42 Basic application

4.5 CONTROL ENGINEERING COMMISSIONING PROCEDURES

Before applying power to the L1/2/3 terminals for the first time, it is recommended that a high w attage

resistor of between 4 and 40 Ohms (E.g. a 1 Kw fire bar) is inserted in series with the armature.

This will limit any potentially destructive current and prevent possible thyristor damage.

(A typical example of the cause of fault current is the incorrect phasing of the EL/1/2/3 terminals with

respect to L1/2/3. Without the correct semi-conductor fuses this may result in thyristor damage on the

application of the start command).

(Note. The fire bar will be removed prior to performing the A UTOTUNE procedure as described later).

1) For systems using field weakening, start with the unit calibrated for armature voltage feedback first in

order to verify normal operation up to base speed. Then introduce field w eakening only after careful

calibration, and s witching to either tacho or encoder feedback.

2) For systems employing torque control it is recommended to set up in basic speed mode first in order to

establish correct speed loop functioning and calibration.

4.5.1 Quick start calibration

Assuming that the drive unit is correctly installed and the motor and load are safe and ready to be rotated,

then the next task is to calibrate the drive to suit the supply and the motor.

The PL/X series has a method of calibration which avoids the need to solder resistors and set s witches. All

the fundamental drive scaling parameters can be programmed via the on board display and menu keys.

Once the initial calibration menu is completed the chosen limits may be saved and will remain unaltered

unless you wish to re-calibrate. There is also the choice of using a password to prevent unauthorised re-

calibration.

The unit automatically kno ws the model armature current ratings and will prevent setting of armature current

in excess of the model rating.

See 13.13.4 DRIVE PERSONALITY / Armature current burden resistance PIN 680.

The parameters that will be selected for quick start calibration are as follo ws

See 6.1 CHA NGE PARA METERS / C ALIBRA TION for a full explanation of these parameters

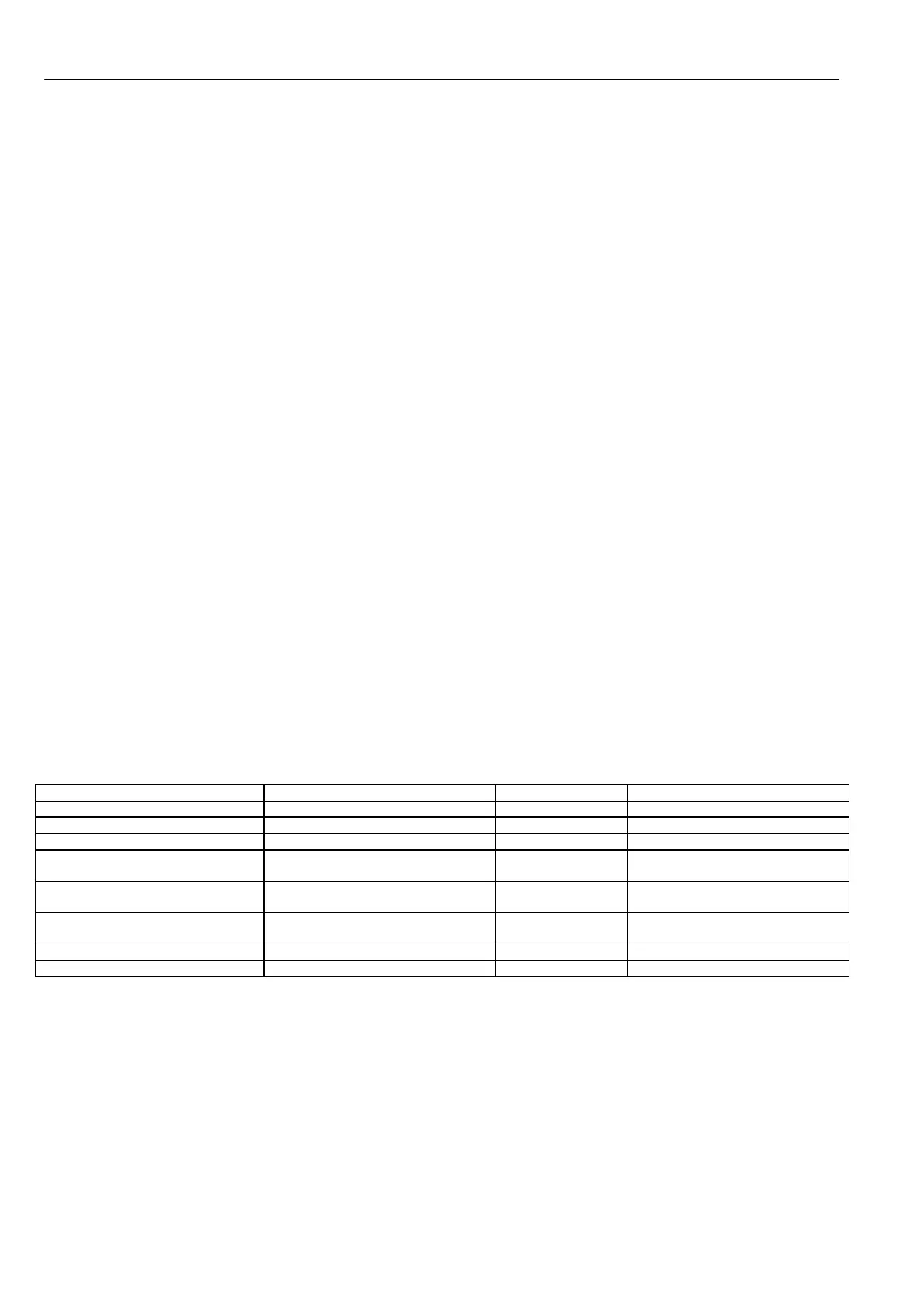

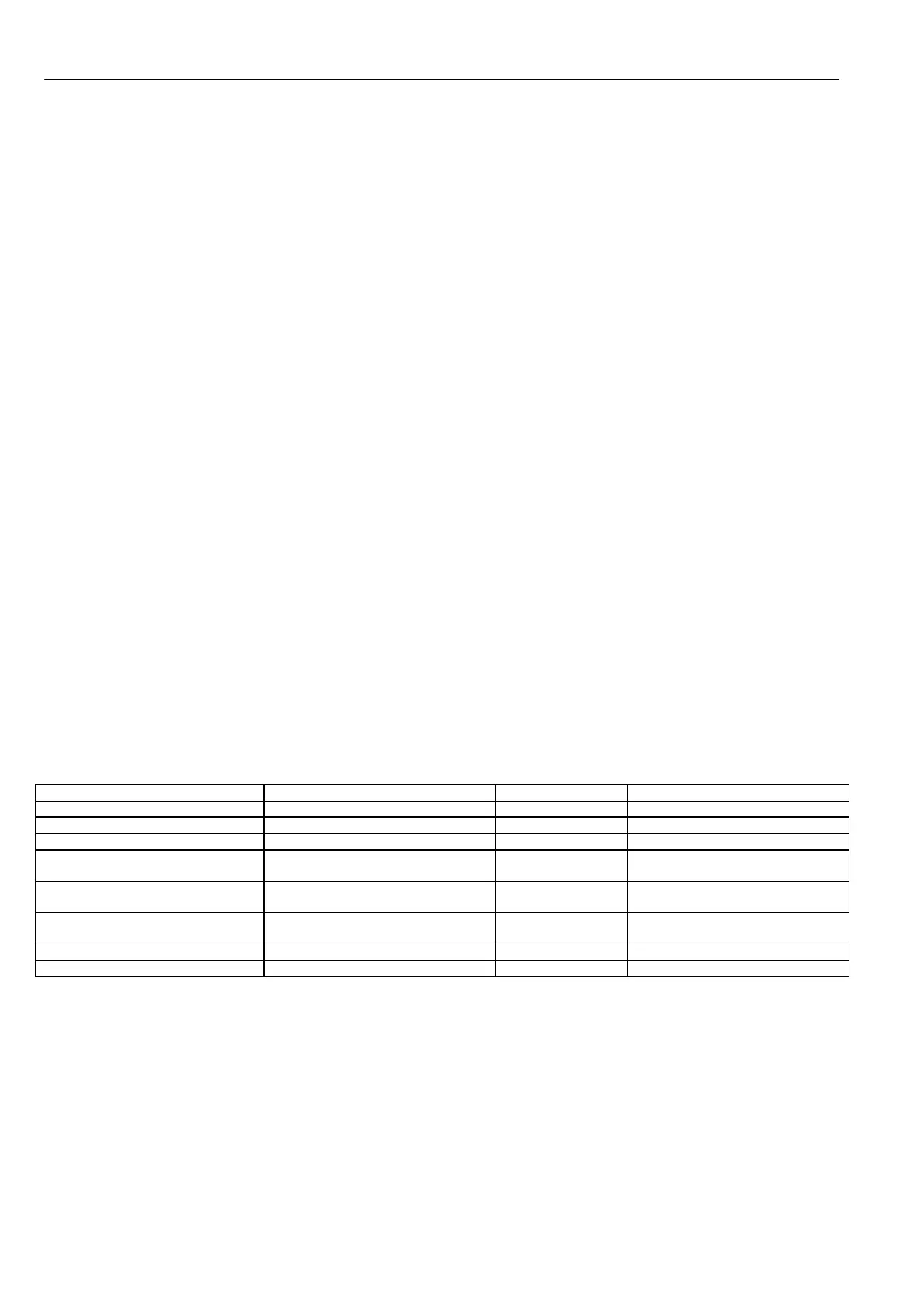

Parameter Range Factory default Entered Units

2)RA TED ARM A TURE A MPS 33 –100 % of unit rating 33% Amps

3)CURRENT LIMIT % 0 –150% of unit rating 150 % %

4)RA TED FIELD A MPS 0.1A – 10 0 % of unit rating 25% Amps

5)BASE RA TED RPM 0 - 6000 150 0 Revs per minute of motor at

maximum armature volts

6)DESIRED M A X RPM 0 - 6000 1500 Max revs per minute of motor at

your desired max speed

9)SPEED FEEDB A CK TYPE Armature voltage (select this one)

plus 4 other choices

Armature

voltage

Armature voltage

18)RATED ARM VOLTS 0 – 1000.0 V OLTS D C 460 Volts

19)EL1/2/3 RA TED A C 0 to 1000.0 415 V Volts A C

By selecting Armature Voltage a quick start is more easily achieved.

1) The speed feedback is alw ays present, and in the correct polarity.

2) The motor and/or load can be seen to be rotating correctly and at approximately the correct speed.

3) If a tachogenerator or encoder is fitted then it can be checked for the correct polarity and output levels

prior to including it in the feedback loop.

4) Other parameters such as ramp rates and stopping modes can be checked and or set before

proceeding to final accurate calibration.

5) The system may need pre-test prior to shipping and no tachogenerator is available. For this quick start

procedure it is only necessary to set the above parameters.

Loading...

Loading...