Chapter 12 Description of Parameter Settings

MH300

Settings

Functions Descriptions

52

Output control for

communication cards

Control the output through communication cards

(CMM-PD02, CMM-EIP02, CMM-EC02, CMM-DN02)

Setting for related

parameters

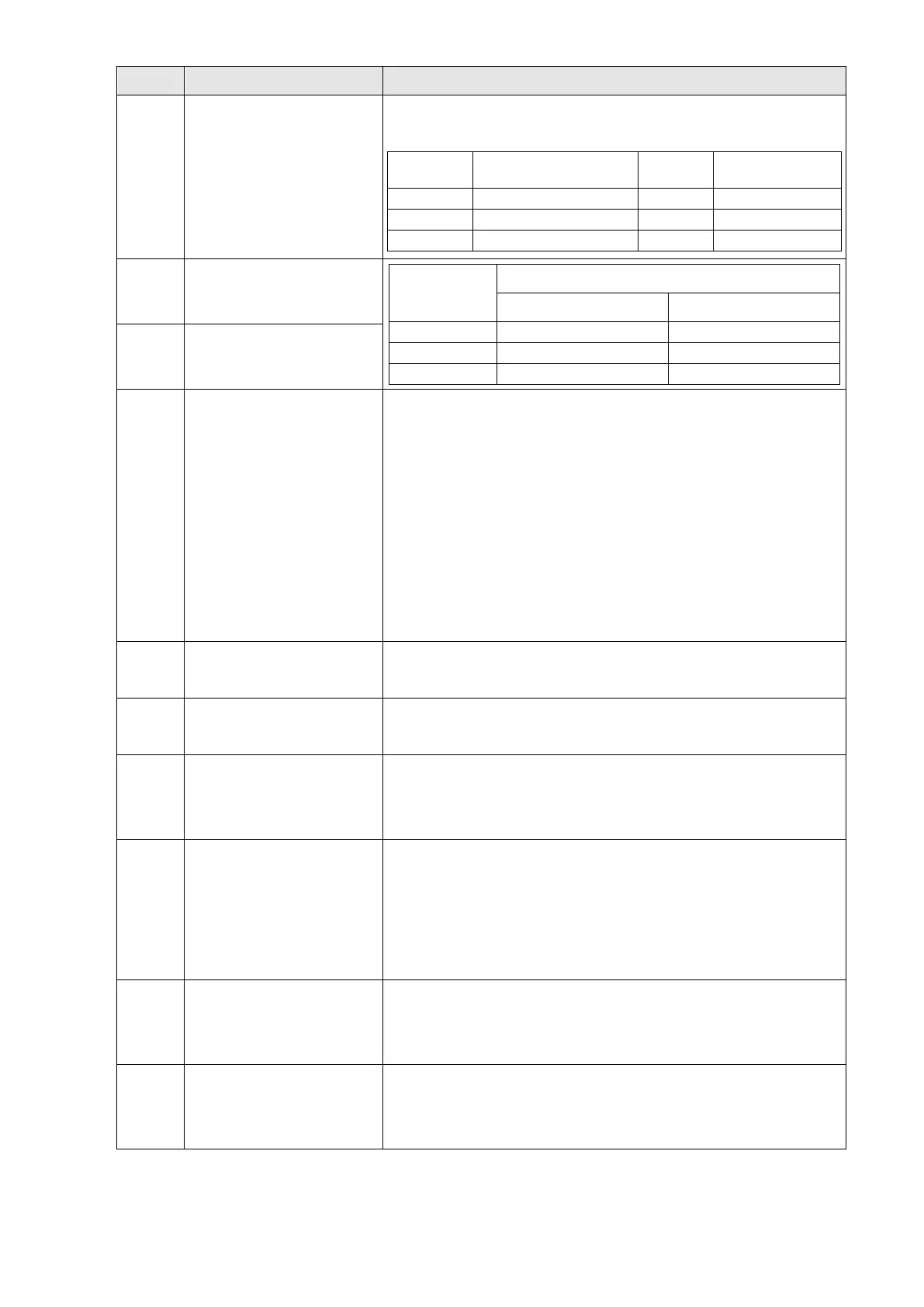

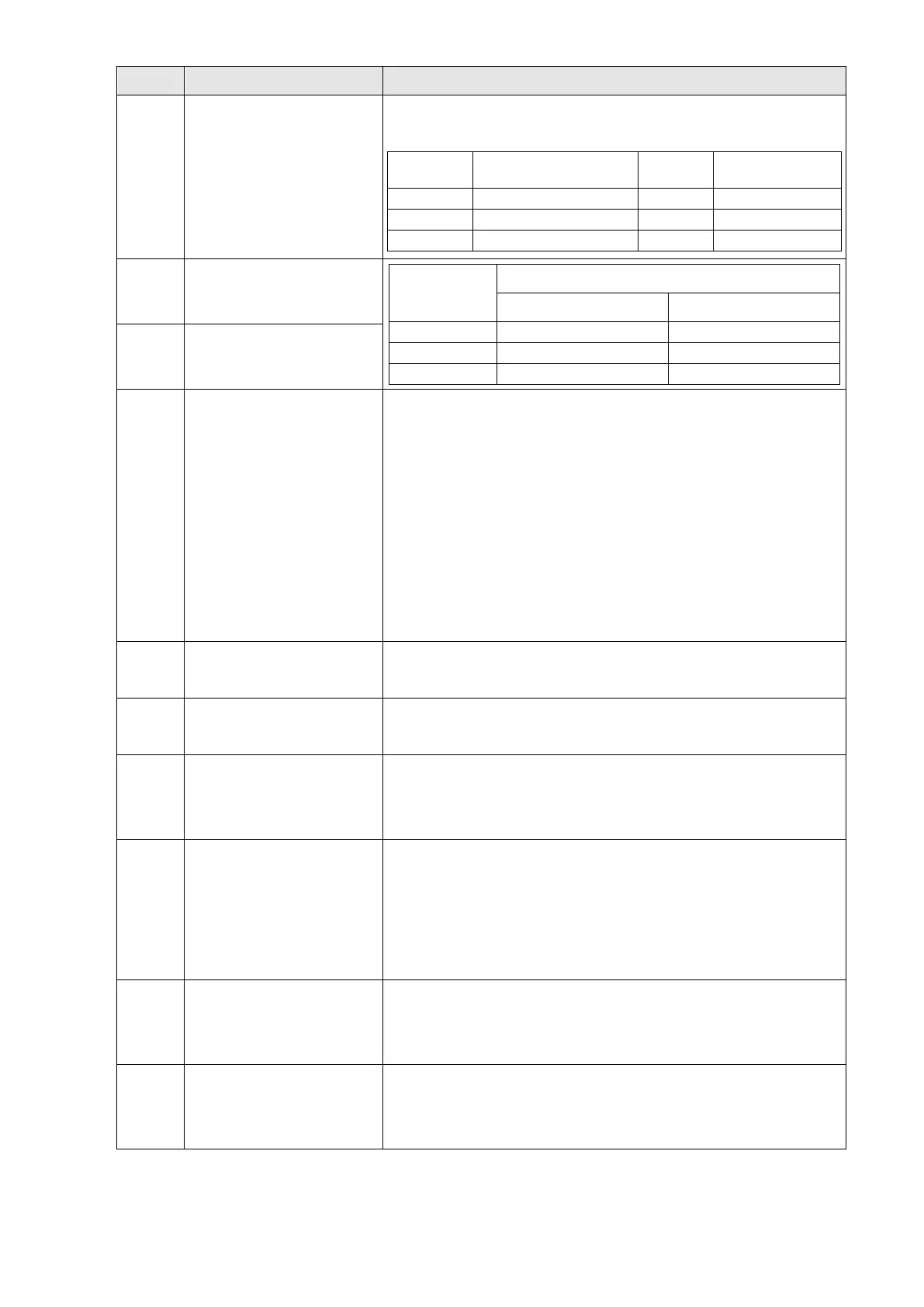

66 SO output logic A

Status of

the drive

Status of the safety output

Status A (MO = 66) Status B (MO = 68)

68 SO output logic B

67

Outputs when analog

input level reached

The multi-function output terminals operate when the

input level is between the high level and the low level.

Pr.03-

44: Select one of the analog input channels (AVI, ACI)

to be compared.

Pr.03-45: The high level for the analog input, default is 50%.

Pr.03-46: The low level for the analog input, default is 10%.

If analog input > Pr.03-45, the multi-function output terminal

operates. If analog input < 03-46, the multi-function output

terminal stops output.

69

Maximum reel diameter

reached

In tension control mode, when reel diameter reaches

Pr.12-22, the contact closes.

70

Empty reel diameter

reached

In tension control mode, when reel diameter reaches

Pr.12-23, the contact closes.

71 Broken belt detection

In tension control mode, a broken belt occurs when line

speed is higher than Pr.12-40, the error of reel diameter

exceeds Pr.12-40, and the detection time exceeds Pr.12-41.

72

Tension PID feedback

error

In tension control mode, when the difference between the

PID target value and the PID feedback exceeds Pr.12-42,

and the allowed error detection time for tension PID

feedback exceeds Pr.12-43, refer to Pr.12-43 for the error

treatment of the tension PID feedback.

73 Over-torque 3

Active when over-torque is detected. Pr.14-75 sets the over-

torque detection level. Pr.14-76 sets the over-torque

detection time (refer to Pr.14-74–14-76).

74 Over-torque 4

Active when over-torque is detected. Pr.14-78 sets the over-

torque detection level. Pr.14-79 sets the over-torque

detection time (refer to Pr.14-77–14-79).

Loading...

Loading...