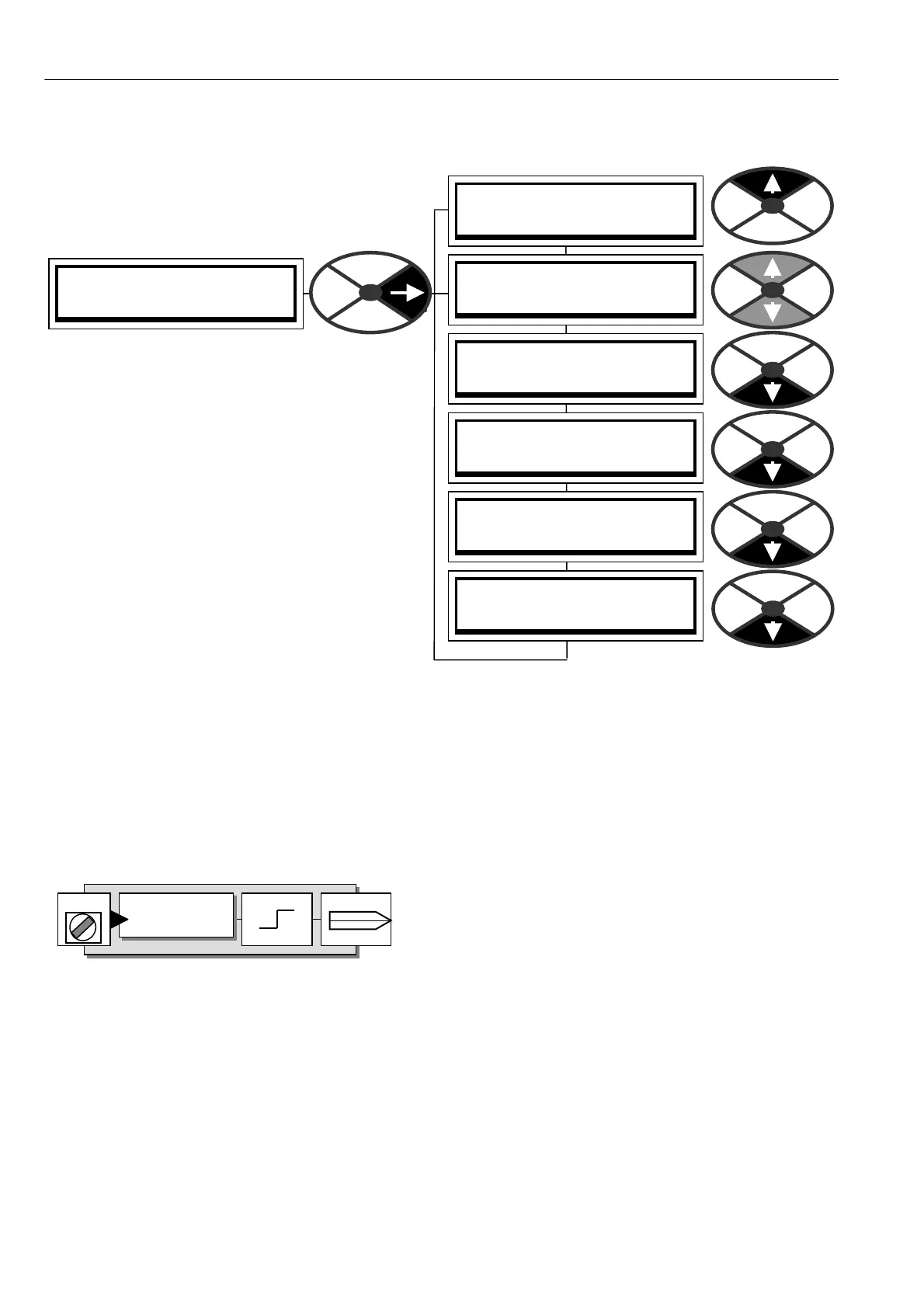

116 CHA NGE PARA METERS

ZERO INTERLO CKS 3

SPINDLE ORIENT ATE 4

SPINDLE ORIENT ATE 4

244)IN POSITION FLA G

SPINDLE ORIENT ATE 4

122)ZERO SPEED LO CK

SPINDLE ORIENT ATE 4

240)M ARKER EN ABLE

SPINDLE ORIENT ATE 4

241)M ARKER OFFSET

SPINDLE ORIENT ATE 4

242)POSITION REF

SPINDLE ORIENT ATE 4

243)M ARKER FREQ MO N

6.10.9 ZERO INTERLOCKS / SPINDLE ORIENTATE

PINS used 122 and 240 to 244

Note. It is only possible to use this function with

PLX models, and PL models with the regenerative

stopping facility. See 3.3.1.

This sub menu is used to provide spindle

orientation. It requires the mechanic al syste m to be

fitted with an incremental encoder with bi-

directional output to provide position feedback.

If the encoder has been selected for a speed

feedback option in the C ALIBRA TION menu then

that function is not disturbed by this block being

operational.

The spindle orientation will function irrespective of

the speed feedback type.

The block utilises the encoder marker to provide

the controller with the absolute position angle of

the encoder. The marker is input via terminal T 15.

PL models with the regenerative stopping facility can only orientate during the contactor drop out delay.

To maintain position lock during a contactor drop out delay ensure 6.5.4 STOP MODE RA MP / Live delay

mode PIN 58 is set to ENABLED. See also 6.5.6 ST OP MODE RA MP / Drop-out delay PIN 60.

The encoder pulses are input on terminals T16 and T17 (Note. Quadrature type encoders are recommended

because they will usually provide more accurate counting during reversals than Pulse and direction types).

Terminals T15, T16, T17 are also used as standard logic inputs. (DIP/2/3/4). This function continues to

operate. However logic levels that are changing at a frequency of greater than 20 Hz will not necessarily be

recognised by the standard logic input function. The standard logic input function can be useful to check

logic output levels of a slowly rotated encoder during commissioning.

The encoder input type and scaling is programmed by using

the C ALIBRA TION / EN CODER SC ALING menu to select the

encoder type, sign, encoder lines and rpm.

The SPINDLE ORIENT A TE block counts the pulses from the encoder in a bi-directional counter. It counts

forward or backward depending on rotation direction. This count represents the amount of angular rotation of

the encoder and hence the motor shaft. The position count is compared with the required spindle orientation

position reference to develop an error signal which is employed in a negative feedback loop in the drive. Thus

the motor will rotate in such a direction as to reduce the error to zero, and hence bring the encoder marker to

the spindle position reference.

The marker uniquely defines the absolute position of the rotating encoder to the machine. If 241)M ARKER

OFFSET and 242)POSITIO N REF are both zero, then the encoder shaft will be positioned at the marker.

How ever it is more than likely that the marker will be in an arbitrary position. To overcome this problem,

241)M ARKER OFFSET is provided to perform a one off positioning of the shaft to a know n position, every

time the spindle orientate is actioned. E. g. to top dead centre.

242)POSITION REF is then always referred to this kno wn position.

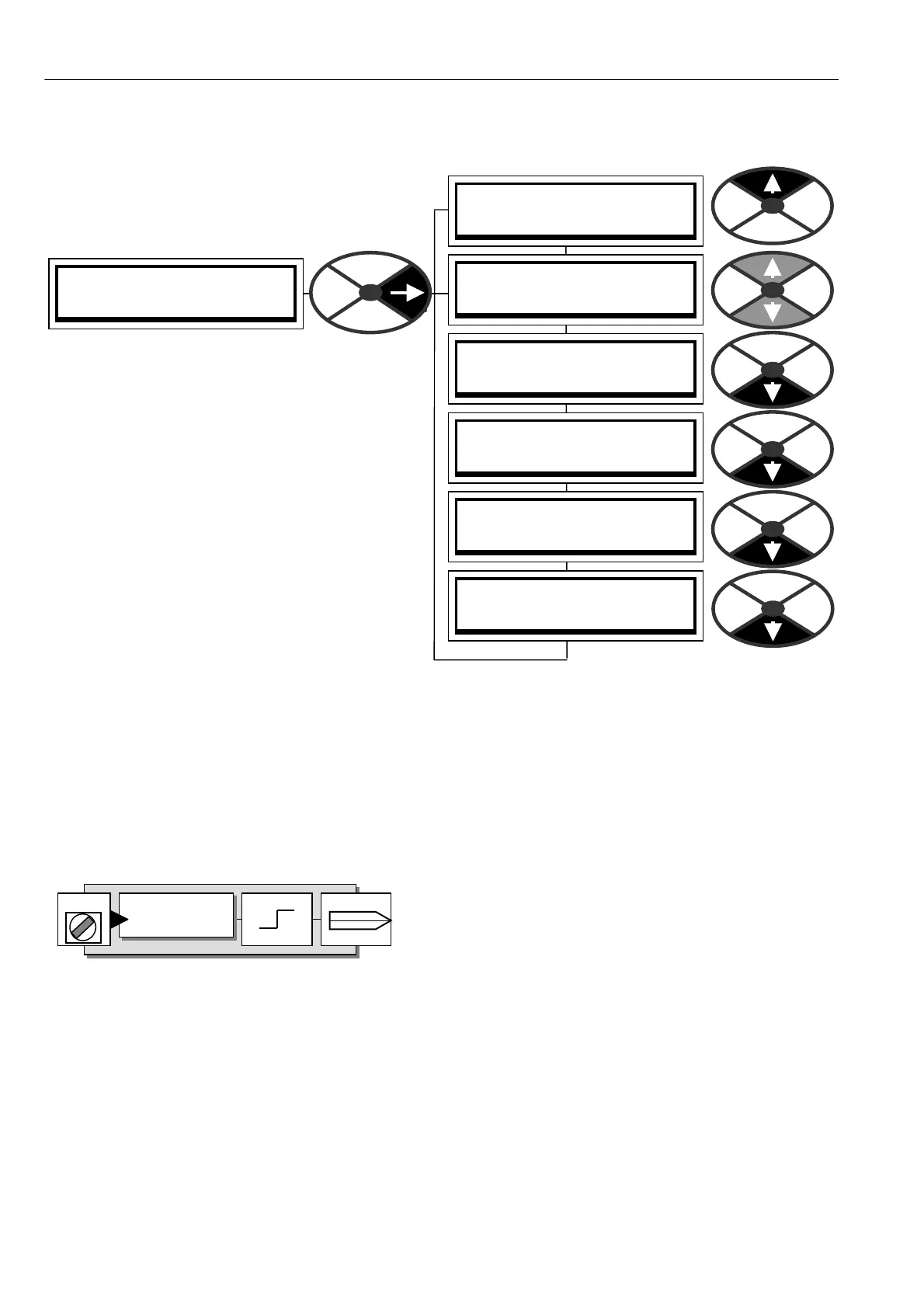

PIN X X X

PIN X X X

DIPX

Input terminal

T15/1 6/17

G O T O

High OP val

Low OP val

Loading...

Loading...