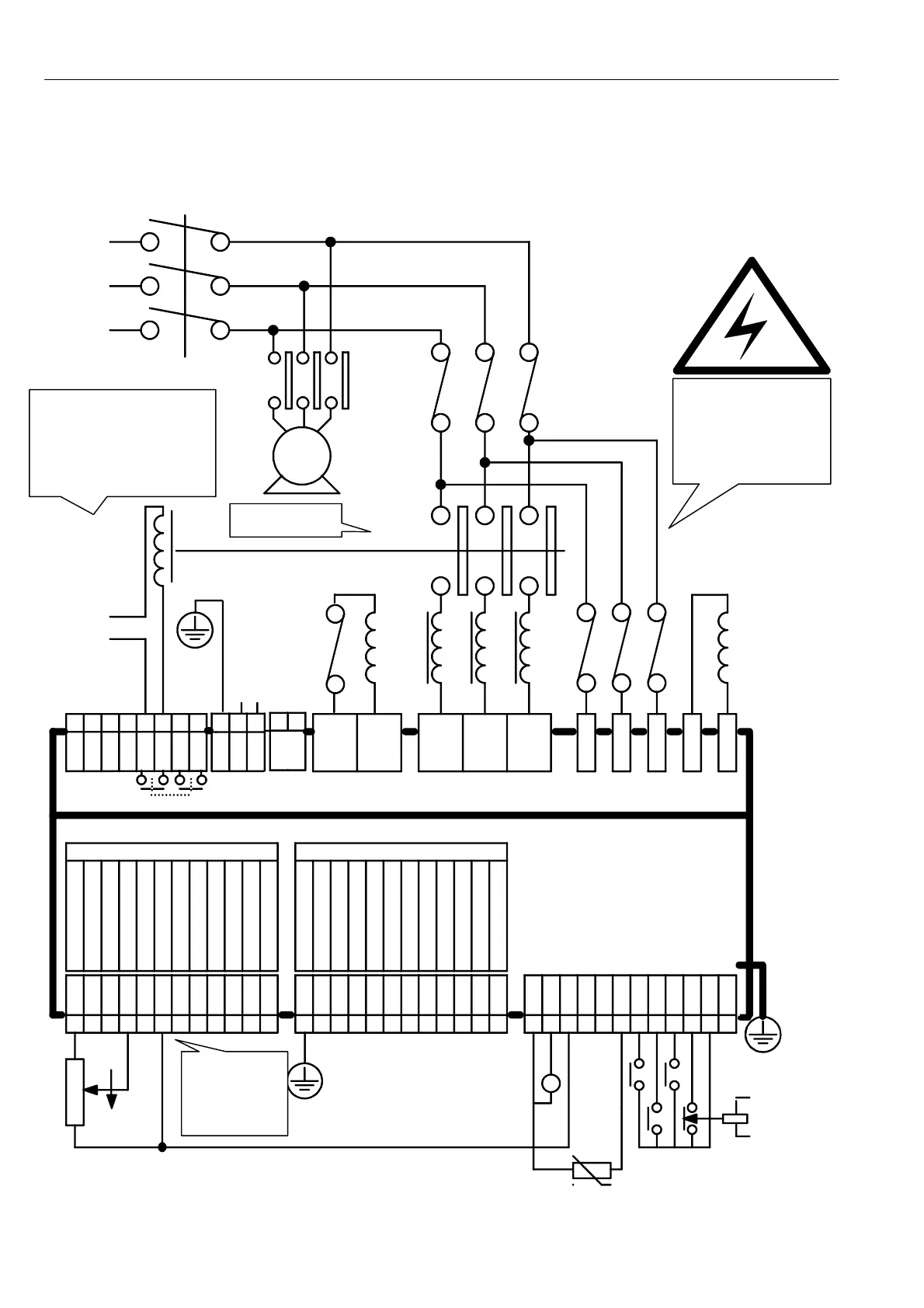

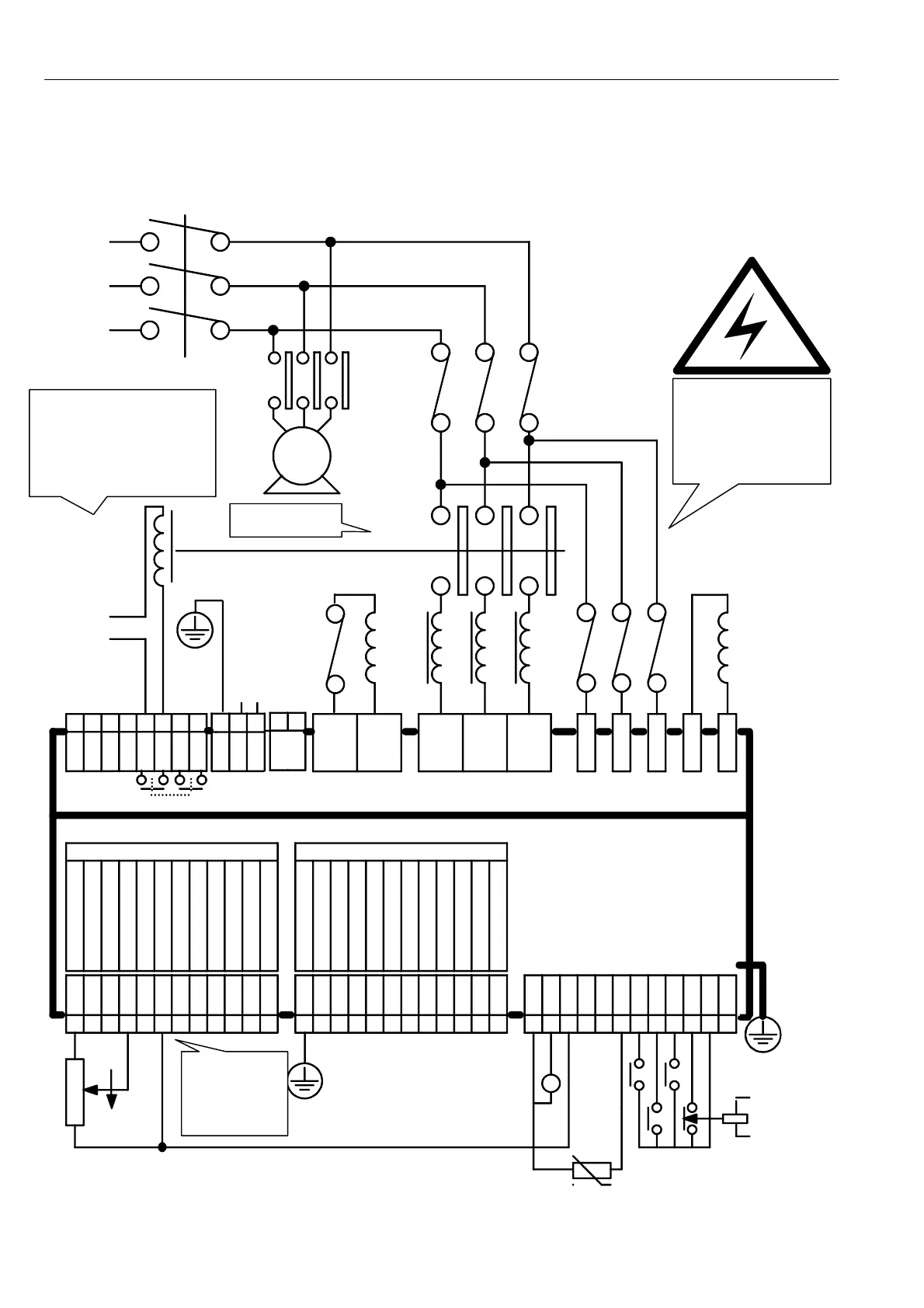

34 Basic application

4.1 Basic speed or torque control

This section sho ws the essential requi rements for a very basic speed or torque control application.

Note that the arrangement of the contactor shown here allo ws continuous phase sensing on EL1/2/3.

VERY IMPORTANT see 4.2 Main Contactor operation, 4.3 Main contactor wiring options, 14 Installation.

Note. B1, B2 Fan supply is 110V AC 50VA for PL/X185-265 and 240V AC 100VA for PL/X 275-980.

1

0V

13

0 V

2 3 4 5 6 7 8 9

10 11 12

UIP2

UIP3

UIP4

UIP5

UIP6

UIP7

UIP8

A OP1

A OP2

A OP3

0V

DIP1

DIP2

DIP3

DIP4

14 15 16 17 18 19 20 21 22 23 24

DIO1

DIO2

DIO3

DIO4

DOP1

DOP2

DOP3

25 26 27 28 29 30 31 32 33 34 35 36

TA CH

+ 10

-10

IARM

THM

RUN

JOG

ST ART

CSTOP

+ 24V

0V

41 42 43 44 45 46

51 52 53

RA +

NC

RA-

CON1

EARTH

N

L

NC

CON2

A + A- L1 L2 L3

EL1

EL2

EL3

F-

F +

TERMIN ALS 1 -1 2 FUNC TIO N TERMIN ALS 13 -2 4 FUN CTIO N

110 V

A C IP

FAN

B1 B2

Terminals show n on the top edge are located on the lower level power board. (B1/B2 on top edge of 1 85/225/265 models)

Symbolic connection block.

Terminals 1 - 36 are located on the

bottom edge of the upper control

board arranged as 3 blocks of 12.

Terminals 2 -12, 14 - 24, and 31

are programmable.

Their default function is shown here.

Speed ref/Current ref

Ramped Speed Setpoint

Lower Current Clamp

Main/Upper Current Clamp

Motorised Pot Preset

Motorised Pot Increase

Motorised Pot decrease

Speed Feedback

0V Terminal

Total Speed Reference

Total Current Demand

Speed Reference

0V Terminal

Zero reference interlock

Jog Speed Select

Ramp Hold

Current Clamp Select

Spare input

Spare input

Feedback encoder

Feedback encoder

Zero Speed

Ramping flag

Drive Healthy

contactor

coil supply

110V A C

3 phase

motor

blower

circuit

breaker

main

semi-conductor

fuses

main

contactor

main

contactor

coil

Isolator

armature

field

line

reactor

auxiliary

semi-conductor

fuses

L3

L2

L1

10K

speed pot

cw

acw

emergency

stop relay

startjog

run

T

+

thermistor

UIP9

AC Control

Supply Inputs

(110 -240V)

Protective

clean earth.

Control supply

dirty earth

47 48

LA T1

LA T 2

Substantial

chassis

earth

Use DC semiconductor

fuse for

regen

applications

W ARNING. Do not

allow coil supply to be

externally interrupted.

Retro- fit relay logic is

often the main culprit.

W ARNING

The phase order

of EL1/2/3 must

be the same as

L1/2/3

For Torque control

enter Torque ref

into T6. (0 - 1 0 V).

For speed control

link T 6 to + 1 0V

on T 27.

A C 1 rated

Loading...

Loading...