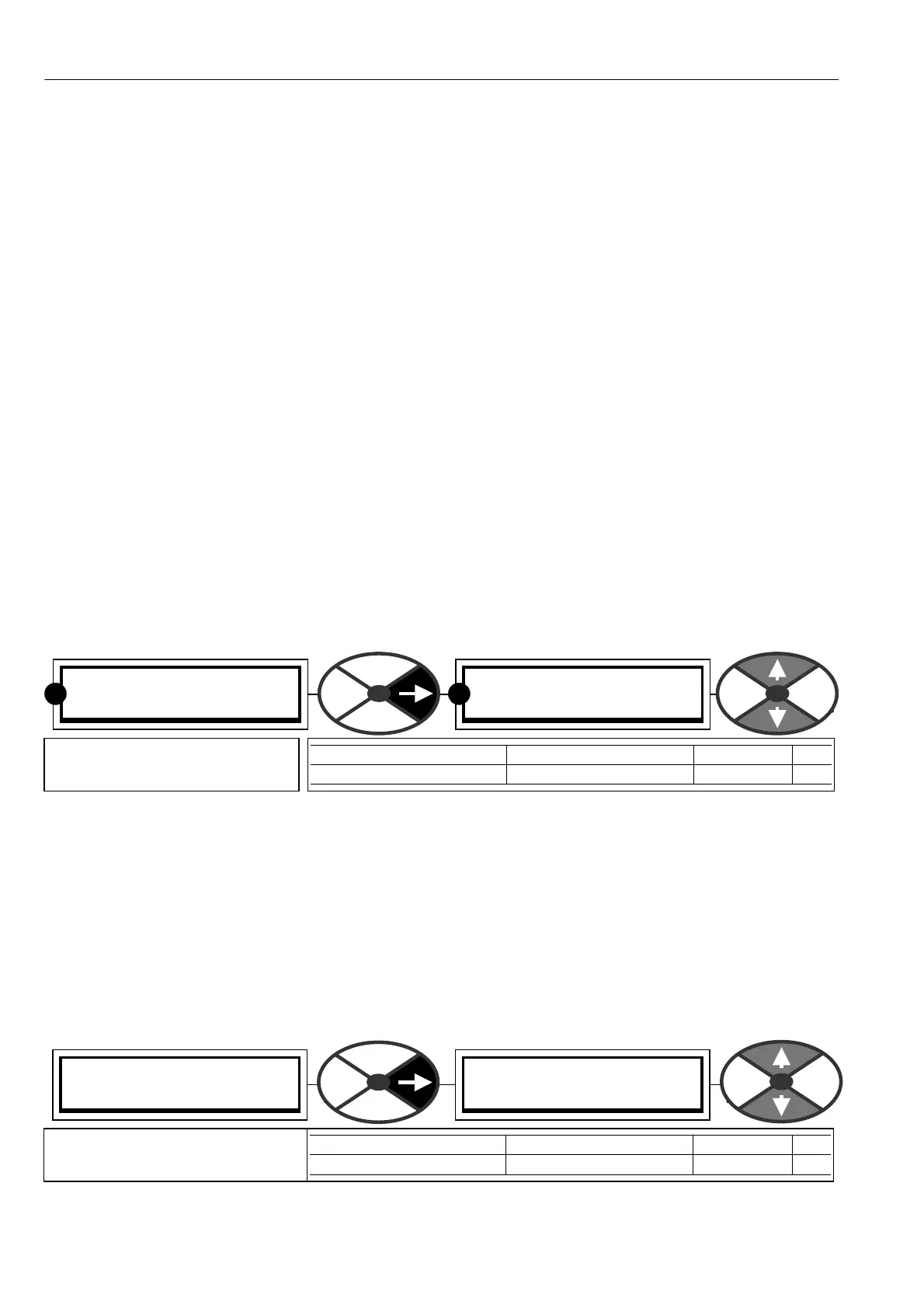

STOP MODE RAMP 3

57)ST OP TIME LIMIT

57)ST OP TIME LIMIT

60.0 SECS

PARA METER RANGE DEFAULT PIN

STOP TIME LIMIT 0.0 to 600.0 secs 60.0 secs 57

Sets the max time limit before

contactor drop out in stop mode

Loading...

Loading...