AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

OPERATING PRINCIPLES Electrical parts layout 16

Confidential

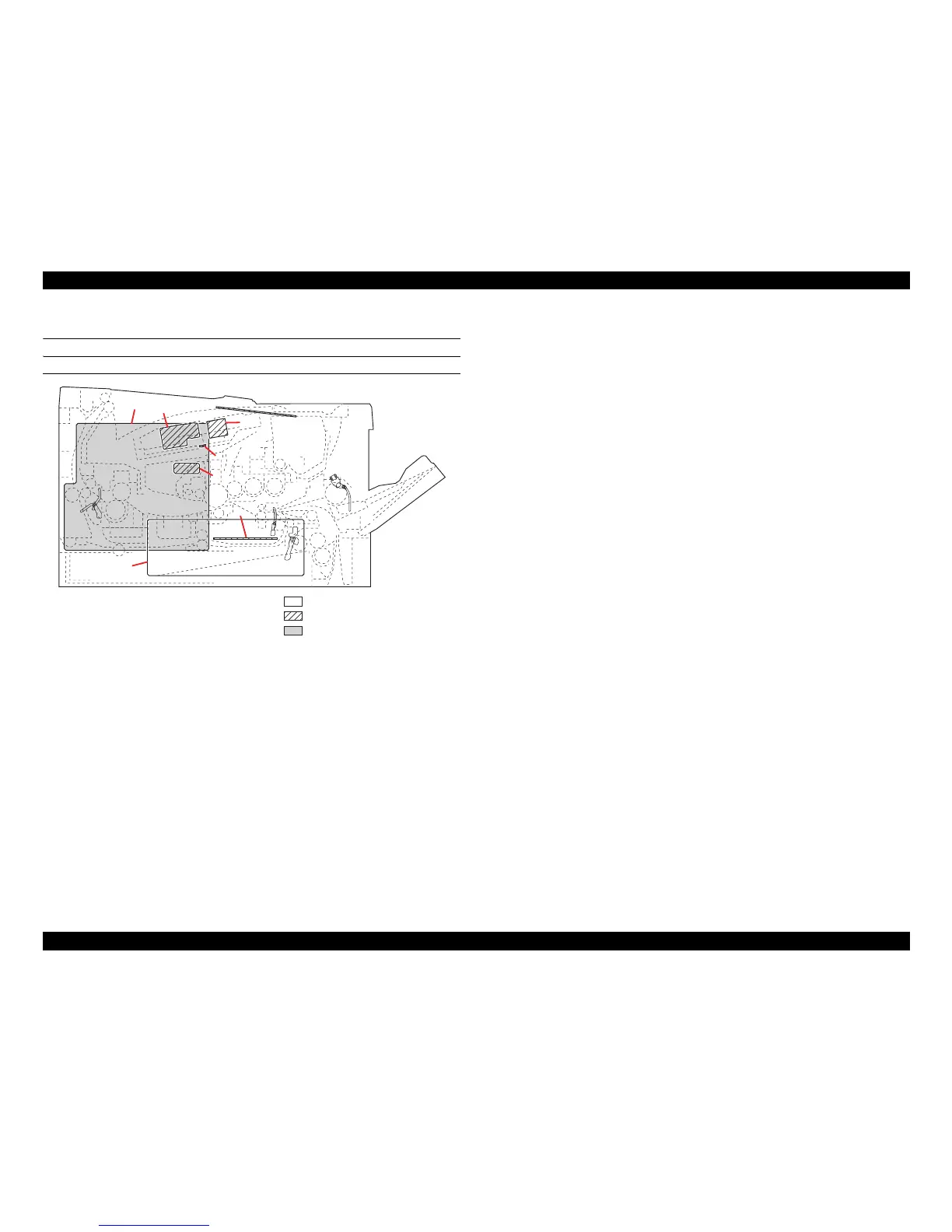

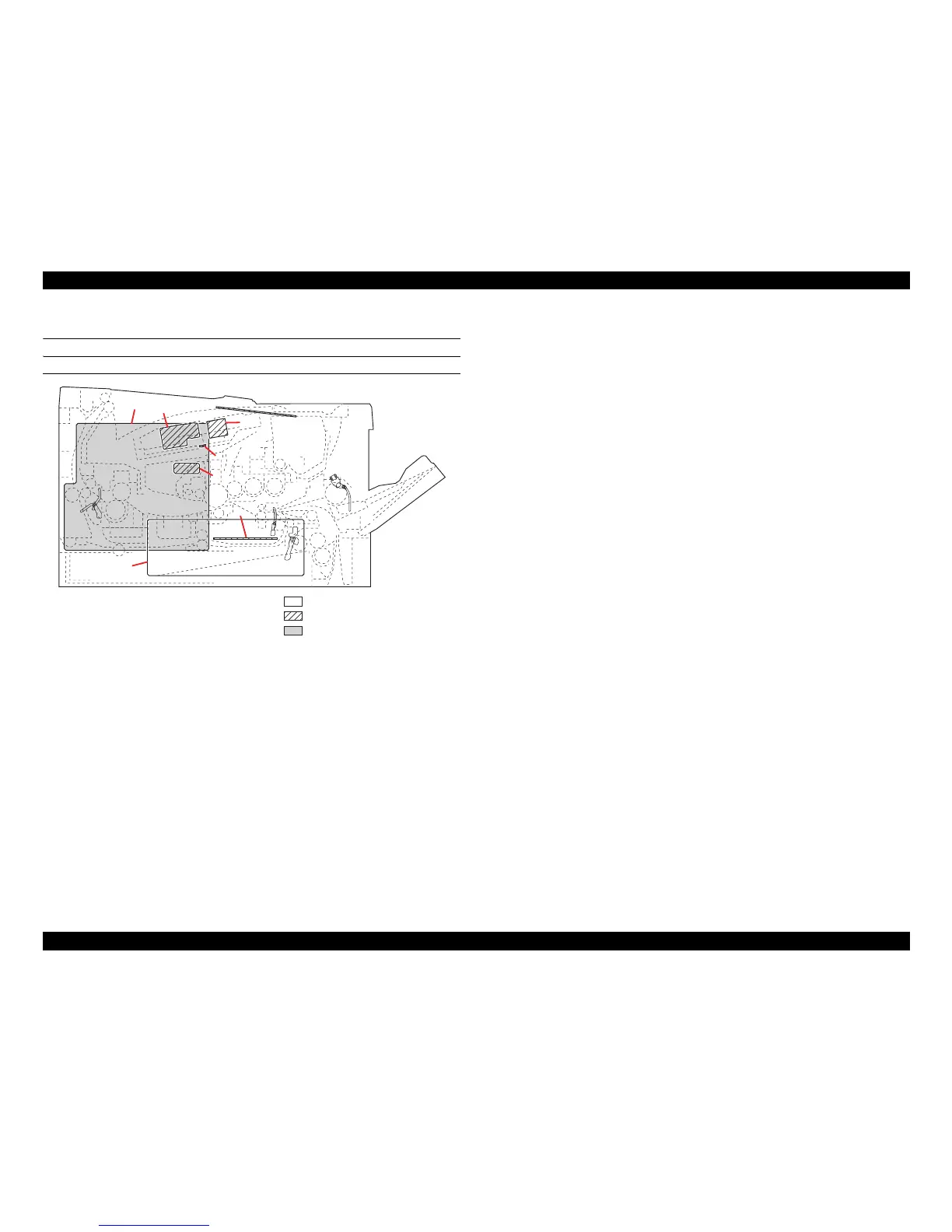

2.1 Electrical parts layout

POWER WRITING BOARDS

Figure 2-1. Power Writing Boards

1. Main Board Assy.

Main controller section:

Controls the software such as the print data processing and provides the

interface with computers.

Engine section:

Controls printer hardware such as high voltage/bias output control, paper

conveying system control, and fuser temperature control, etc.

2. LVPS

After full-wave rectification of AC power source input, switching for converting

to 24 V DC for output. Controls the fuser heater lamp.

3. HVPS

Generates main charging, developing bias, transfer bias.

4. Control Panel Board

Consists the LED indicators and key switches.

5. APC PWB

Generates and controls the laser beam.

6. PD PWB

Controls horizontal synchronizing timing of laser beam.

7. Zener PWB

Adjusts the drum surface potential.

8. Eraser lamp PWB

Eliminates the residual electrostatic charge on the drum.

Machine inside

Machine left

Machine right

1

2

3

5

7

8

6

4

Loading...

Loading...