CHA NGE PARA METERS 67

6.1.10.2 ENC ODER SC ALING / Encoder lines PIN 11

The number of lines on the encoder dataplate should be entered. Alternatively enter the number of cycles of

high/low for one pulse train during one revolution. E. G. for a toothed gear wheel with 60 teeth and a

magnetic pick up, enter the number 60. Note that there is an upper frequency limit of 10 0 kHz.

6.1.10.3 ENCODER SC ALING / Motor / encoder speed ratio PIN 12

Note. The encoder is sometimes not fixed to the motor shaft, and may rotate at an RPM that is a non unity

ratio of the motor RPM. Some systems have the encoder geared up to obtain a higher feedback frequency.

MO T/ENC SPD RA TIO = Motor RPM / Encoder RPM (true for all speeds)

When using encoders it is advisable to initially run the system in A V F mode to verify the integrity of the

encoder feedback signals using an oscilloscope. Then after setting the QU A DRA TURE EN ABLE and EN CODER

LINES parameters, run the system in A VF feedback mode, and monitor 132)ENC ODER RPM in the

DIA GNOSTICS menu. This will verify the encoder operates as expected prior to using it as a feedback source.

Note. An encoder may be input and used for other tasks instead of feedback.

On hidden PIN 709)M OT OR RPM %, is the encoder feedback %, scaled to 100% = 6)DESIRED MA X RPM.

It is also scaled by 12)MOT/EN C SPD RA TIO w hich acts as a pure multiplying factor.

Both 132)ENCODER RPM and PIN 709)MOTOR RPM %, are purely encoder signals, that work independently

of the type of feedback selected. They both r ead zero wi th no pulses on the encoder inputs.

6.1.10.4 ENCODER SC ALING / Encoder sign PIN 13

Use this to invert the encoder feedback sign if needed. Note, in combined feedback modes type 3 and 4,

with single line encoders, the feedback sign is automatically taken from the A VF or tacho if SPINDLE

ORIENT A TE is not employed. (T16 digital input is made free for other uses).

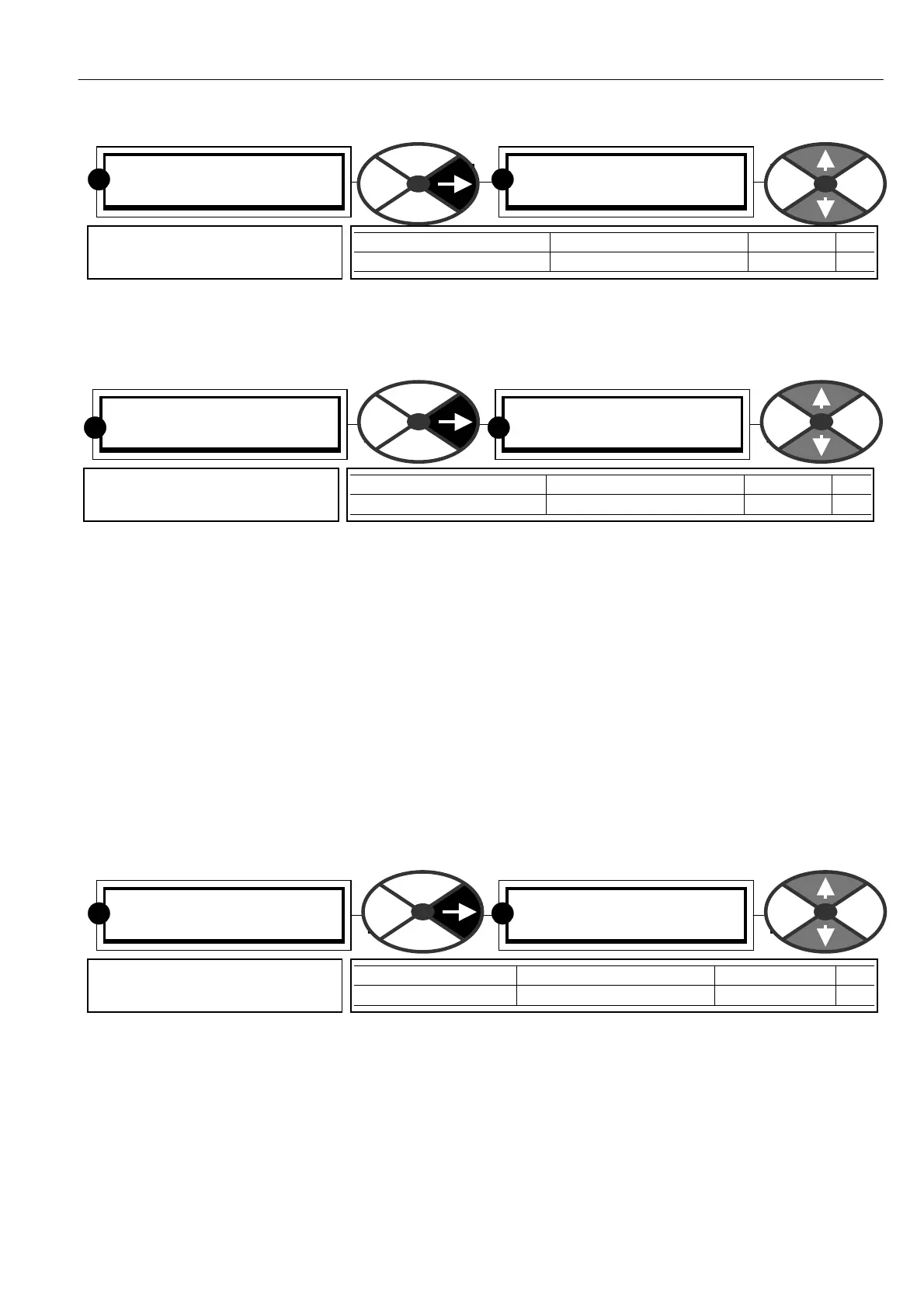

ENCODER SC ALING 4

11) ENCO DER LINES

11)ENC ODER LINES

1000

PARA METER RANGE DEF A ULT PIN

ENCODER LINES 1 to 6000 1000 11

Inputs the encoder resolution in

pulses per rev .

RR

ENCODER SC ALING 4

12)M OT/ENC SPD RA TIO

12)M OT/ENC SPD RA TIO

1.0000

PARA METER RANGE DEF A ULT PIN

MO T/ENC SPD RA TIO 0.0000 to 3.0 00 0 1.00 00 12

Sets the motor revs as a ratio

of the encoder revs.

R

R

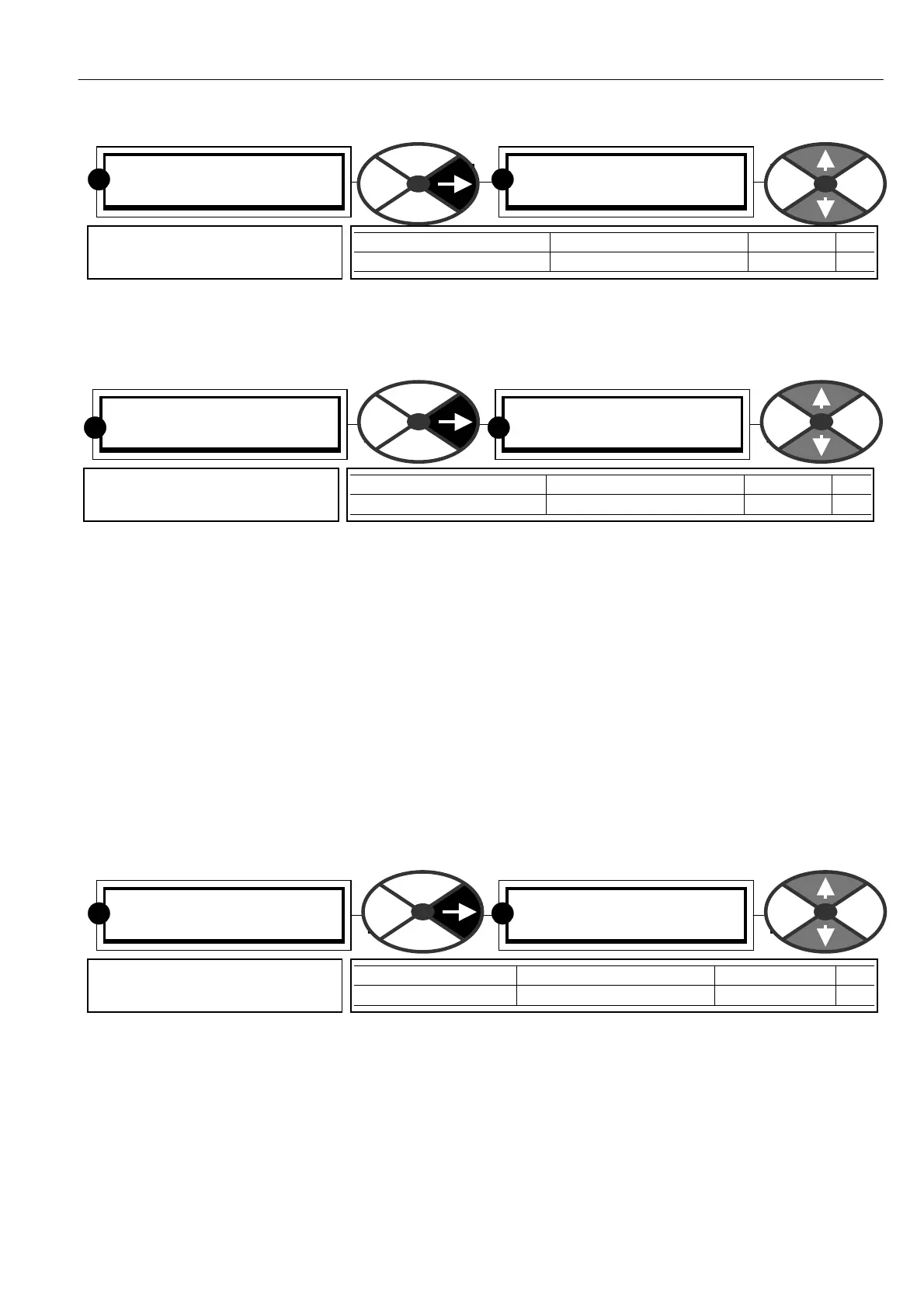

ENCODER SC ALING 4

13)ENC ODER SIGN

13)ENC ODER SIGN

NON-INVERT

PARA METER RANGE DEF A ULT PIN

EN CODER SIGN NON-IN VERT or IN VERT NON-IN VERT 13

Modifies the encoder rotation

sign.

RR

Loading...

Loading...